Aluminum ring-pull can recycling machine and recycling treatment method thereof

A technology of recycling and cans, which is applied in the direction of presses and manufacturing tools, can solve the problems of limited storage space, recycling quality and cost impact, garbage mixing, etc., and achieve the effect of rapid recycling revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

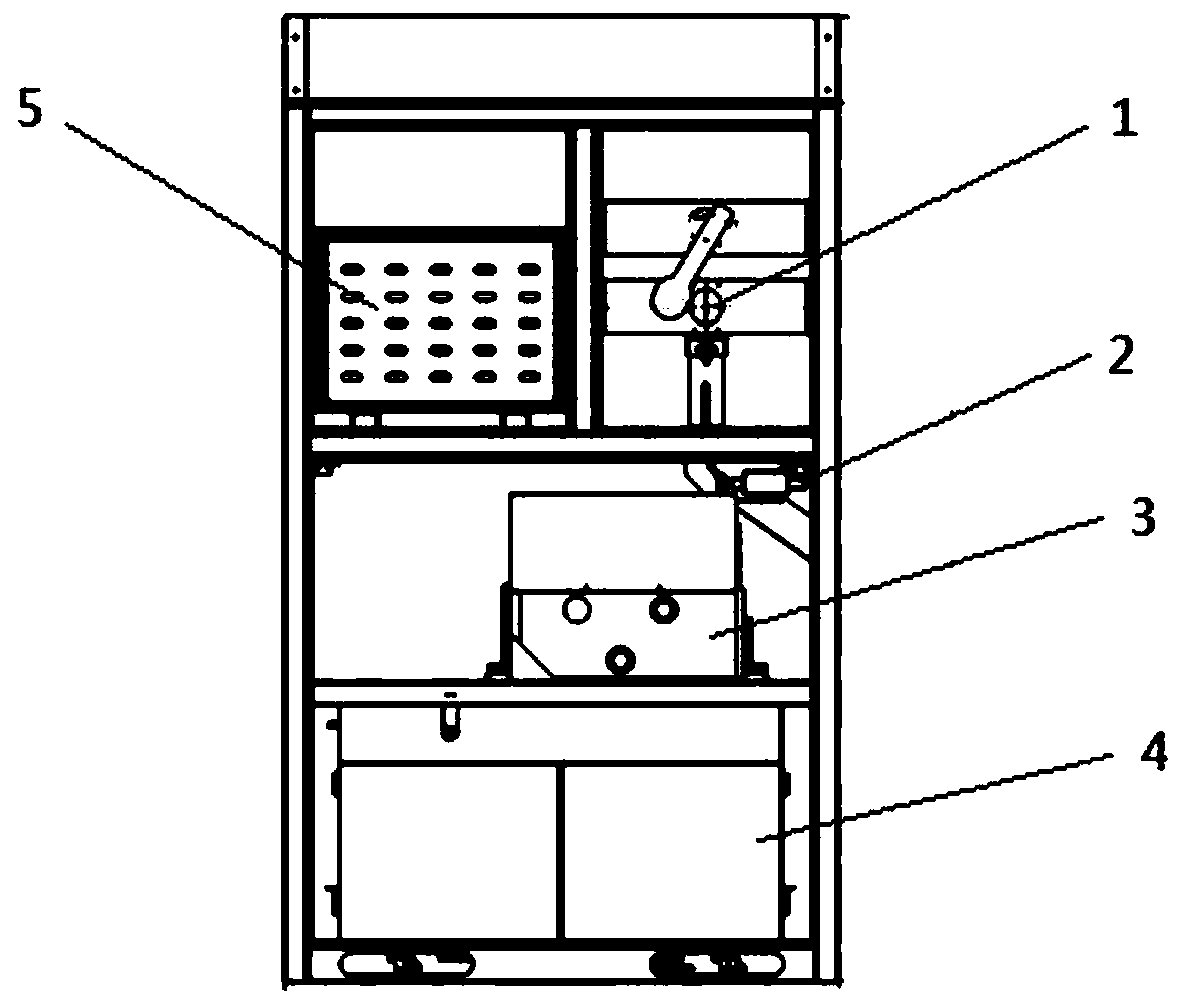

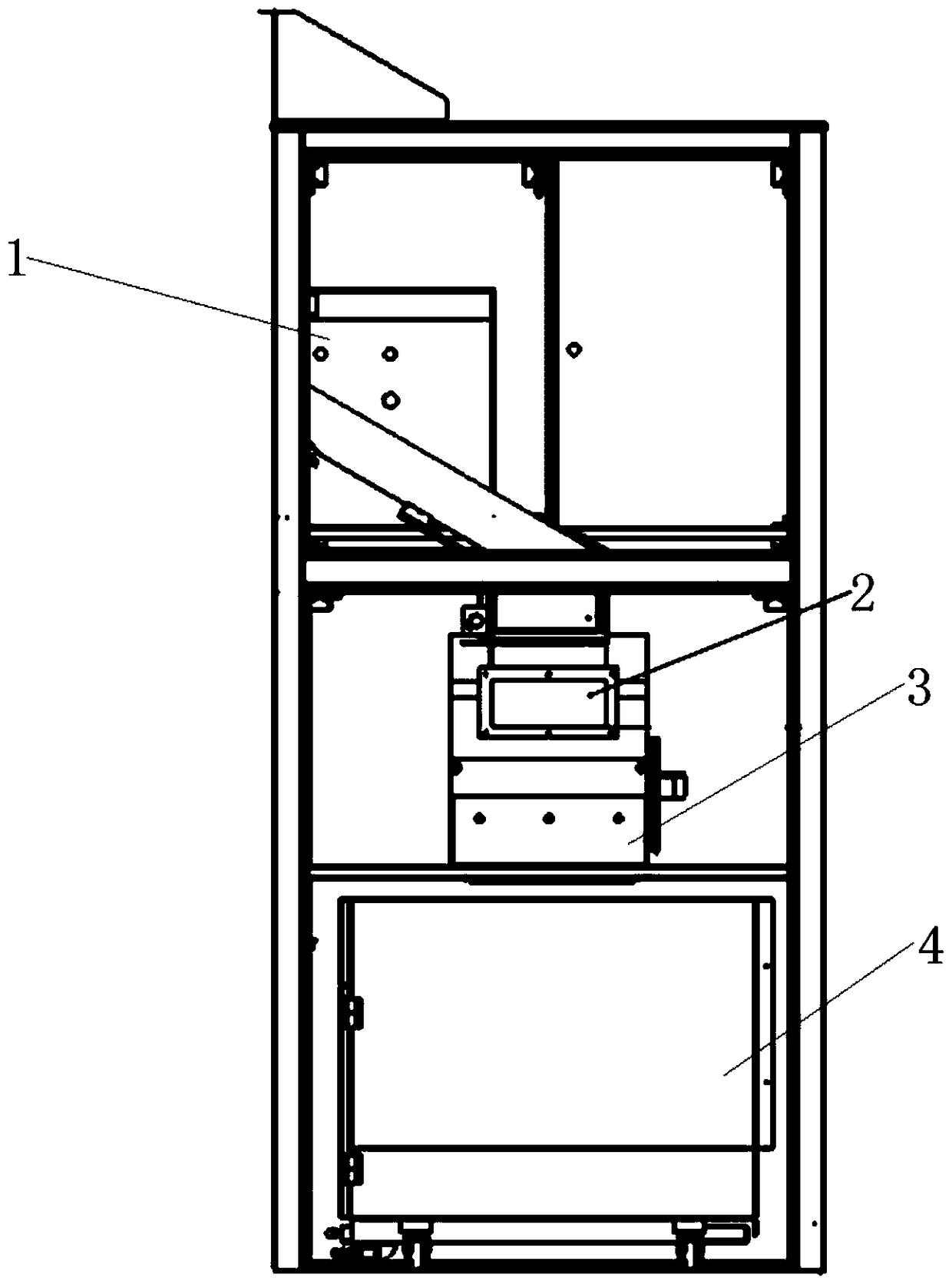

[0042] refer to figure 1 , figure 2 As shown, an aluminum can recycling machine includes an electrical system 5, a delivery system 1, a discharge system 2, a crushing system 3 and a collection system 4, and the delivery system 