LED strip lens and LED strip lamp with even luminosity of 180 degrees

A technology of LED strip light and LED lens, which is applied to the semiconductor device of light-emitting element, light source, light source fixation, etc., to prevent water vapor from entering, improve sealing, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

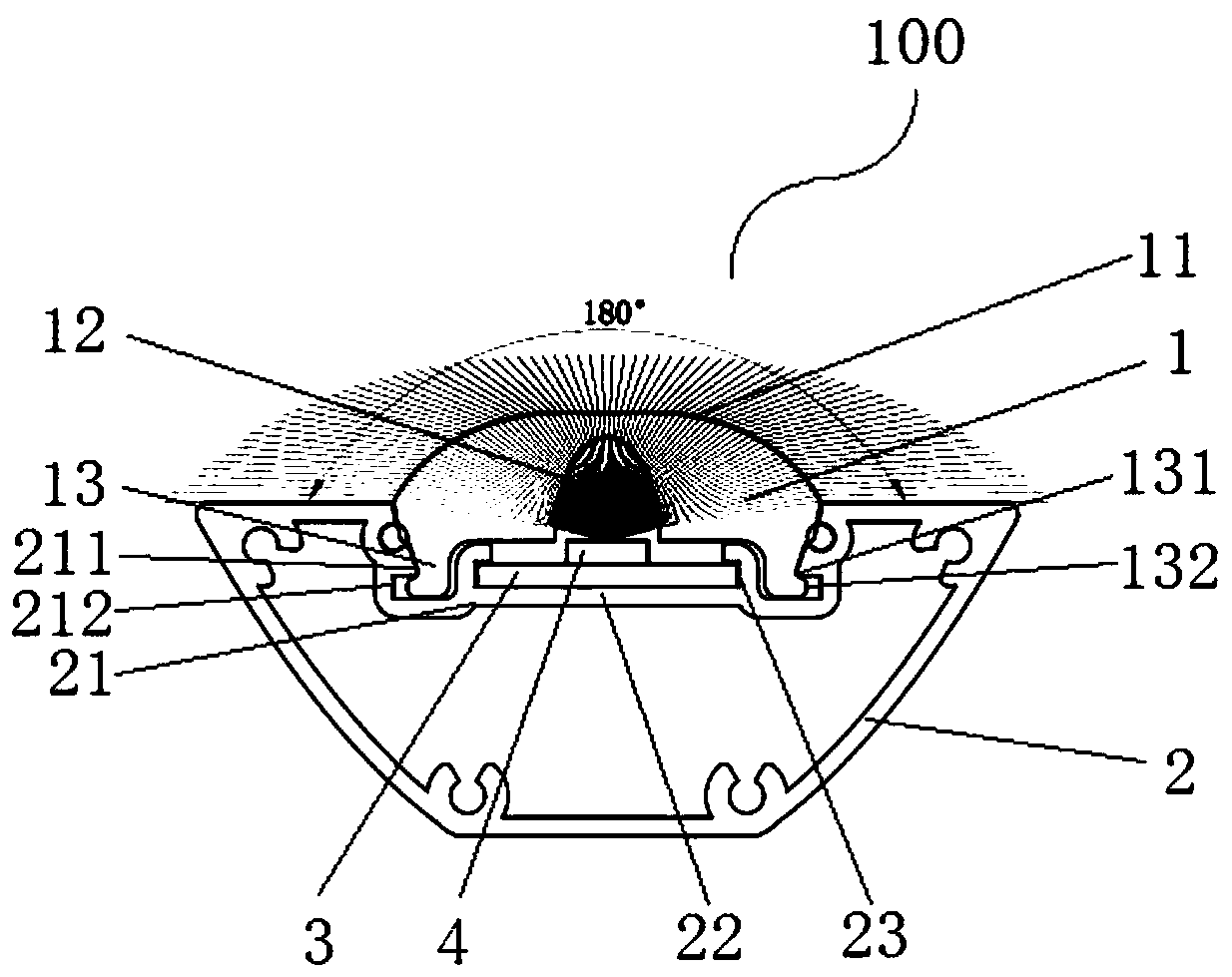

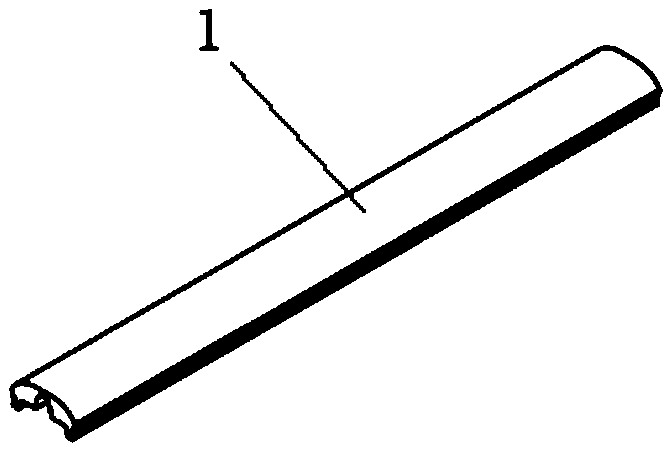

[0024] like figure 1 , 2-1 As shown in 2-5, this embodiment provides a 180-degree uniform LED strip lens 1, the upper surface of the LED strip lens 1 includes two curved curved surfaces 11 that are symmetrical to each other, and the LED strip A semi-elliptical groove 12 is provided in the middle of the lower surface of the LED strip lens 1 , and engaging portions 13 are provided at both sides of the LED strip lens 1 .

[0025] In this embodiment, the structure of the LED strip lens is as follows: first engaging grooves 131 and first protrusions 132 are provided outside the engaging portions 13 at both ends of the LED strip lens 1 .

[0026] This embodiment also provides a 180-degree uniform LED strip light 100, including an LED lens mount 2, the LED lens mount 2 is fitted with the aforementioned LED strip lens 1, and the LED lens mount 2 2 is provided with a fixing seat 21 that engages with the engaging portion 13 of the LED strip lens 1 .

[0027] In this embodiment, the s...

Embodiment 2

[0031] like image 3 , 4 As shown, this embodiment provides another LED strip lens 1 with uniform luminosity of 180 degrees. The upper surface of the LED strip lens 1 includes two curved curved surfaces 11 that are symmetrical to each other. The LED strip lens 1 A semi-elliptical groove 12 is provided in the middle of the lower surface of the LED strip lens 1 , and engaging parts 13 are provided at both sides of the LED strip lens 1 .

[0032] In this embodiment, the structure of the LED strip lens 1 is as follows: a second engaging groove 133 is provided on the outside of the engaging portion 13 at both ends of the LED strip lens 1, and the engaging portion 13 and the LED strip lens 1. The LED lens bar seat 10 arranged below is integrally formed.

[0033] In the structure of the LED strip lens 1 of this embodiment, the second protrusions 134 are provided inside the engaging parts 13 at both ends of the LED strip lens 1, and the second protrusions 134 on both sides are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com