Gas phase chromatography carrier gas switching use method

A gas chromatography and carrier gas technology, applied in the field of gas chromatography carrier gas switching, can solve the problems of low switching efficiency, inflexibility, inconvenient carrier gas switching, etc., and achieve the effects of cost saving, large expansion range and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

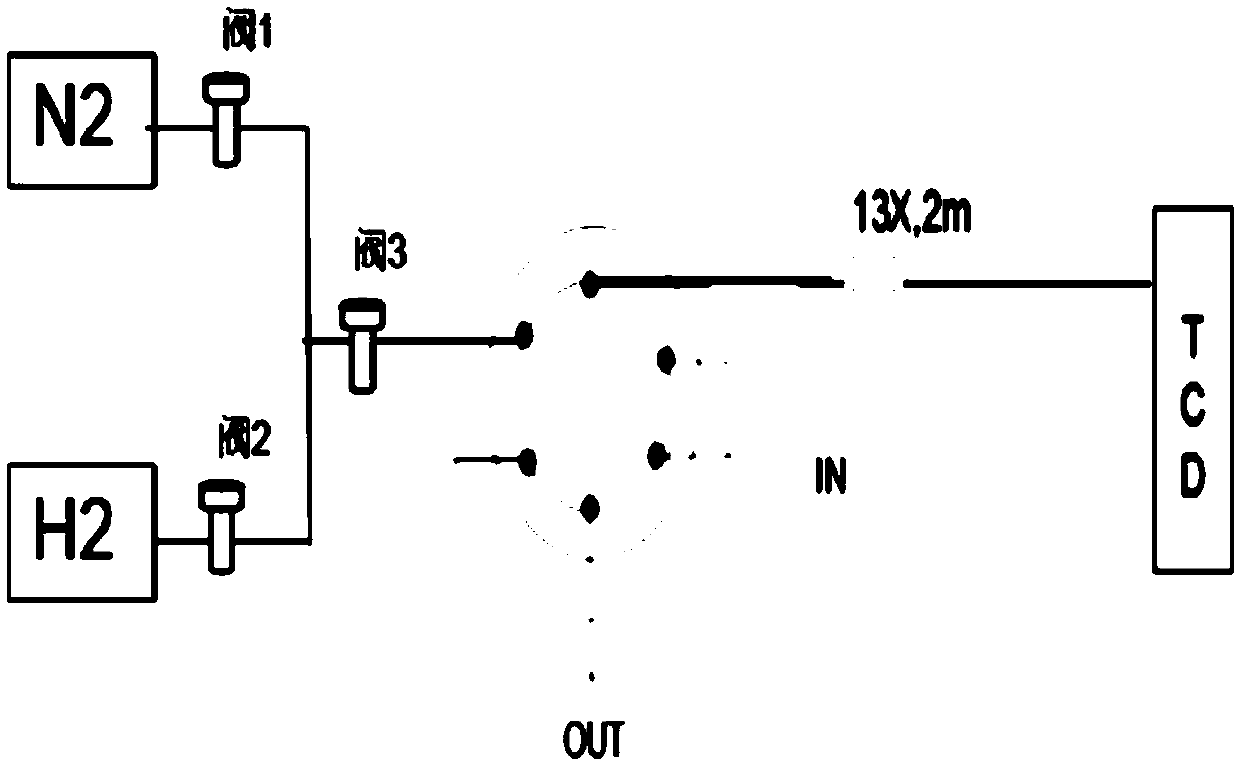

[0021] see Figure 1-3 , a gas chromatographic carrier gas switching method, characterized in that the gas path transformation is carried out, and the carrier gas switching technology is used to realize the analysis of different gases in a single gas path, and the switching of the carrier gas is realized by switching the valve. 2 When gas is the carrier gas, H 2 detection, when H 2 When the gas is the carrier gas, O 2 (AR), N 2 、CH 4 , CO detection.

[0022] The detector used is a TCD detector, the chromatographic column used is a 13-X chromatographic column, the temperature of the column oven is 62°C, the detector temperature is 155°C, and the detector current is 84mA.

Embodiment 2

[0024] see Figure 1-3 , a gas chromatographic carrier gas switching method, characterized in that the gas path transformation is carried out, and the carrier gas switching technology is used to realize the analysis of different gases in a single gas path, and the switching of the carrier gas is realized by switching the valve. 2 When gas is the carrier gas, H 2 detection, when H 2 When the gas is the carrier gas, O 2 (AR), N 2 、CH 4 , CO detection.

[0025] The detector used is a TCD detector, the chromatographic column used is a 13-X chromatographic column, the temperature of the column oven is 60°C, the detector temperature is 165°C, and the detector current is 85mA.

Embodiment 3

[0027] see Figure 1-3 , a gas chromatographic carrier gas switching method, characterized in that the gas path transformation is carried out, and the carrier gas switching technology is used to realize the analysis of different gases in a single gas path, and the switching of the carrier gas is realized by switching the valve. 2 When gas is the carrier gas, H 2 detection, when H 2 When the gas is the carrier gas, O 2 (AR), N 2 、CH 4 , CO detection.

[0028] The detector used is a TCD detector, the chromatographic column used is a 13-X chromatographic column, the temperature of the column oven is 60°C, the detector temperature is 155°C, and the detector current is 82mA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com