Venturi scrubber with changeable structure

A technology of Venturi scrubber and Venturi tube, which is applied to the purification of liquid scrubbing gas, chemical instruments and methods, and the removal of gas pollutants, etc., can solve the problems of increasing the investment cost and time of decoking, and save investment time and cost, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

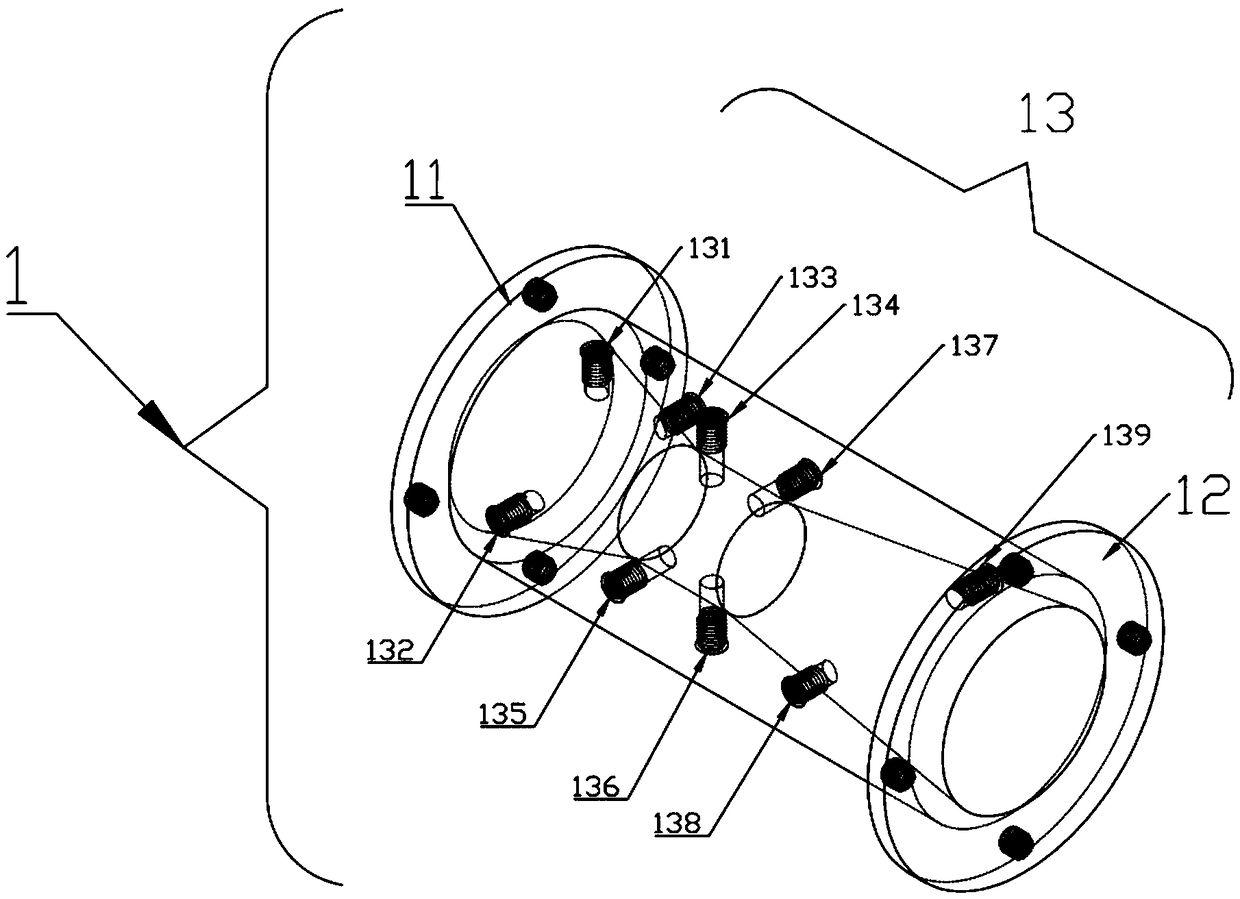

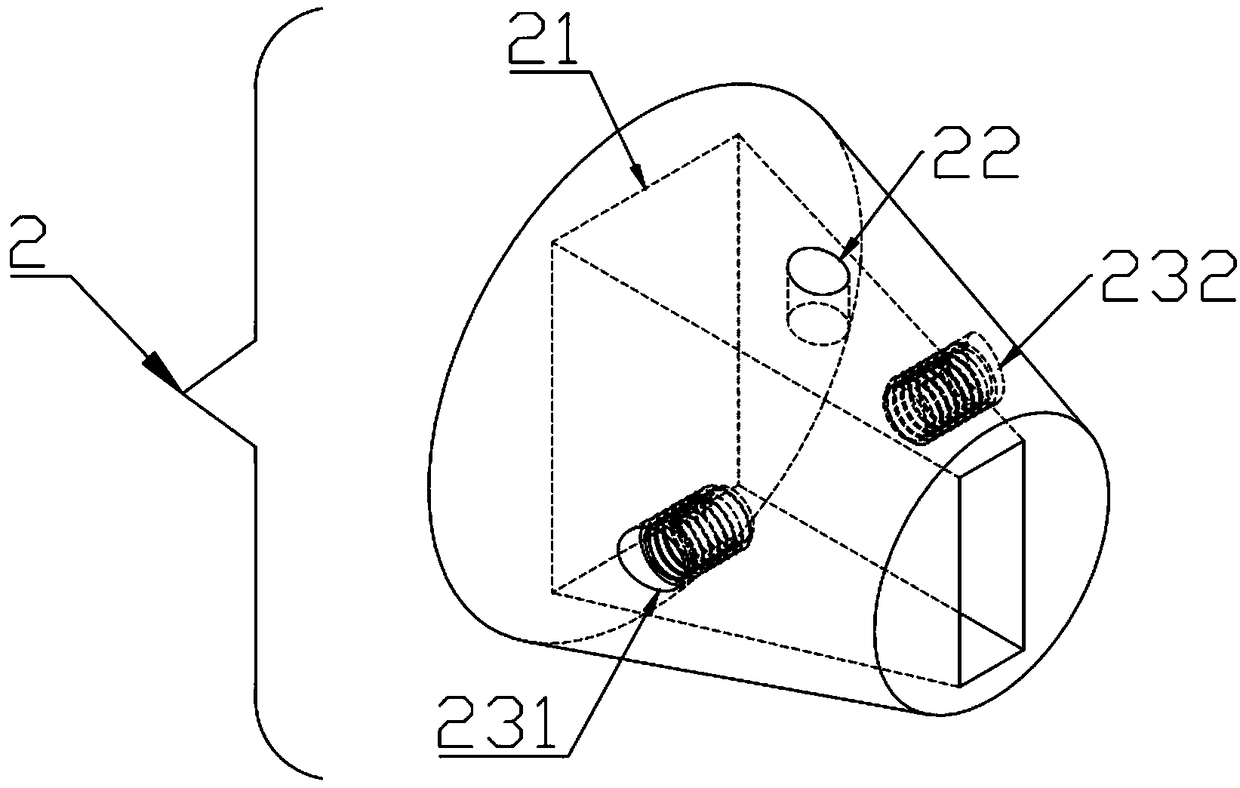

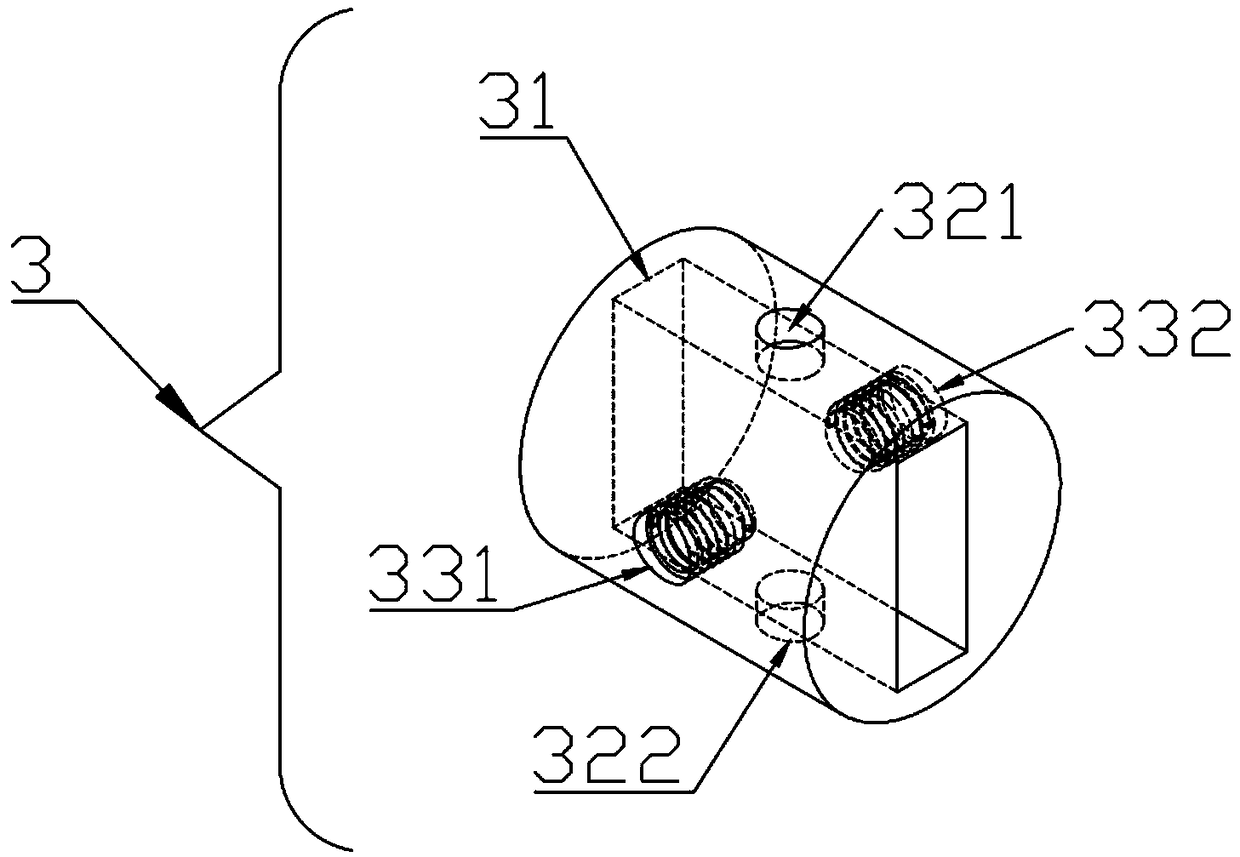

[0038]The present invention is a Venturi scrubber whose structure can be changed, comprising a Venturi tube main body 1, a tapering section module 2, a throat module 3, a diverging section module 4, a middle bolt group 5, a long bolt group 6, a horizontal nozzle Pipe group 7, short bolt group 8 and downstream nozzle pipe 9. Venturi tube main body 1 is provided with inlet flange 11, outlet flange 12 and bolt hole group 13, bolt hole group 13 includes bolt hole a131, bolt hole b132, bolt hole c133, bolt hole d134, bolt hole e135, bolt hole f136, bolt hole g137, bolt hole h138 and bolt hole i139. The tapered section module 2 includes the tapere...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap