Method for determining fatigue test load of engine main shaft

A technique for fatigue testing and determination of methods, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problems that the spindle fatigue test can only be carried out on a special shaft fatigue tester, and achieve improvement The effect of load loading accuracy, reducing loading difficulty and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

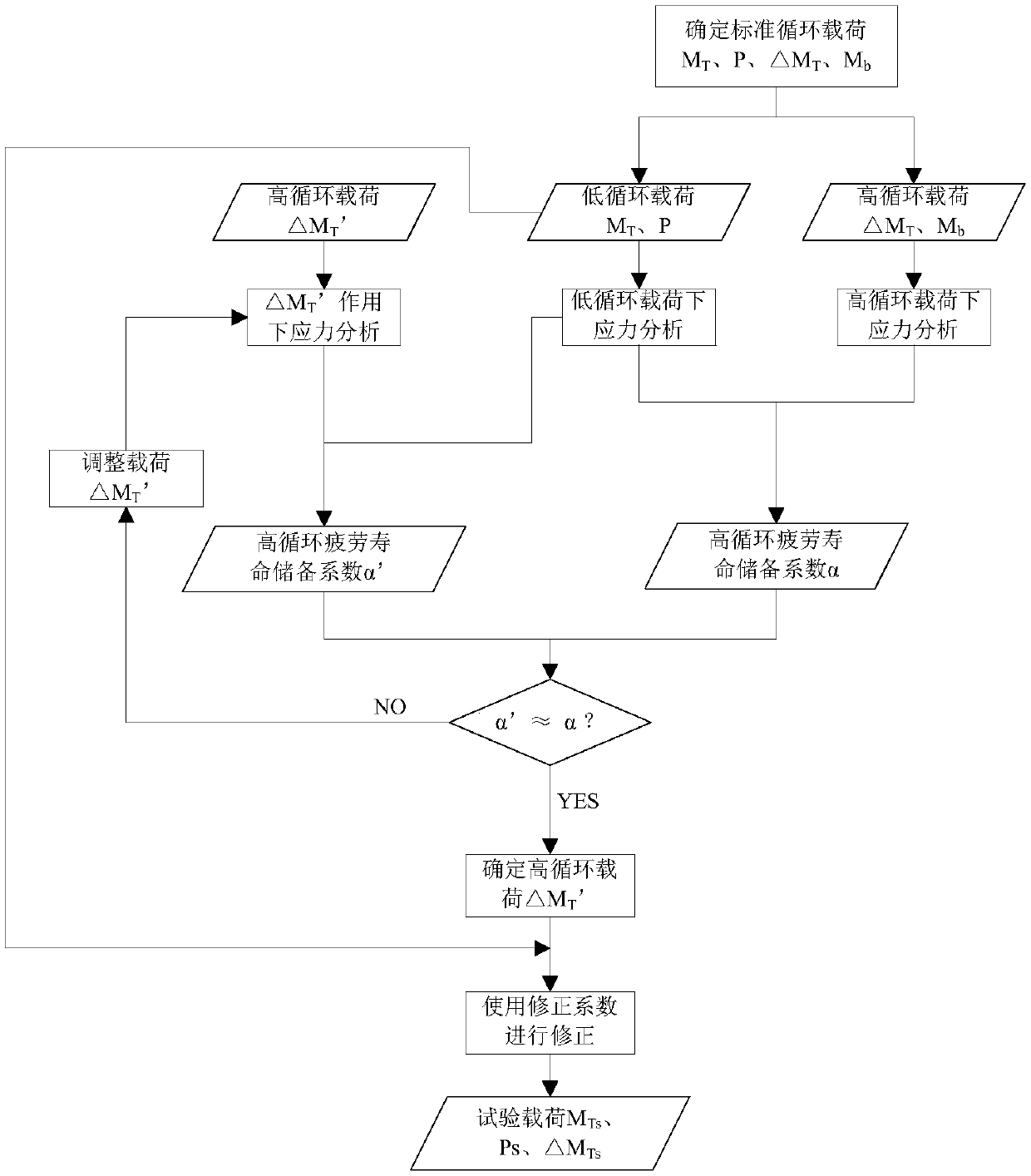

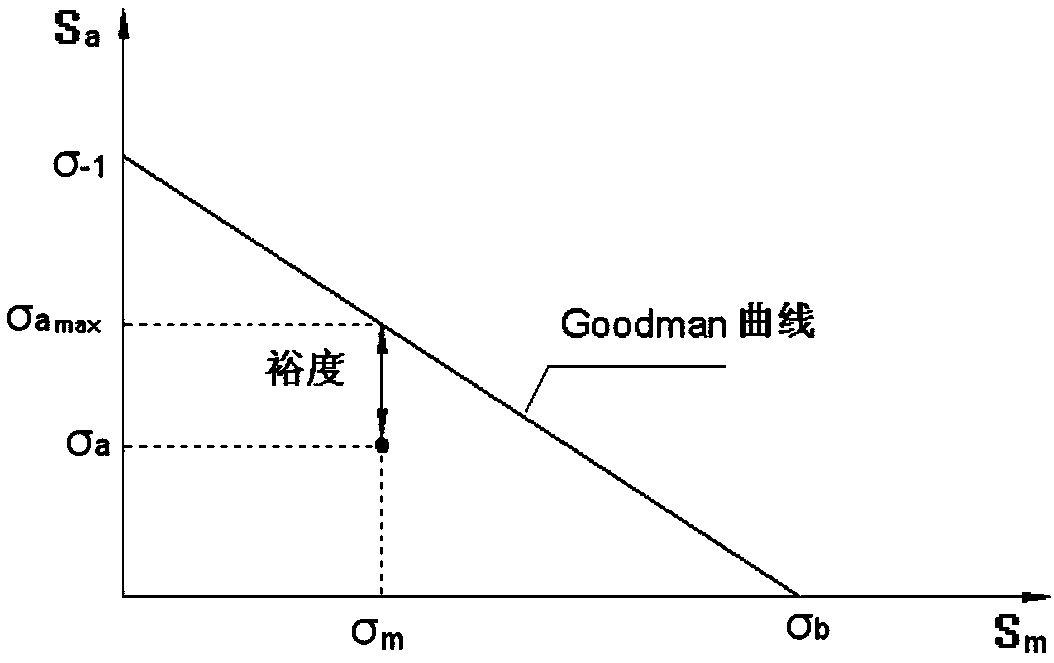

[0030] The invention of the present invention is optimized and improved on the basis of determining the test load by the original life divergence coefficient method. After determining the standard cyclic load of the main shaft, the standard cyclic load is converted into an equivalent