Ventilation and dust removal equipment for coal mine operations

A dust removal equipment and operation technology, which is applied in the ventilation of mines/tunnels, mining equipment, dust prevention, etc., can solve the problems of short service life of ventilation and dust removal equipment, troublesome cleaning, etc., and achieve the effect of improving dust removal effect and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

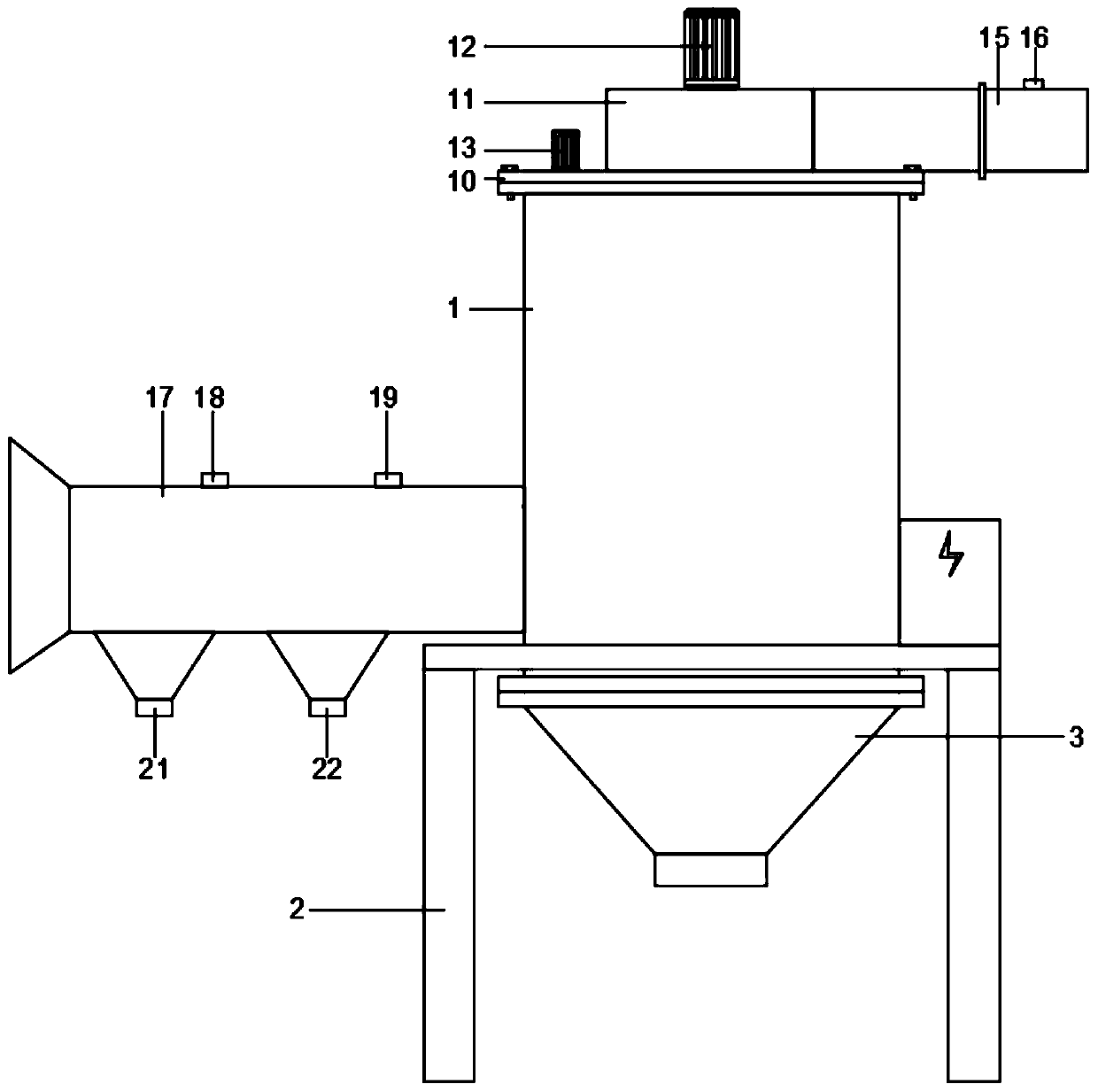

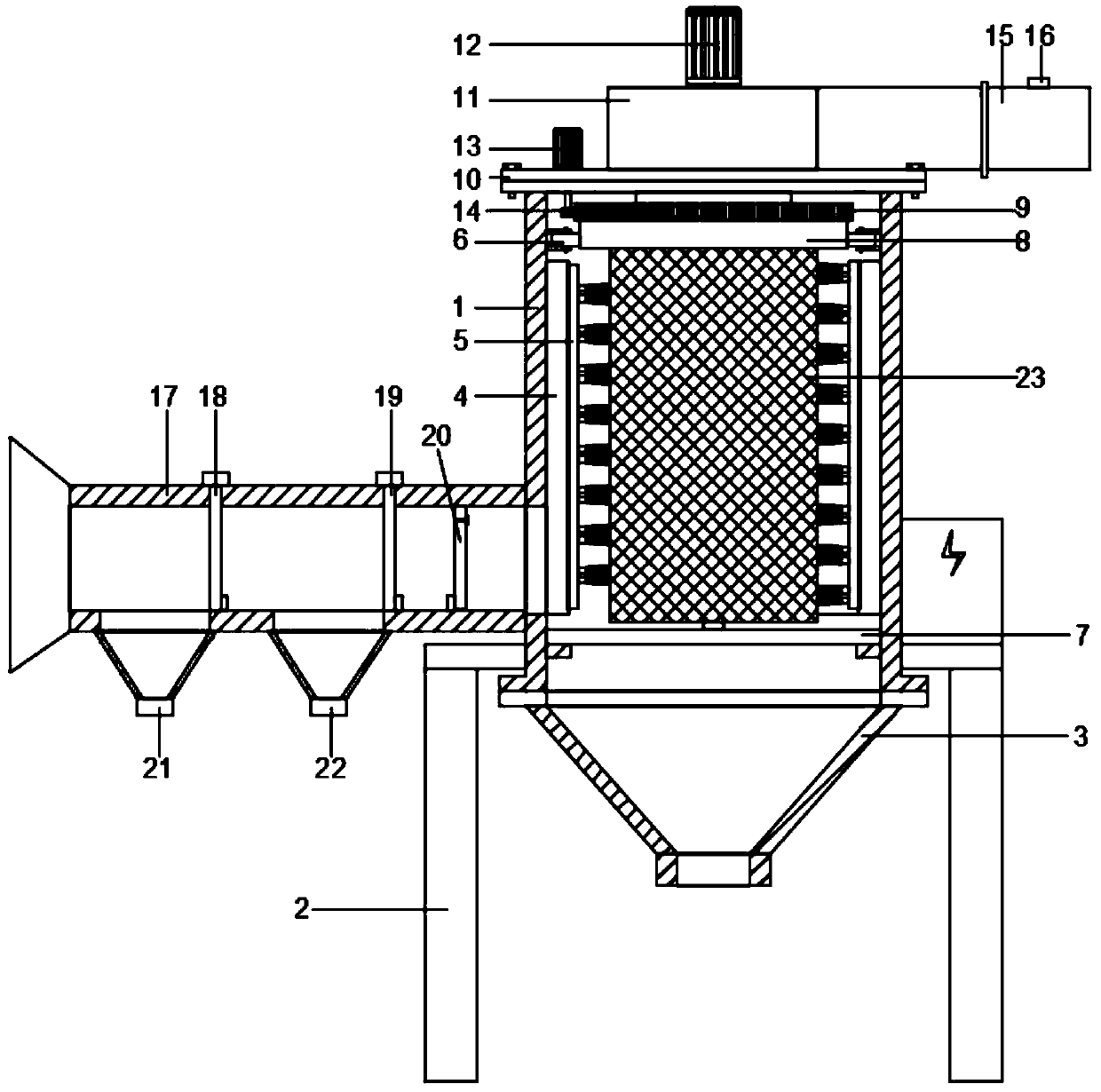

