An automatic steel turning device

An automatic turning and steel turning technology, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyor objects, can solve the problems of not being able to fully guarantee the 90-degree turning of the steel billet, increasing the amount of manual labor, and increasing labor costs. There are no safety hazards, the effect of reducing the amount of manual labor and improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0017] Example.

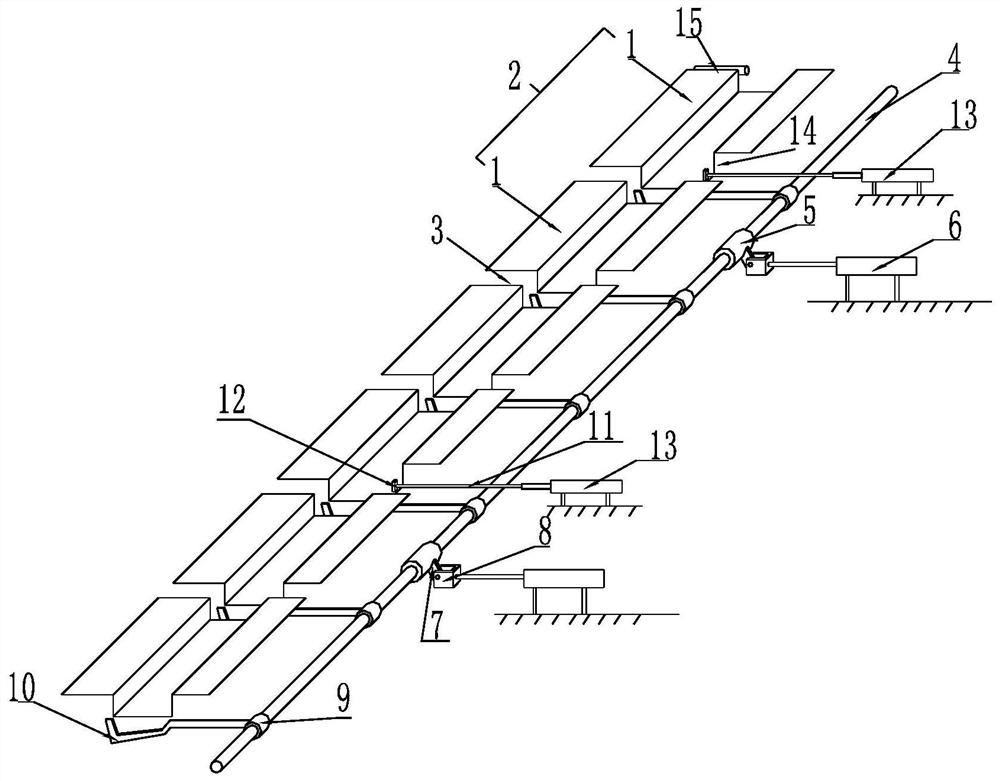

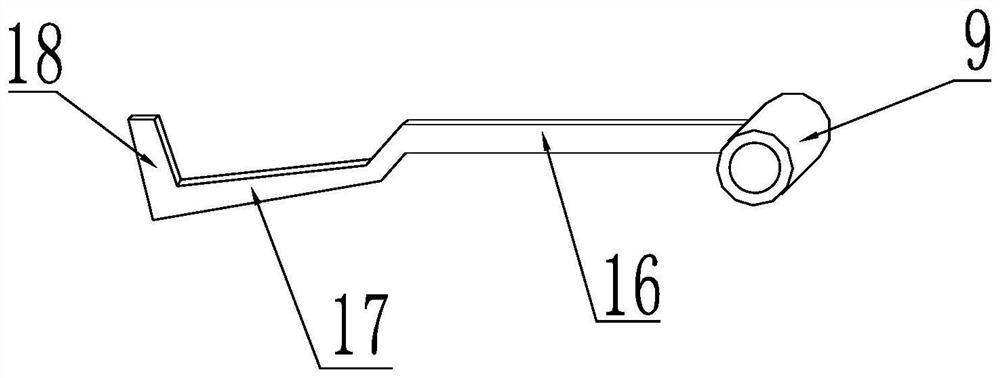

[0018] Such as figure 1 As shown, an automatic steel turning device includes a tapping roller table 2 composed of several rails 1 arranged head to tail, a steel turning gap 3 is left between adjacent rails 1, and one side of the tapping roller table 2 is provided with a The steel roller table 2 is parallel to the turning steel main shaft 4, the turning steel main shaft 4 is connected with the turning steel oil cylinder 6 through the first coupling 5, the first coupling 5 is provided with a connection block 7, and the piston of the turning steel oil cylinder 6 The rod is provided with a connecting seat 8, and the connecting block 7 is hinged with the connecting seat 8; the turning steel hook claw 10 is also connected with the turning steel hook claw 10 through the second coupling 9 on the turning steel main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com