cyclic load by adding an equivalent conversion of the load, and then multiplied by With the corresponding divergence coefficient, the test load spectrum is obtained. Taking the axial flow engine as an example, its technical scheme and specific implementation are introduced.

[0031] The specific process for determining the fatigue test load of the engine main shaft is as follows: figure 1 shown.

[0032] (1) Determine the standard cyclic load

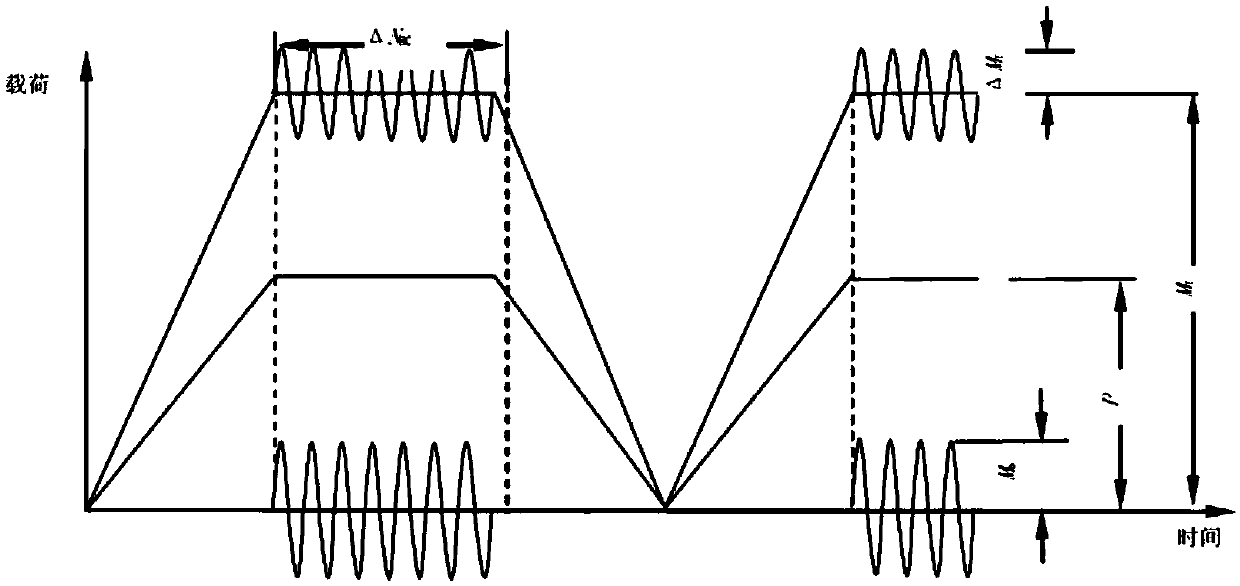

[0033] The load that affects the fatigue life of the spindle is mainly the torque M T , vibration torque ΔM T , axial force P, rotational bending moment M b , these loads of the main shaft life assessment part constitute the standard cyclic load of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com