A split-start construction method for double-line shield tunneling in ultra-deep circular shafts

A split origination and construction method technology, applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problem of pipeline extension, fixation, pressure maintenance protection, difficult maintenance, and splitting of ultra-deep circular shaft double-line shield The problems of long initial construction period and large loss of oil pressure and water pressure have achieved the effect of simple and convenient construction method, reduced construction risk and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

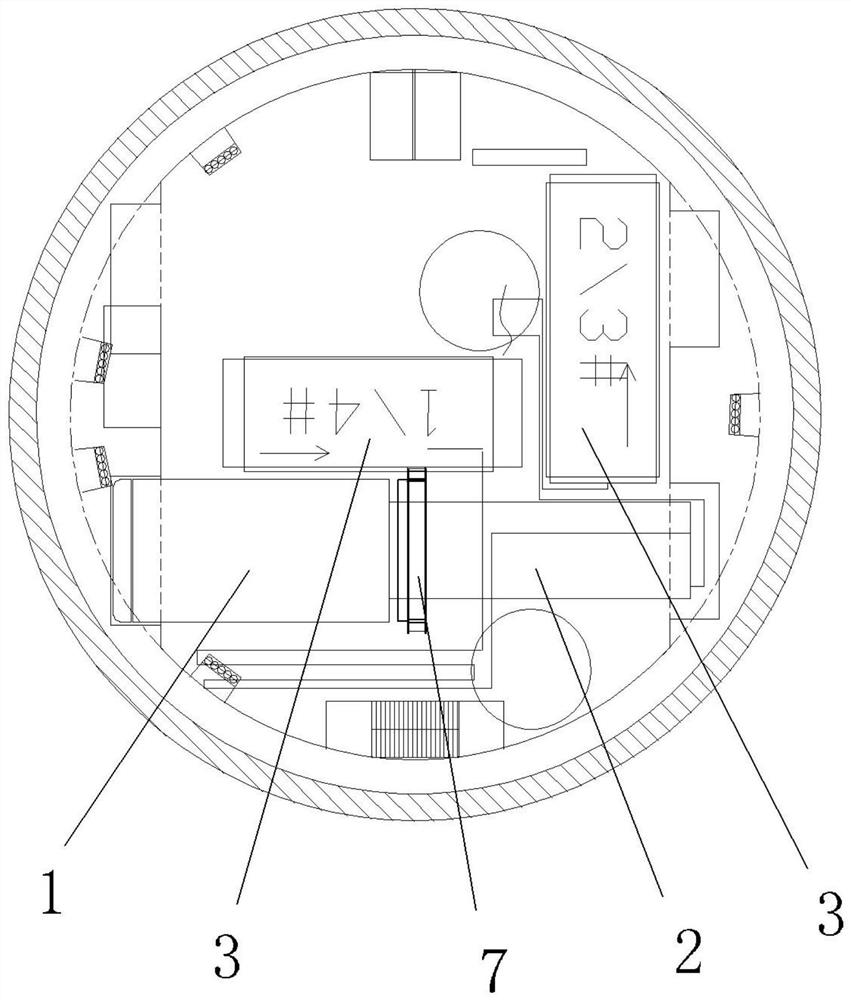

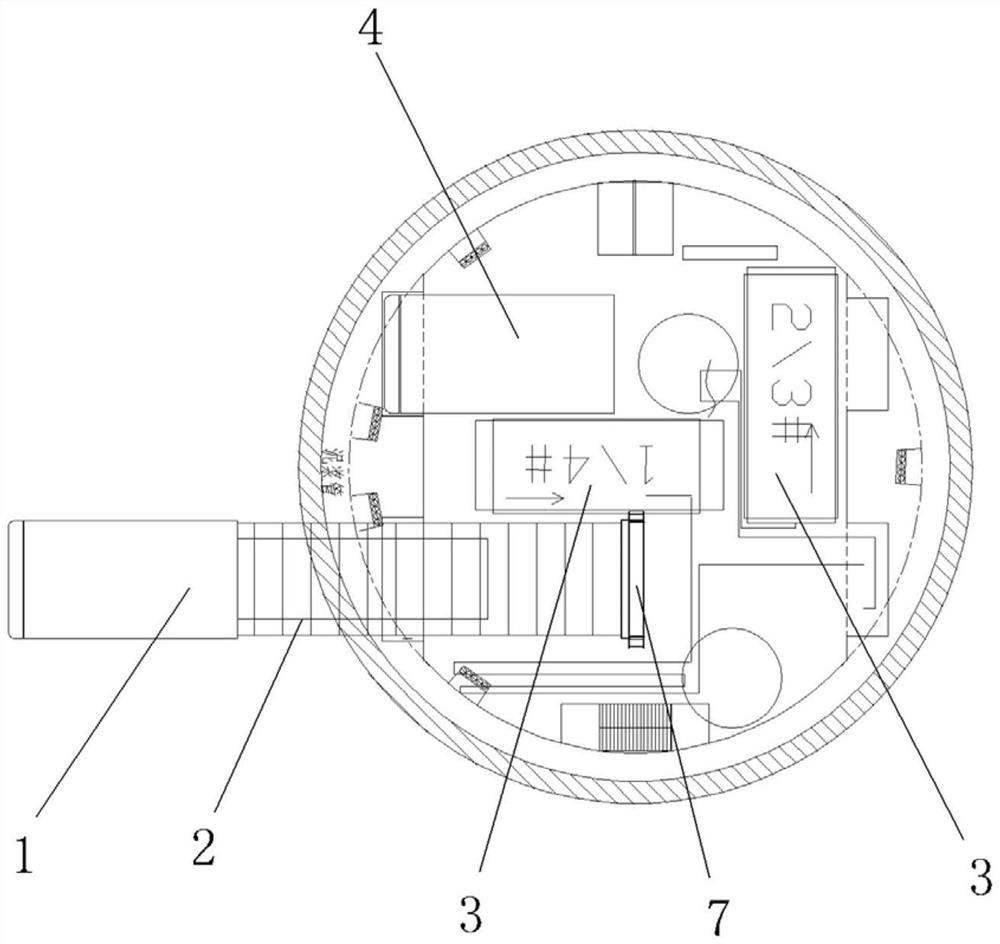

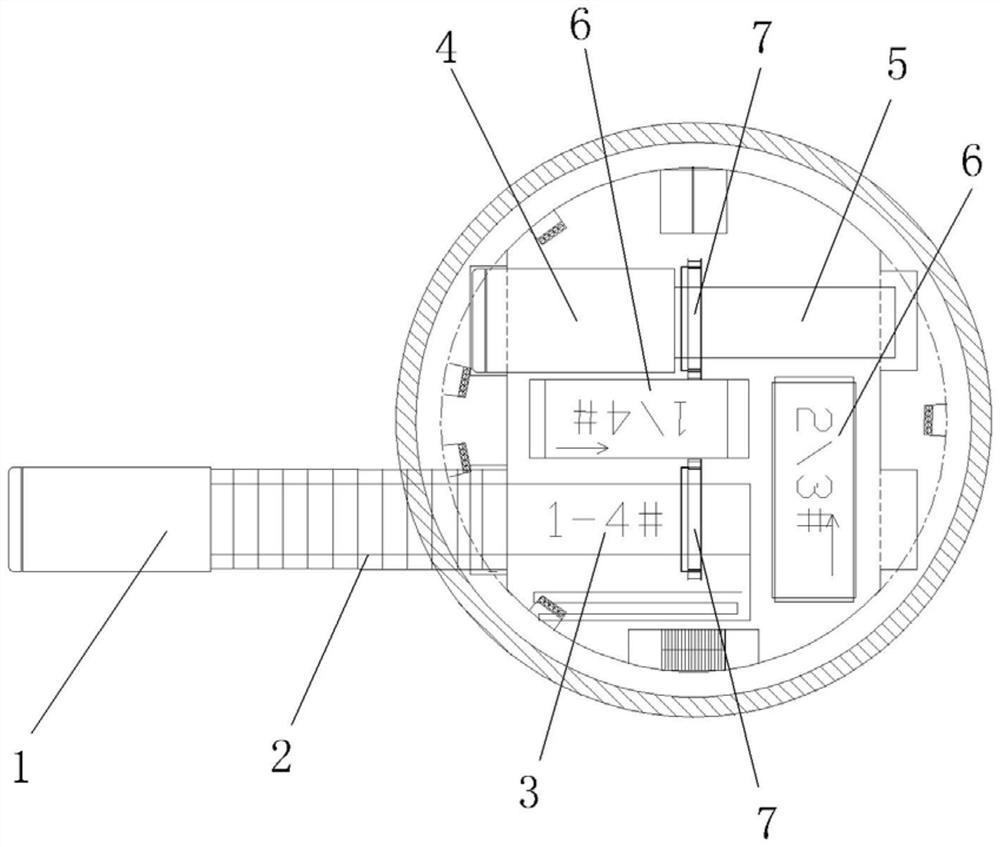

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0034] An ultra-deep circular shaft double-line shield split start construction method, comprising the following steps:

[0035] Step 1: The construction of the starting working well of the ultra-deep circular shield is completed, including the first area and the second area where the left and right lines are set. Make construction preparations, make safety technical disclosure to the shield starting construction personnel, confirm that the setting of the embedded parts of the bottom plate is accurate, and confirm that the starting bracket goes down to the fixed elevation, level, and axis position is accurate. In the first area, the first shield machine 1 is assembled in the order of the middle shield, the front shield, the cutter head, the assembling machine, the shield tail, and the connecting bridge 2 in sequence.

[0036] Step 2: On the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com