Rotary hinged device load test device

A technology of rotating hinge and load test, which is used in measuring devices, elasticity testing, railway vehicle testing, etc., can solve the problems of inability to apply force in the direction of torsion, inaccurate test results, etc., and achieve the effect of accurate mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

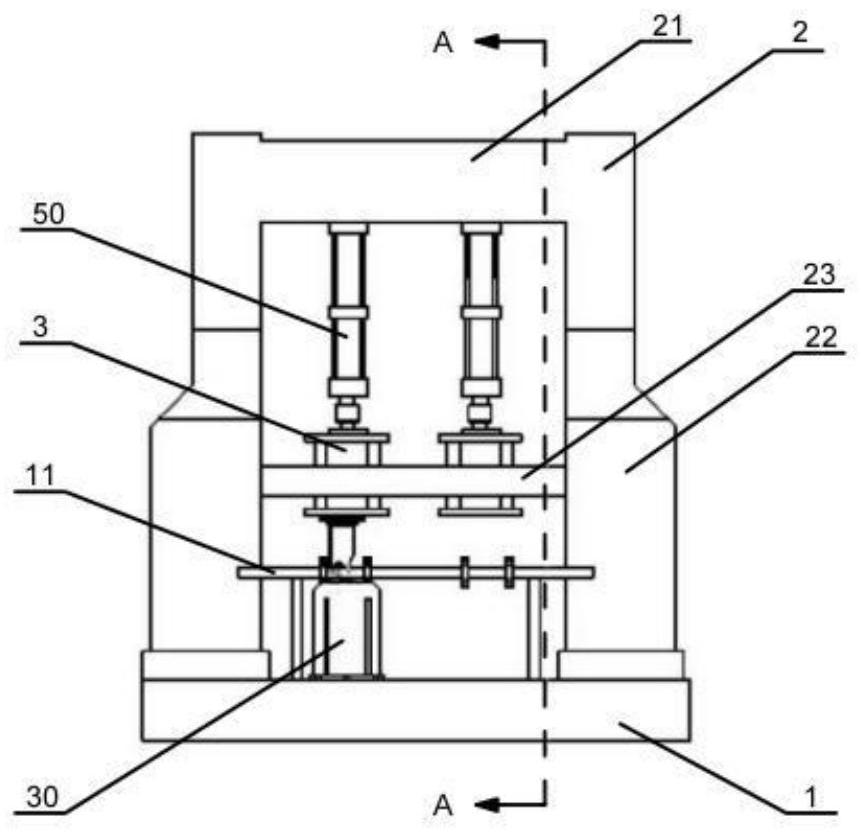

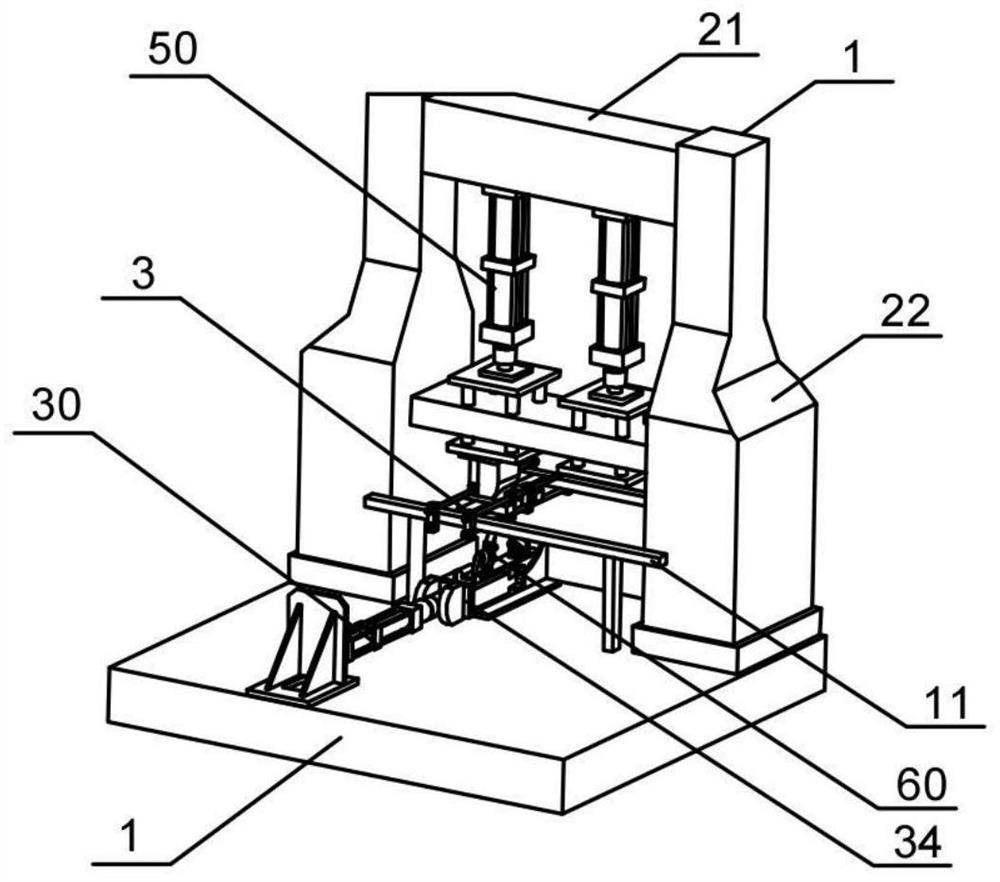

[0037] figure 1 Schematically showing a rotary hinge load test apparatus according to an embodiment of the present invention. The swivel joint load test device according to the present invention is especially capable of measuring the load of the swivel joint.

