Underground cavern excavation support system and construction method

An underground cavern and system technology, applied in underground caverns, earthwork drilling, wellbore lining, etc., can solve the problems of stress release and deformation, backward drainage system, rough drainage operation, etc., and achieve stable and improved mechanical properties. The effect of supporting speed and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

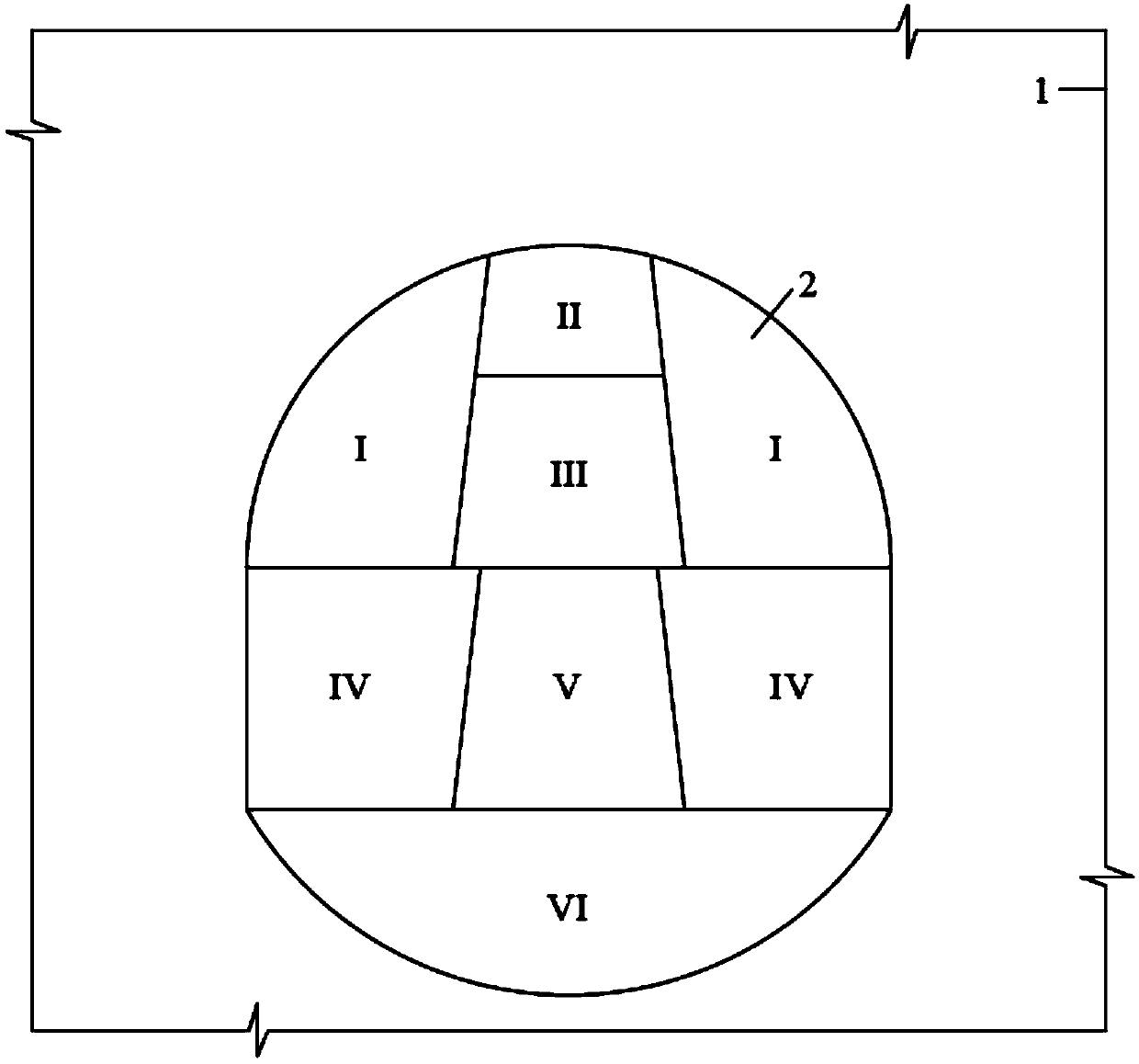

