Bottle body processing base for gilding

A bottle body and bottom plate technology, applied in printing, rotary printing machines, printing machines, etc., can solve problems such as damage, hot stamping operation failure, bottle body misalignment, etc., and achieve the effects of convenient use, accurate positioning, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

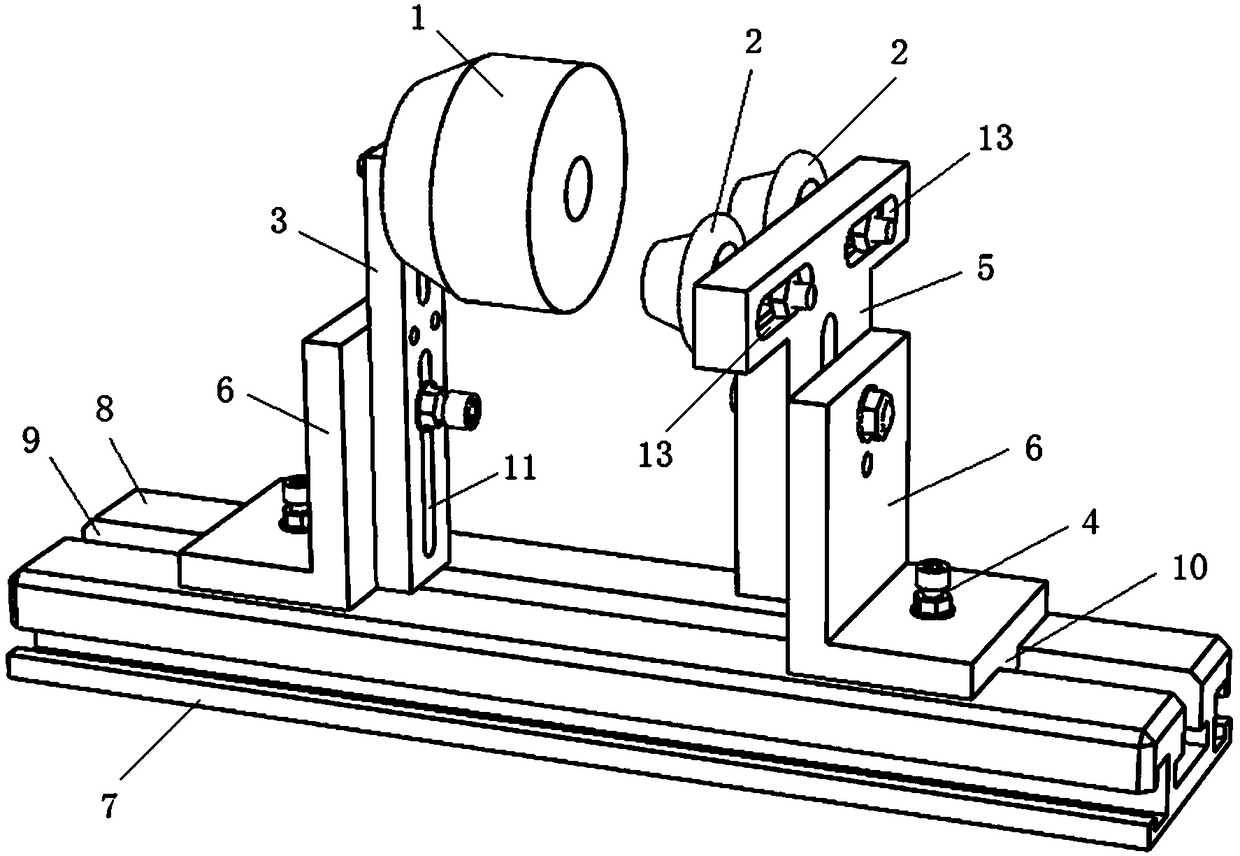

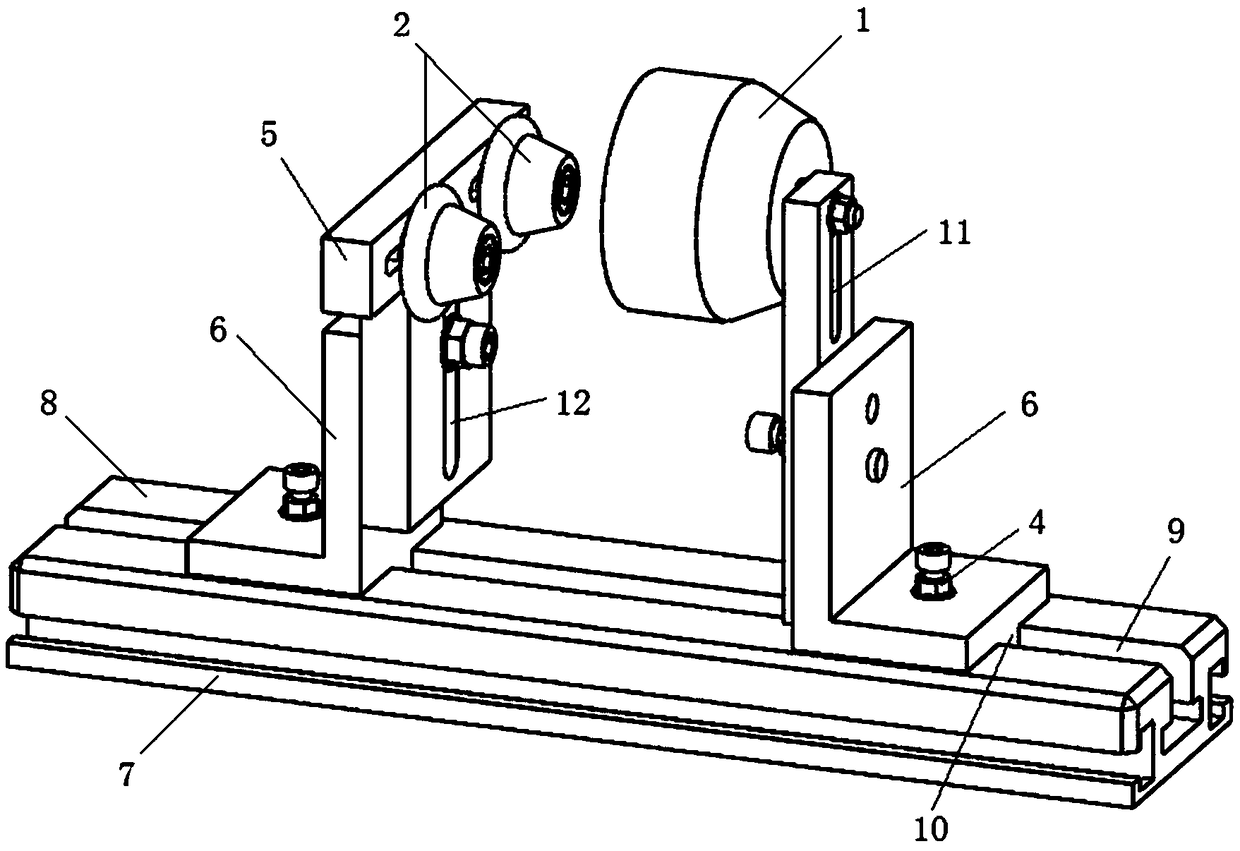

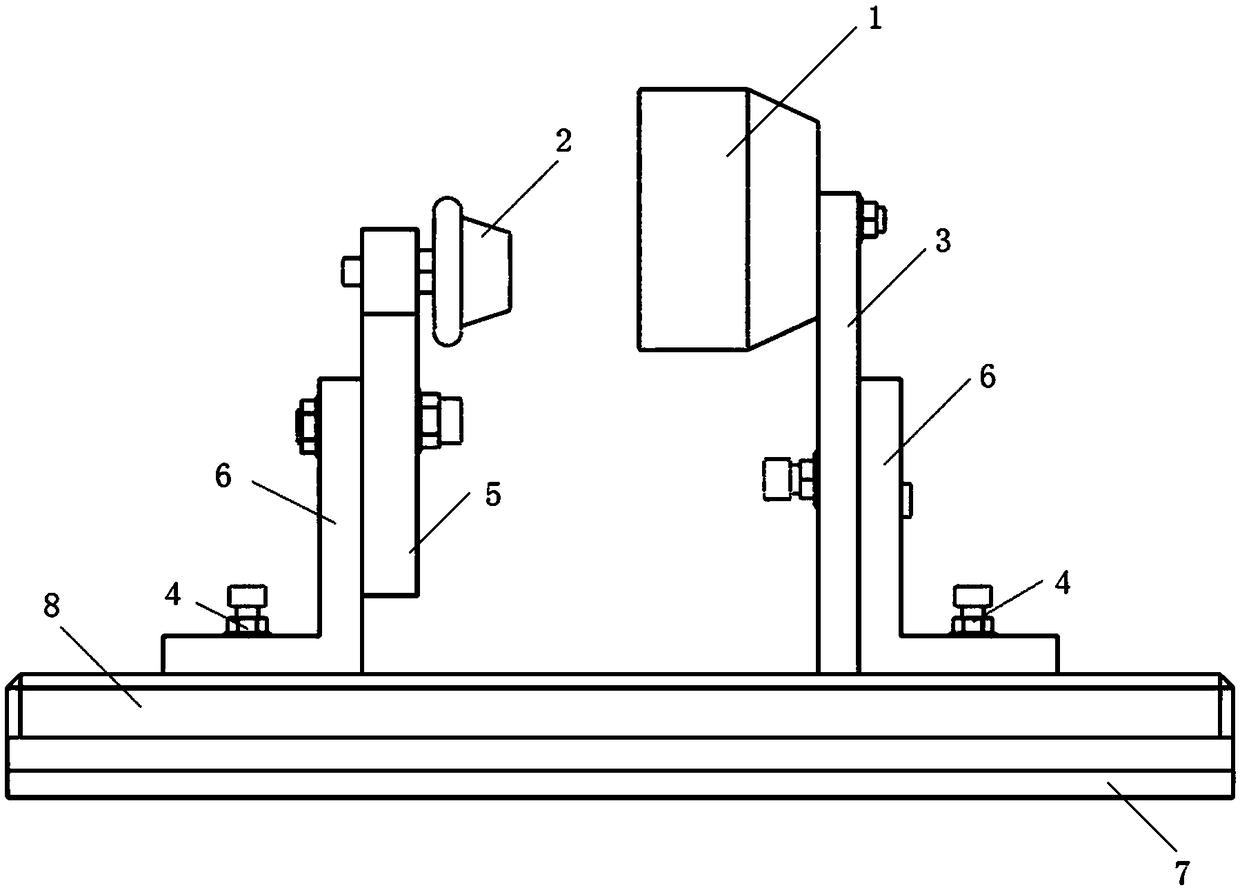

[0026] Such as Figure 1 ~ Figure 3 As shown, the present invention relates to a bottle body processing base for bronzing. The bottle body processing base includes a bottle mouth fixing member 1, a bottle body support member 2, a bottom plate 7, a slide rail 8, a strip-shaped fixing plate 3, and a T-shaped fixing plate 5 and L-shaped support plate 6. The bottle body of the bronzing bottle to be processed lies on the bottle body processing base of the present invention, the bottle mouth fixing part 1 is used to support the bottle mouth of the bottle body to be processed, and the bottle body support part 2 is used to support the bottle body to be processed after lying on the side bottle body. The slide rail 8 is integrally formed with the bottom plate 7, and the slide rail 8 is provided with a chute 9 with a strip structure. The bottom of the horizontal plate 601 of the L-shaped support plate 6 is provided with a protruding slider 10 , which is a rectangular block structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com