Small-scale architectural plaque stamping processing device

A technology of stamping processing and construction, applied in the field of stamping processing, can solve the problems of large volume of stamping machines, large volume of plates, inconvenience, etc., and achieve the effects of compact size, simple structure and convenient stamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

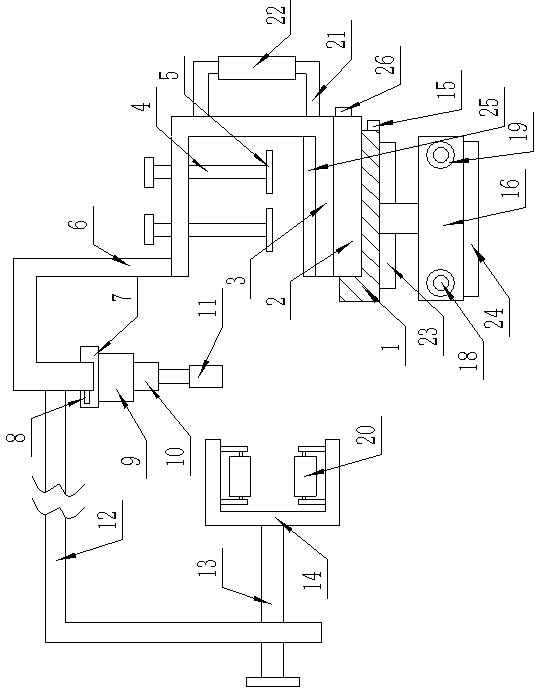

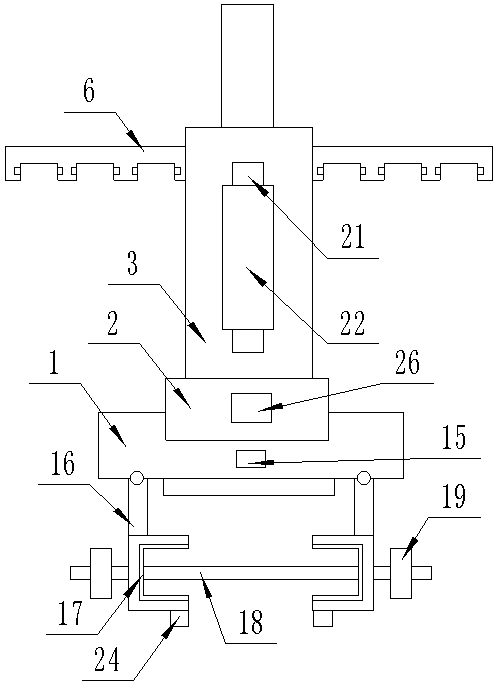

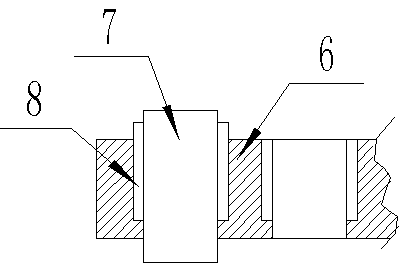

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown in the figure, a small-scale stamping and processing device for architectural decorative panels includes a strip-shaped bearing base 1, a stamping mechanism is provided on the upper surface of the strip-shaped bearing base 1, and a supporting mechanism is provided on the lower surface of the strip-shaped bearing base 1. The stamping processing mechanism is mainly composed of a strip-shaped sliding groove processed at the center of the upper surface of the strip-shaped bearing base 1, a strip-shaped support base 2 arranged in the strip-shaped sliding groove, and a strip-shaped support base 2 arranged on the upper surface of the strip-shaped support base 2. The folded fixed frame 3, a pair of threaded through holes processed on the upper surface of the folded fixed frame 3, the vertical extruded screw rod 4 arranged in each threaded through hole, are sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com