Half-through space Y-shaped steel box arch bridge cable hoisting method

A cable hoisting and mid-support technology, applied in arch bridges, bridges, suspension bridges, etc., can solve problems such as affecting the progress of the project, economic losses, and affecting the wide application of the cable hoisting system in V-shaped canyons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

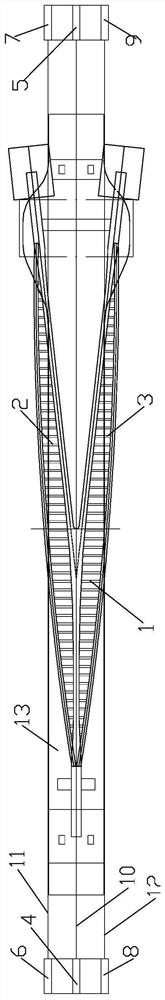

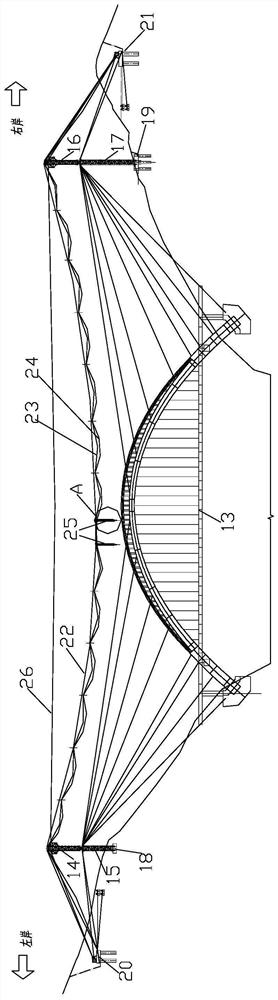

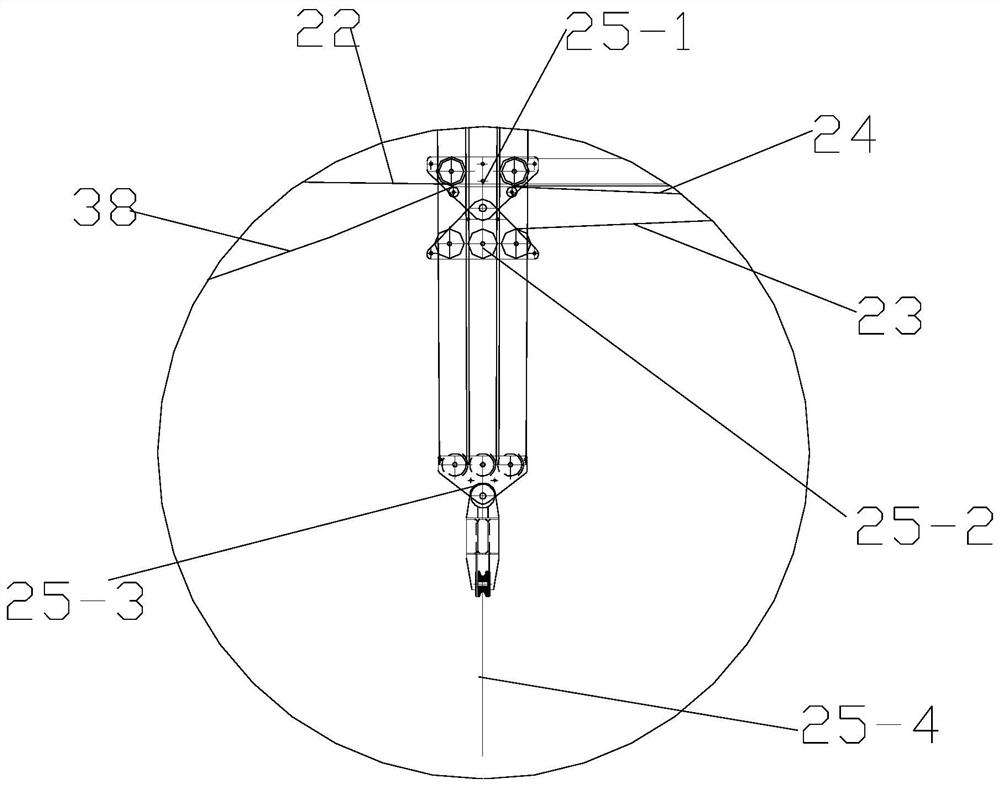

[0070] like Figure 1 to Figure 7 As shown, a kind of in-support type space Y-shaped steel box arch bridge cable hoisting method of the present invention comprises the following steps:

[0071] Step 1. Determine the cable hoisting system of the Y-shaped steel box arch bridge in the middle space: determine the cable hoisting system of the Y-shaped steel box arch bridge in the middle space. The cable hoisting system of the Y-shaped steel box arch bridge in the middle space includes the left bank main tower set on the left bank frame 4, and the first sub-tower 6 on the left bank and the second sub-tower 8 on the left bank located on both sides of the main tower on the left bank; The first auxiliary tower 7 on the right bank matched with the auxiliary tower 6, the second auxiliary tower 9 on the right bank matched with the second auxiliary tower 8 on the left bank, and the main arch cable is arranged between the main tower 4 on the left bank and the main tower 5 on the right bank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com