A component automatic assembly device

An automatic assembly device and automatic assembly technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problem of low economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

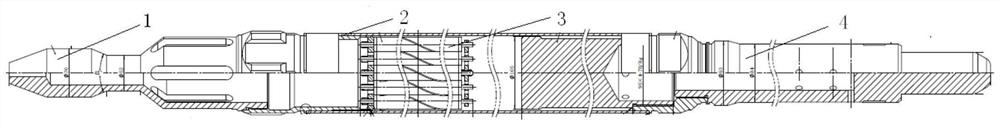

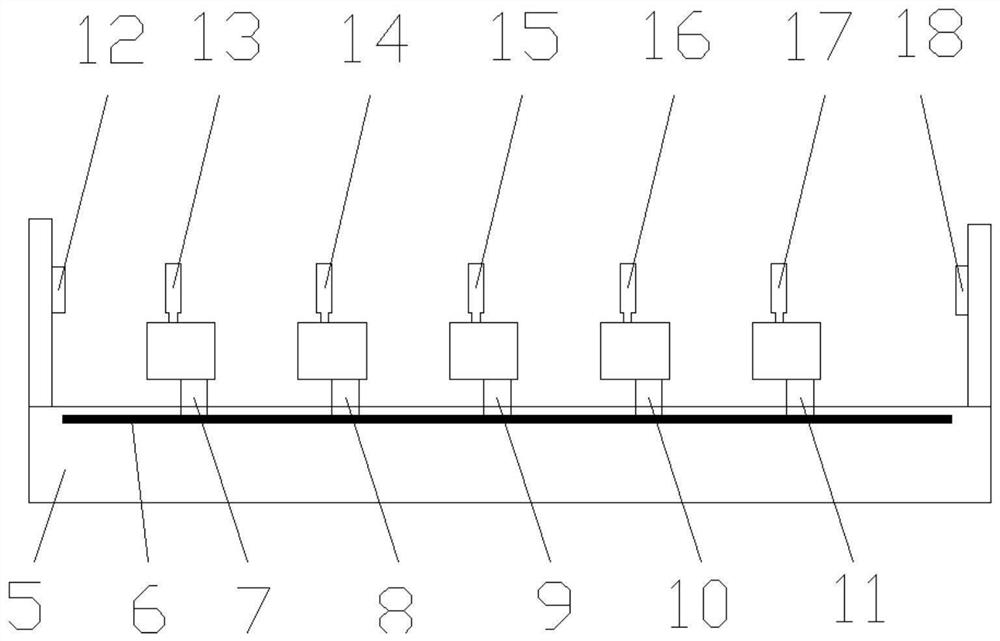

[0019] Component structure see figure 1 , The assembly consists of an upper operating head 1, an outer casing 2, a rod bundle 3, and a lower secondary component 4. The structure of the component automatic assembly device is shown in figure 2 , consisting of equipment bed 5, rack 6, motor a7, motor b8, motor c9, motor d10, motor e11, force sensor a12, jaw a13, jaw b14, jaw c15, jaw d16, jaw e17, The force sensor b18 is composed. The equipment bed 5 is placed horizontally, and the rack 6 whose length is equal to the equipment bed 5 is installed above the equipment bed 5 . Jaw a13 , jaw b14 , jaw c15 , jaw d16 , jaw e17 are connected to rack 6 through motor a7 , motor b8 , motor c9 , motor d10 and motor e11 respectively. The output ends of motor a7, motor b8, motor c9, motor d10, and motor e11 are gears meshing with rack 6, and the motors r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com