1 is connected to the discharge system 2 and the crushing system 3 respectively. , the crushing system 3 communicates with the collection system 4, and the electrical system 5 controls the other four systems.

[0043] The electrical system 5 includes a display screen, a power supply and a processor.

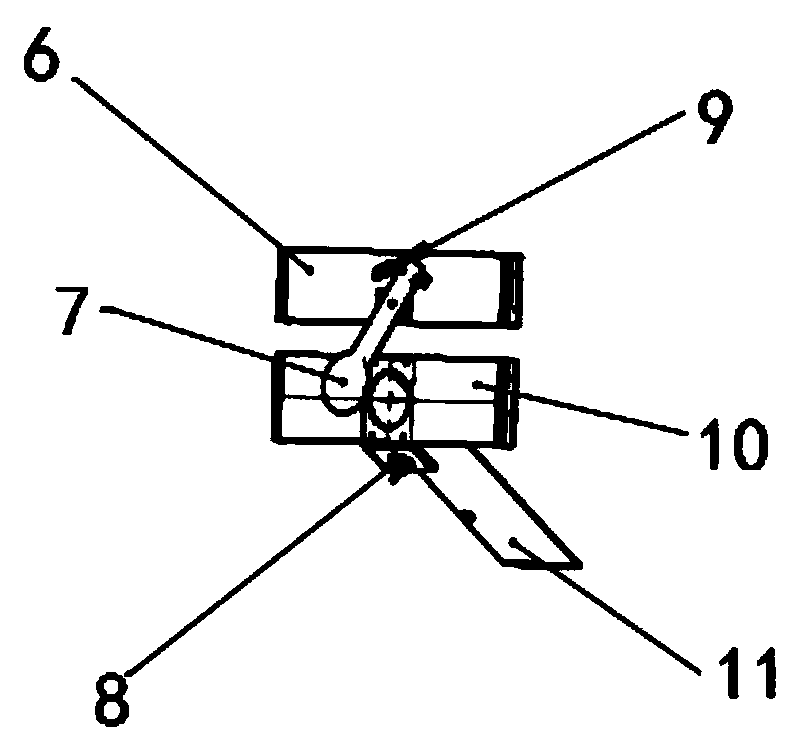

[0044] refer to image 3 As shown, the delivery system 1 is divided into an upper liner 6 and a lower liner 10, the upper liner 6 is axially connected to the feeding valve sheet 7, the lower liner 10 is provided with a feeding pipe 11, and the feeding valve The sheet 7 blocks the mouth of the feeding pipe 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com