Construction method of large-span continuous rigid frame beam with support rotating body without cast-in-place section

A construction method and long-span technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as existing lines affecting safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

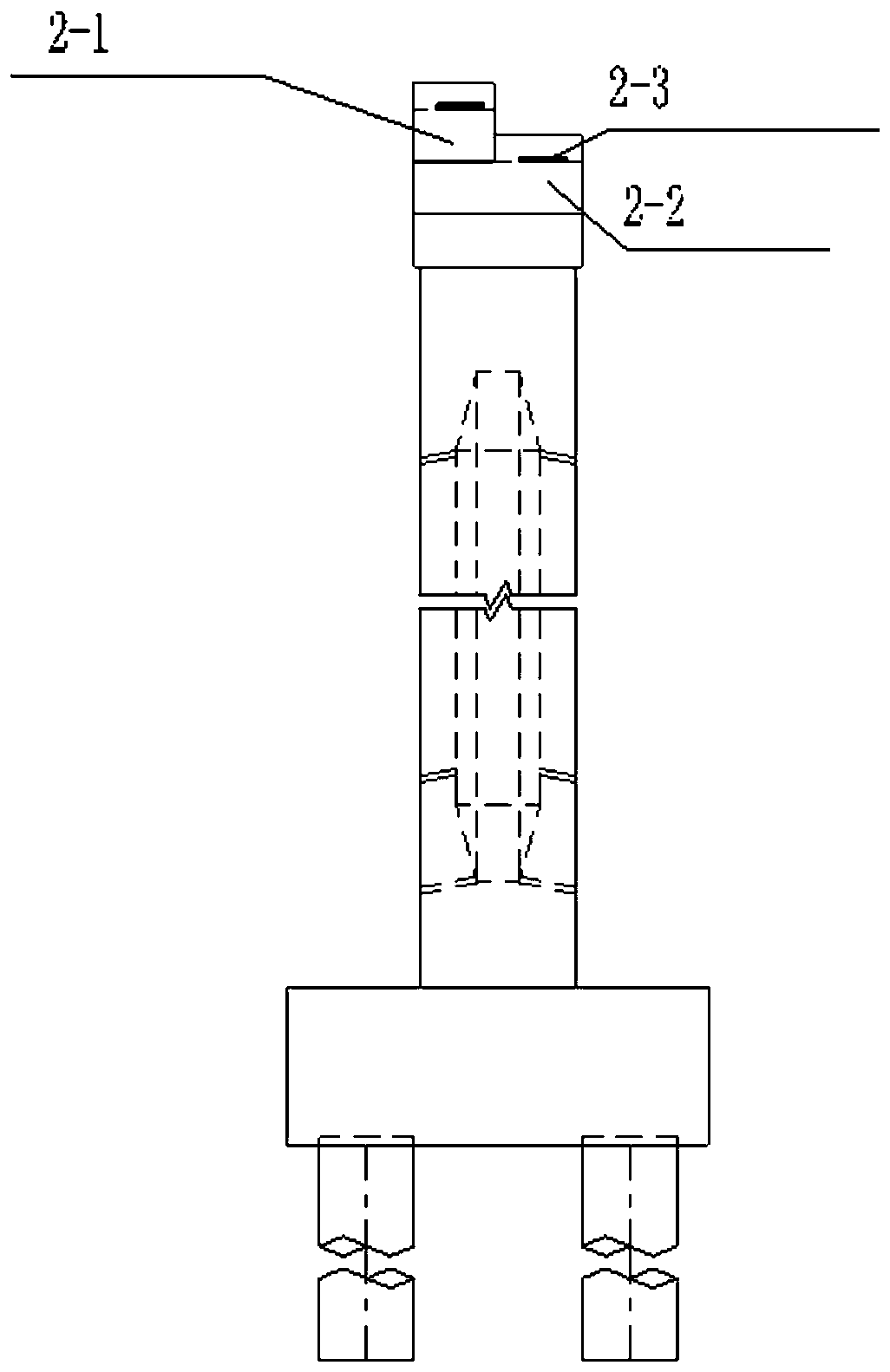

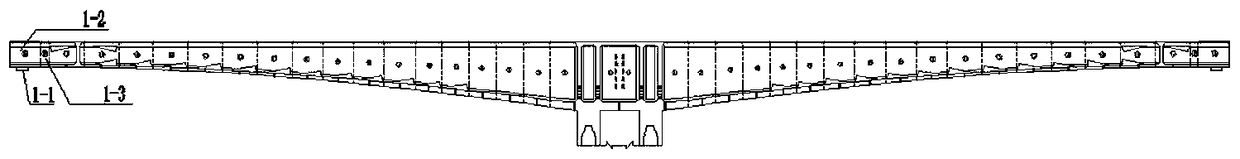

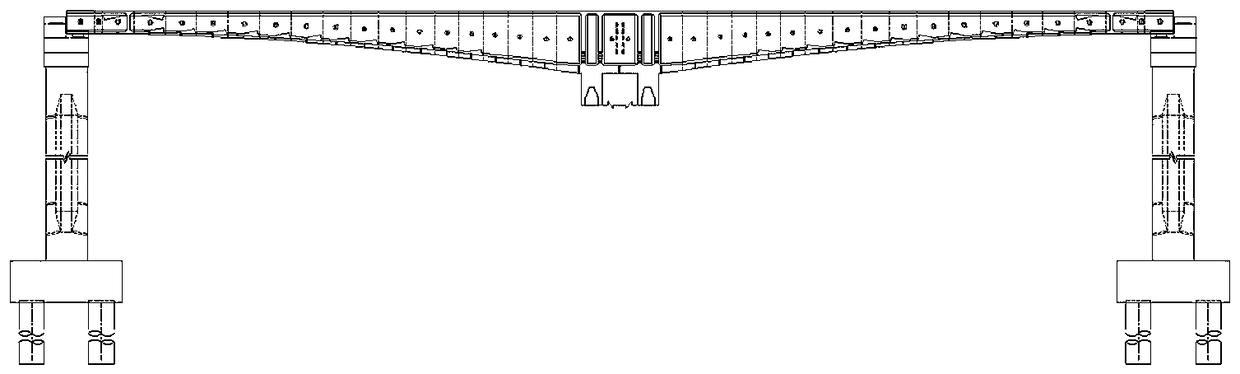

[0014] Such as figure 1 , 2 The large-span continuous rigid-frame beam without cast-in-place section shown in 3 and 3 includes the beam body formed by pouring the side-span cast-in-place section 1-2 and several closing sections 1-3, and the transition support beam body Side pier, side span cast-in-place section 1-2 is poured with pre-buried support 1-1 at the bottom, and the top of the side pier is equipped with high cover beam 2-1, low cover beam 2-2 and support pad stone 2-3, the high The cover beam 2-1 and the support pad stone 2-3 are installed above the low cover beam 2-2, and the support pad stone 2-3 is located inside the high cover beam 2-1 and is lower than the high cover beam 2-1. The buried support 1-1 is supported and installed on the support pad stone 2-3, and the side span cast-in-place section 1-2 is limitedly installed on the inner side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com