[0038] Such as figure 1 , figure 2 As shown, the load test device for the rotary hinge device of this embodiment includes a platform 1, and the platform 1 is arranged horizontally. The device of this embodiment also includes a frame 2, and the frame 2 is vertically arranged on the platform 1. In this embodiment, the frame 2 includes a beam 21 and two columns 22 . Wherein, the column 22 is fixed on the platform 1, and the two ends of the beam 21 are respectively connected to the upper ends of the two columns 22.

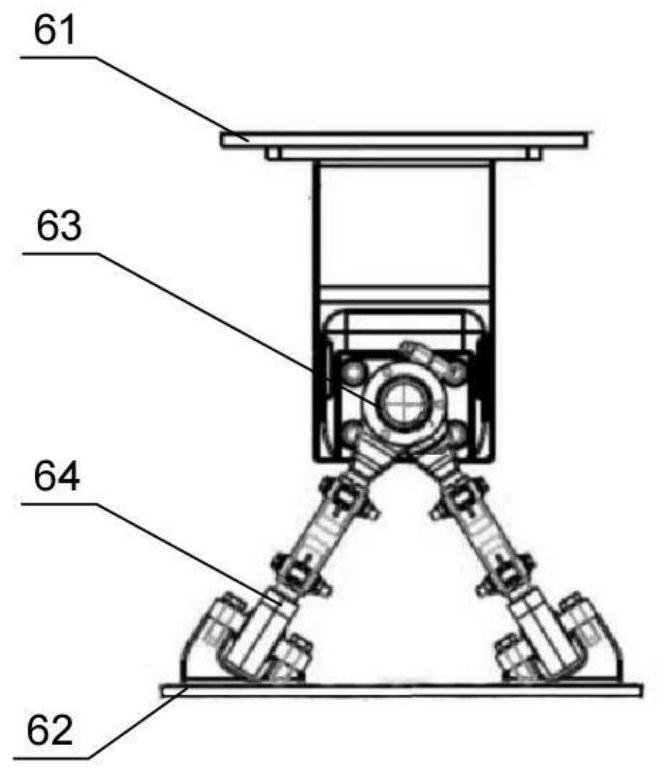

[0039]The device of the present embodiment also includes a two-way loading device 3, and the two-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com