Method for preventing excessive deformation of adjusting roadway at fully mechanized coal mining face retracement stage

A technology of fully mechanized mining face and stage, applied in mining equipment, earthwork drilling, tunnels, etc., to achieve the effect of speeding up the advance speed, reducing the cleaning time, and speeding up the retraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

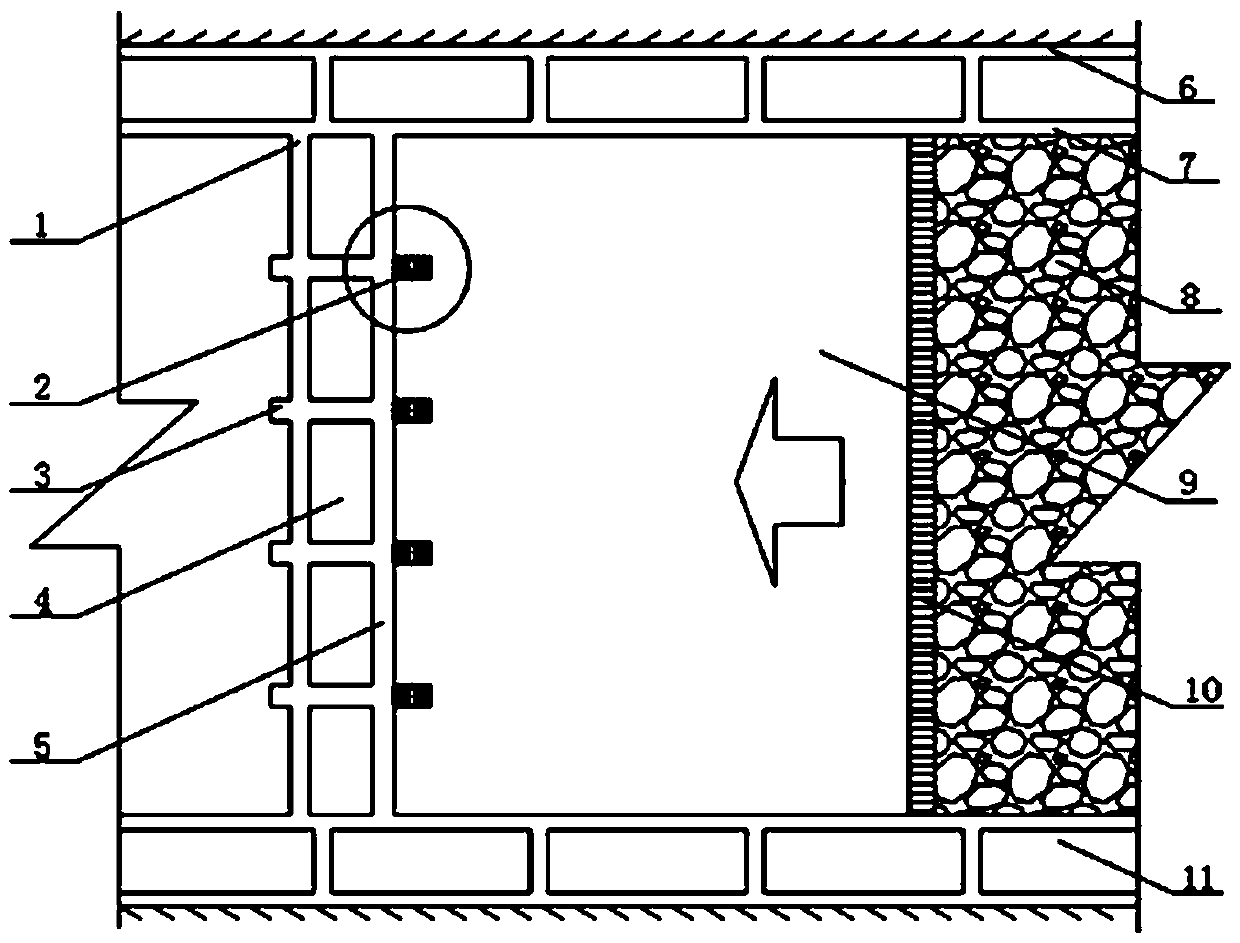

[0025] The present invention will be further described in conjunction with the accompanying drawings.

[0026] A method for preventing excessive deformation of an adjustment roadway in the retraction stage of a fully mechanized mining face, comprising the following steps:

[0027] 1. After the excavation of the withdrawal channel is completed, excavate the adjustment lane 2 in the main side of the main withdrawal channel 5 according to the specific requirements of the withdrawal. The length of the adjustment lane 2 is generally 10-20m, and the width is generally 2.0-5.0m.

