AGV with flexible lifting function

A flexible and trolley technology, applied in the direction of lifting devices, etc., can solve problems such as the contradiction between lifting speed and impact control, and the construction cost of the lifting machine is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

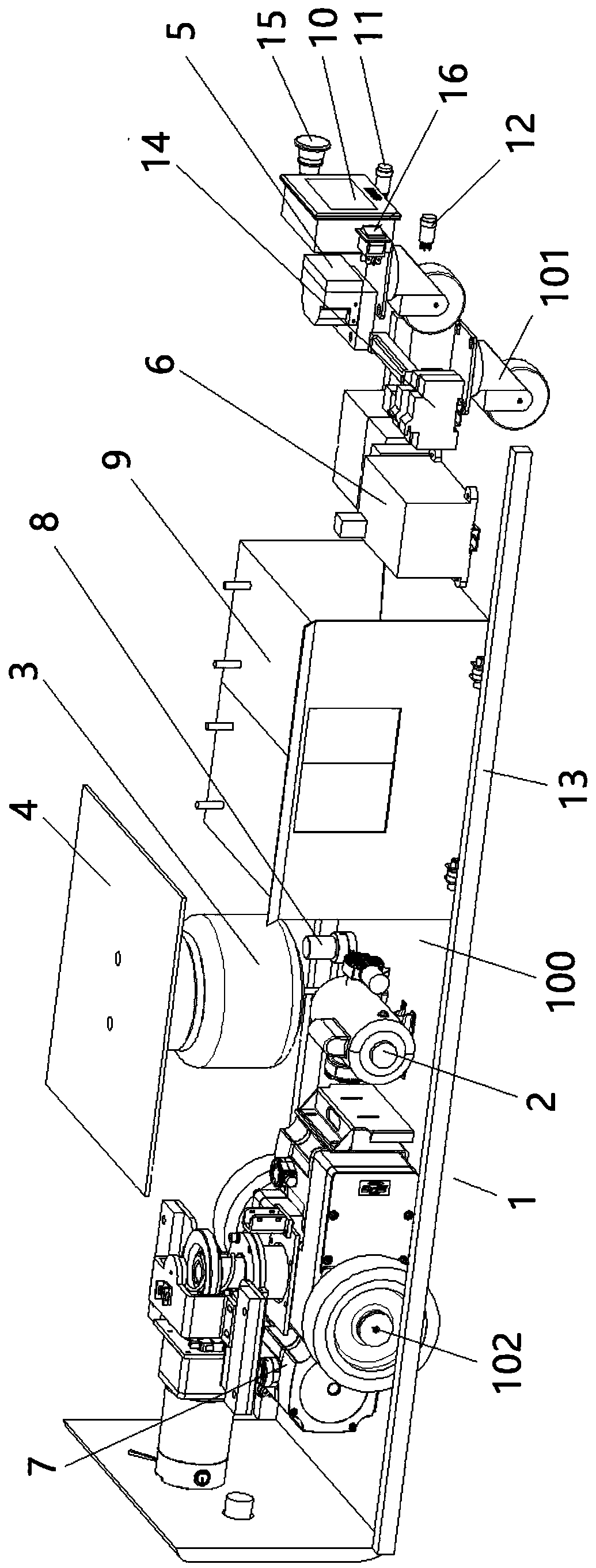

[0039] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0040] see figure 1 , the present invention provides an AGV trolley with flexible lifting, which can shuttle in industrial production workshops and logistics transportation industries, and can provide a good solution for the transportation of goods in narrow spaces. Specifically, it can be operated without manual control , The trolley that automatically carries goods according to the preset road strength, especially the car that can realize flexible lifting. Under the premise of increasing the lifting speed, the impact can also be low. It is suitable for handling fragile goods or goods with high seismic requirements.

[0041] In a specific embodiment, the AGV trolley with flexible lifting includes a mobile chassis 1, a lifting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com