Industrial equipment punching machine with fixing function

An industrial equipment, fixed function technology, applied in metal processing equipment, large fixed members, drilling/drilling equipment, etc., can solve the problems of inability to clamp the plate, unstable fixation, and inability to adjust the punching position, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

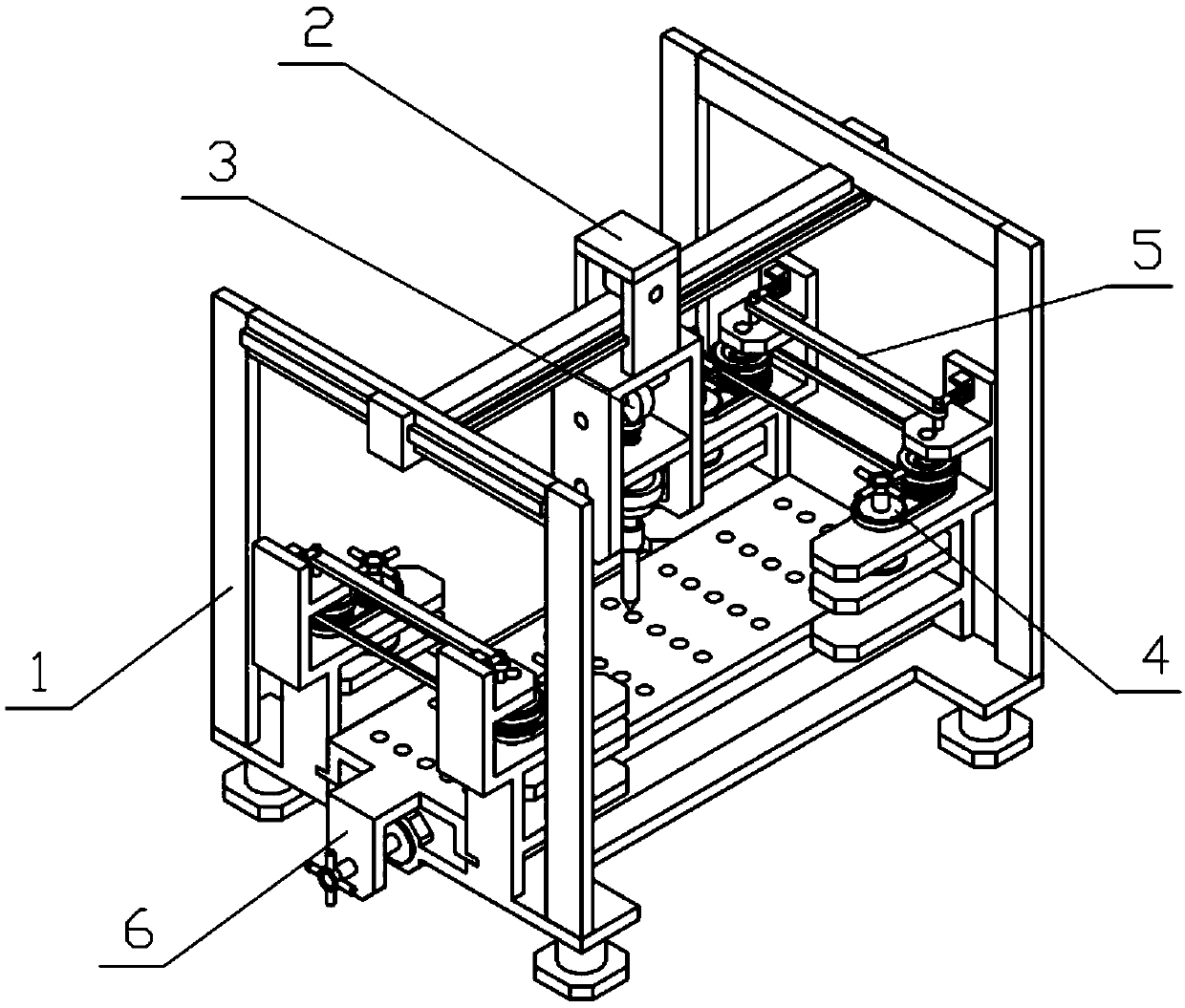

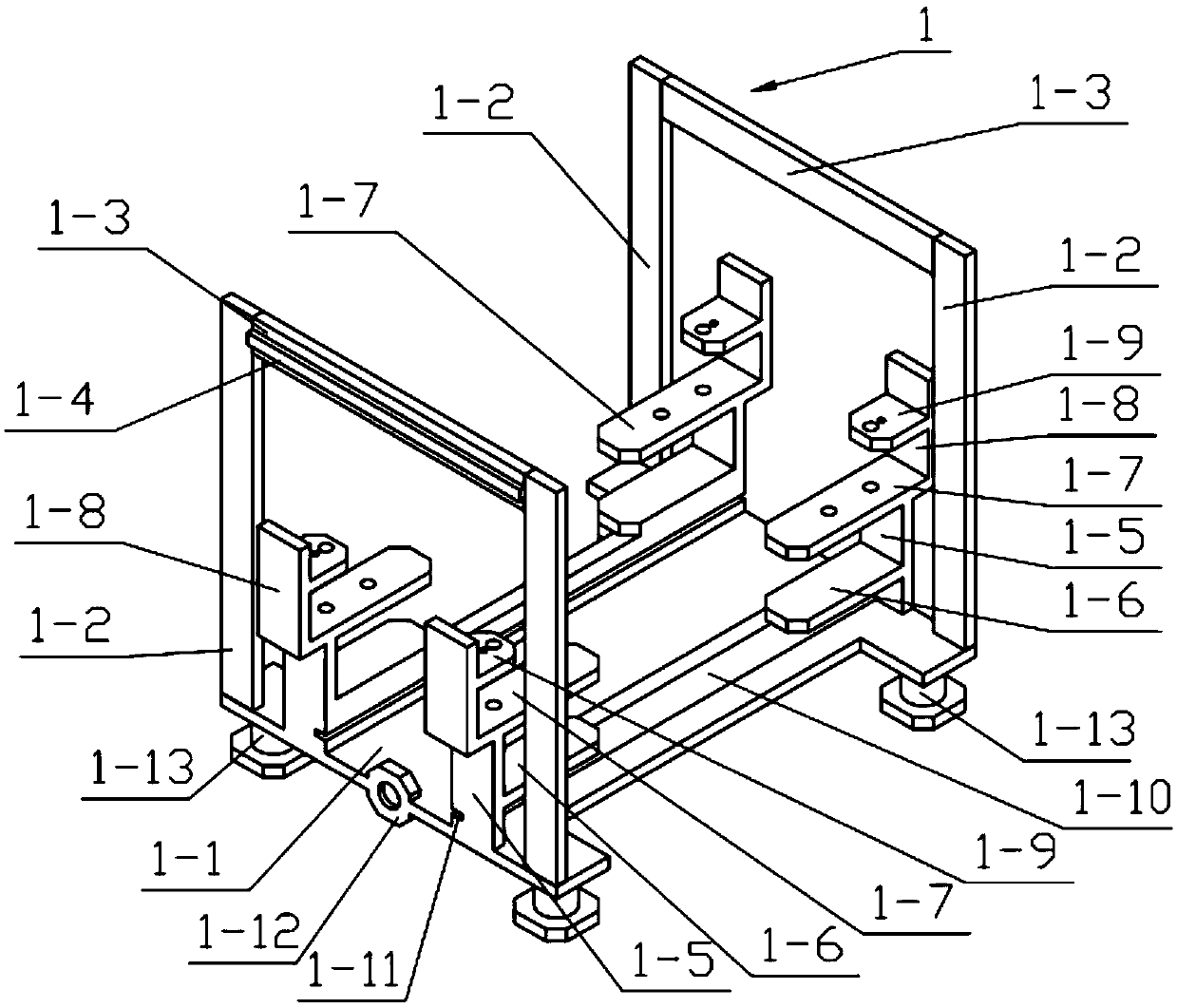

[0033] Combine below Figure 1-10 Describe this embodiment, an industrial equipment punching machine with a fixed function, including an integral bracket 1, an adjustment bracket 2, a punching mechanism 3 and a clamping mechanism 4, which can clamp plates of different thicknesses through the clamping mechanism 4, And the four clamping mechanisms 4 can independently clamp and carry out linkage clamping through the linkage mechanism 5. When the four clamping mechanisms 4 are independently clamped, plates with different thicknesses and shapes can be used, and the four clamping mechanisms 4 can be used through the linkage mechanism. 5. The efficiency of clamping can be increased when performing linkage clamping. By adjusting the bracket 2, the relative position of the punching mechanism 3 can be adjusted, so that the punching position of the punching mechanism 3 can be adapted to different use needs. The punching mechanism 3 can The boards with different thicknesses are punched, a...