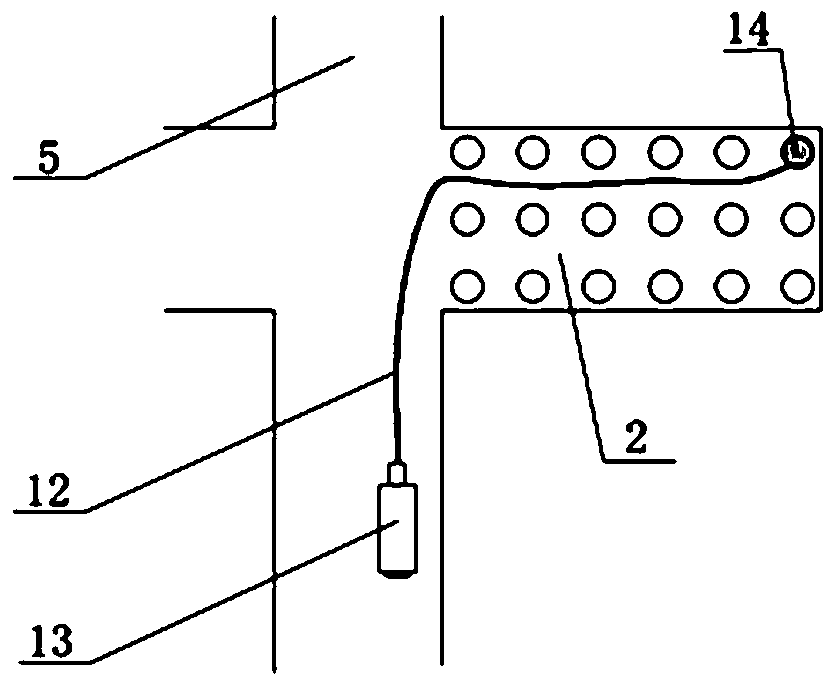

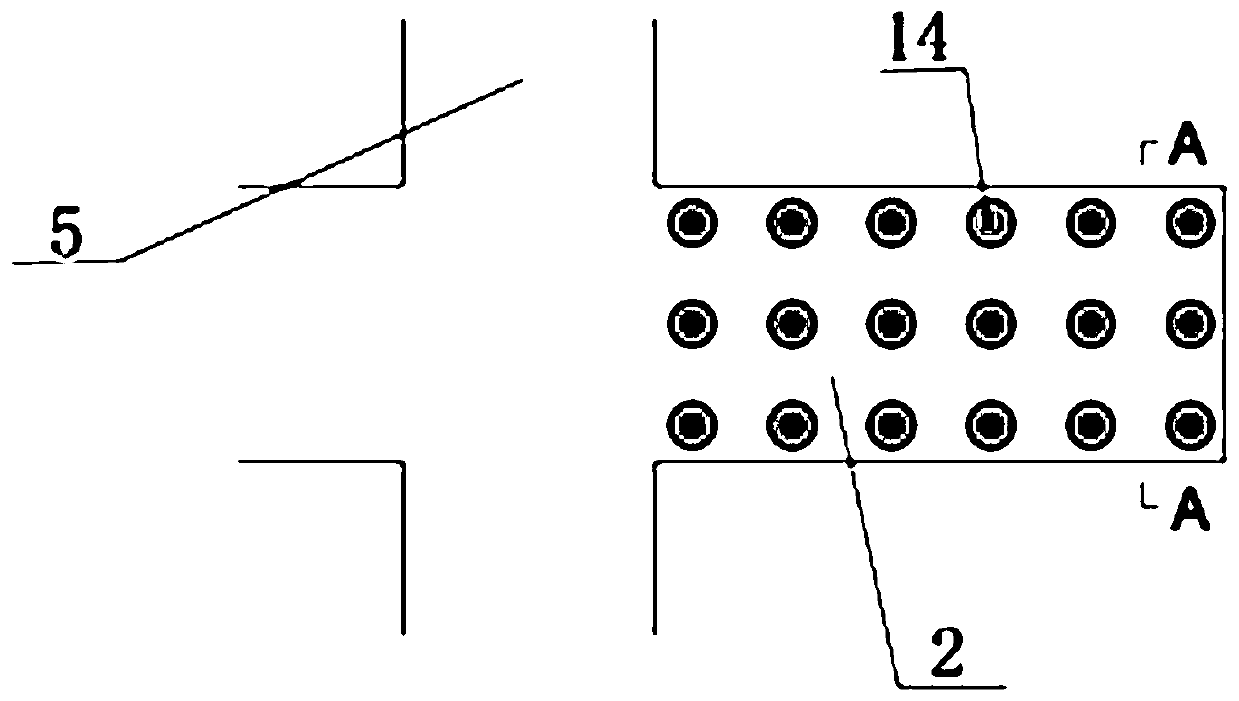

[0028] 2. After the excavation of the adjustment lane 2 is completed, the traditional fiberglass anchors and anchor cables are used for support. After the support is completed, the mold for the support pile 14 is hung from the innermost corner of the adjustment lane 2. The mold is made of nylon braided material The bottom surface is cylindrical with a diameter of 0.8 ~ 1.0m. The interior is pulled by glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com