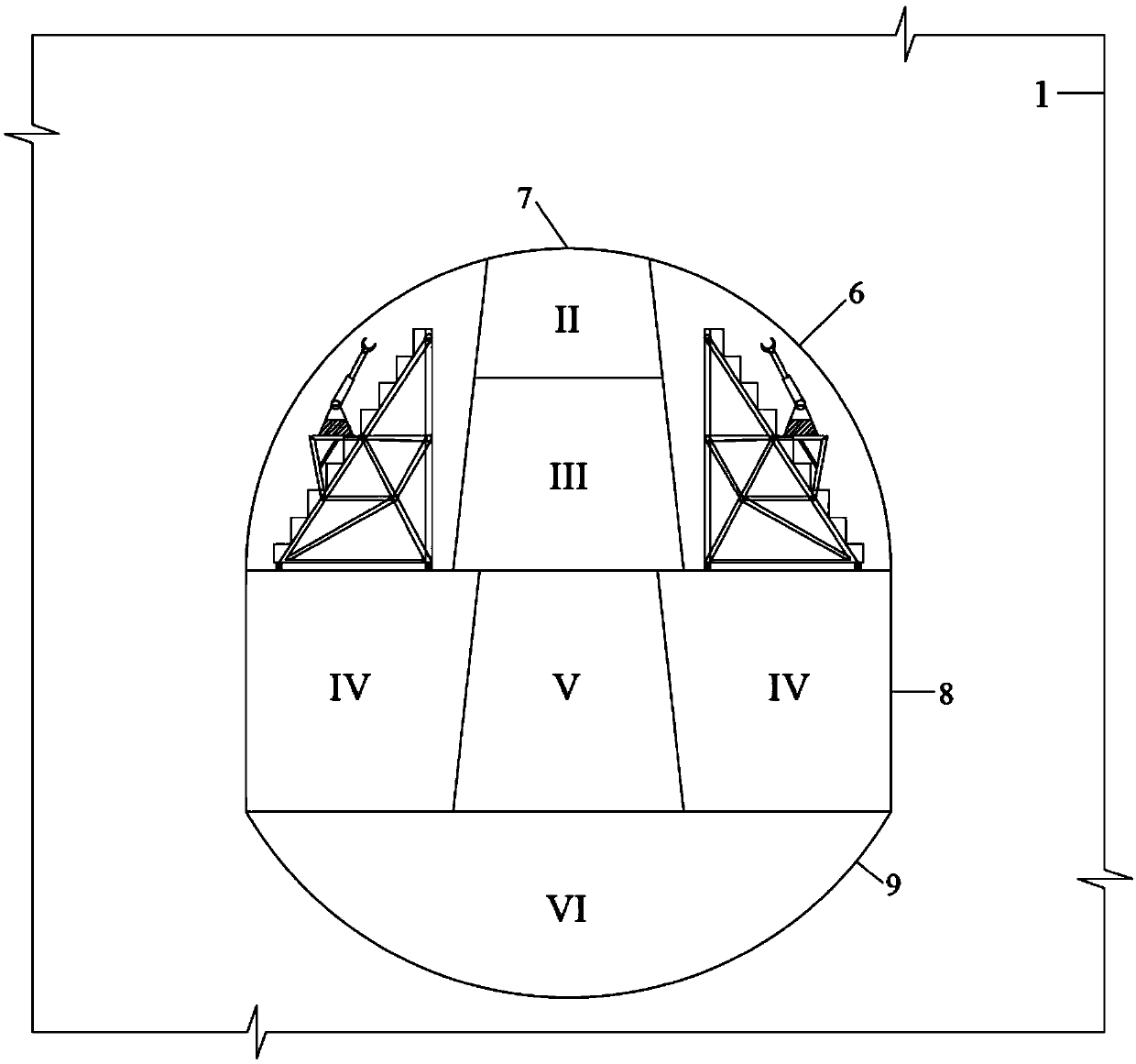

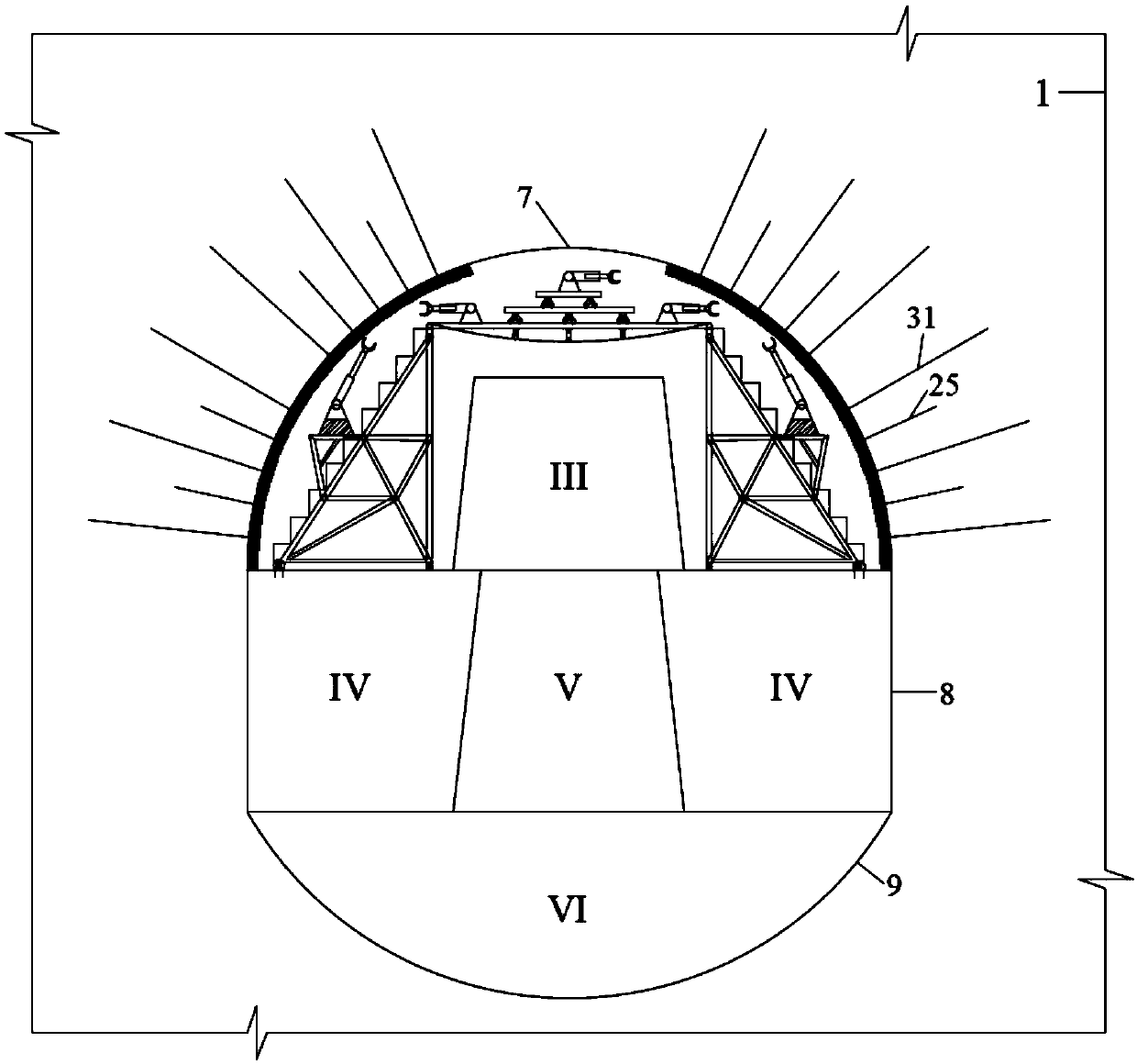

[0043] refer to figure 1 and Figure 8 , the underground cavern 2 is divided into three areas and six blocks, the upper area is the top arch excavation area 3, the middle area is the end wall excavation area 4, the lower area is the inverted arch excavation area 5, and the top arch excavation area is 2 It is the symmetrical block I on both sides, the upper block II in the middle part, and the lower block III in the middle part. The excavation area 4 of the end wall is divided into the block IV symmetrical on both sides and the block V in the middle part. The excavation area 5 of the inverted arch is the block VI. , the excavation areas of blocks I and IV have a certain slope stability angle, which can ensure the geometric stability of the excavation areas of each block.

[0044]Underground cavern excavation support system, including top-down top arch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com