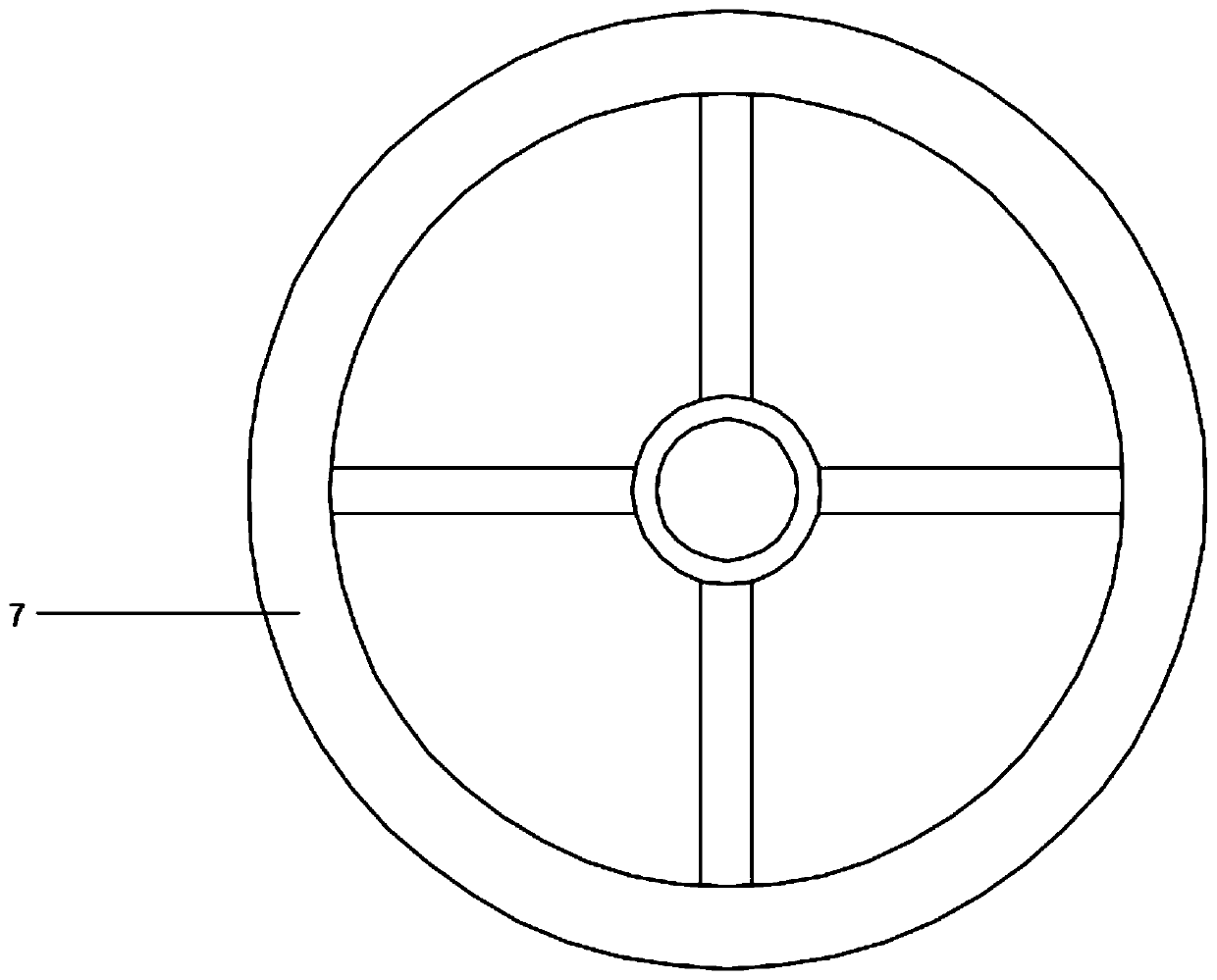

[0038] as attached figure 1 To attach Figure 10 Shown:

[0039]The present invention provides ventilation and dust removal equipment for coal mine operations, including: a dust collection tube 1, a ring 101, a support frame 2, a dust collection bucket 3, a sliding seat 4, a dust removal brush 5, a roller 6, a rotating connection seat 7, a collection Dust cylinder main body 8, circular hole A801, gear ring 9, cover plate 10, centrifugal fan 11, motor A12, motor B13, gear 14, air outlet pipe 15, filter box 16, air inlet pipe 17, first filter plate 18, Circular hole B1801, second filter plate 19, circular hole C1901, one-way valve 20, first collecting hopper 21, second collecting hopper 22 and dust bag 23; the position below the outer wall of dust collecting tube 1 is welded with support frame 2 , and the bottom surface of the dust collection tube 1 is fixedly connected with a dust collection bucket 3 by bolts; the inner wall of the dust collection tube 1 is welded with four s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com