specific Embodiment approach 2

[0038] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the integral bracket 1 also includes linkage support plate I1-8, linkage support plate II1-9, sliding plate 1-10, sliding groove 1-11, push bottom plate 1-12 and support feet 1-13, the four clamping top plates 1-7 are fixedly connected with linkage support plates I1-8, and the four linkage support plates I1-8 are all fixedly connected with linkage support plates II1-9, Two sliding plates 1-10 are fixedly connected between the four supporting plates II 1-5, and sliding grooves 1-11 are arranged on the two sliding plates 1-10, and the pushing base plate 1-12 is fixedly connected to the supporting base plate 1-1 On one side of the support base plate 1-1, the four corners of the lower end of the support base plate 1-1 are fixedly connected with support feet 1-13.

specific Embodiment approach 3

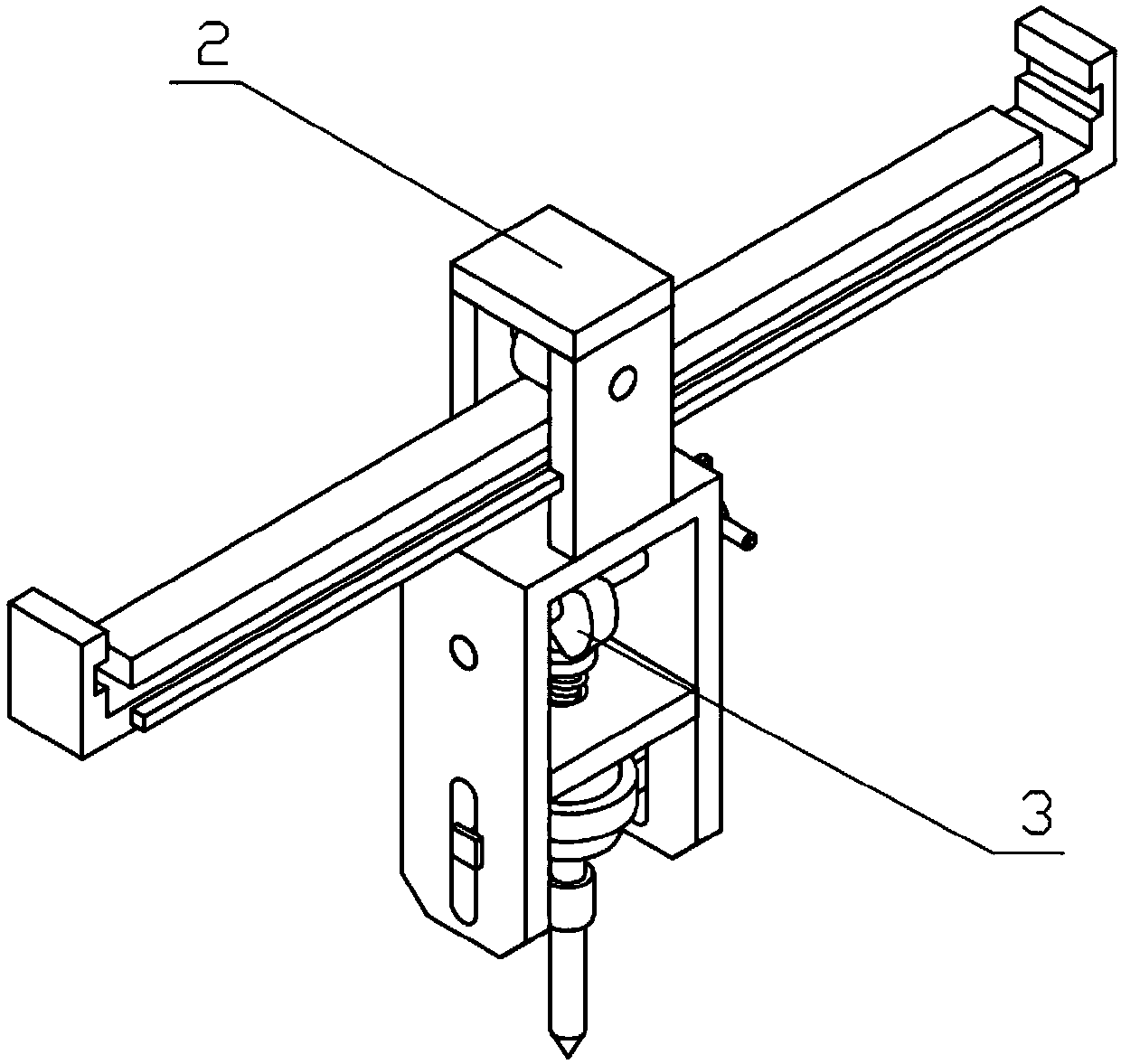

[0039] Combine below Figure 1-10 This embodiment will be described. This embodiment will further describe the second embodiment. The punching mechanism 3 further includes a push handle I3-10, which is fixedly connected to one end of the push shaft 3-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com