Design and processing method of aluminum alloy hanger forging for high-speed car plug door

A technology for car plug sliding doors and processing methods, which is applied in metal processing equipment, mechanical equipment, engine components, etc., can solve the problems of unstable process parameters, poor production environment, high cost, and achieve rich reserves, high production efficiency, high low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the design and processing method of aluminum alloy hanger forgings for high-speed car plug doors, the specific steps are as follows:

[0038] (1) Adopt 6061 deformed aluminum alloy;

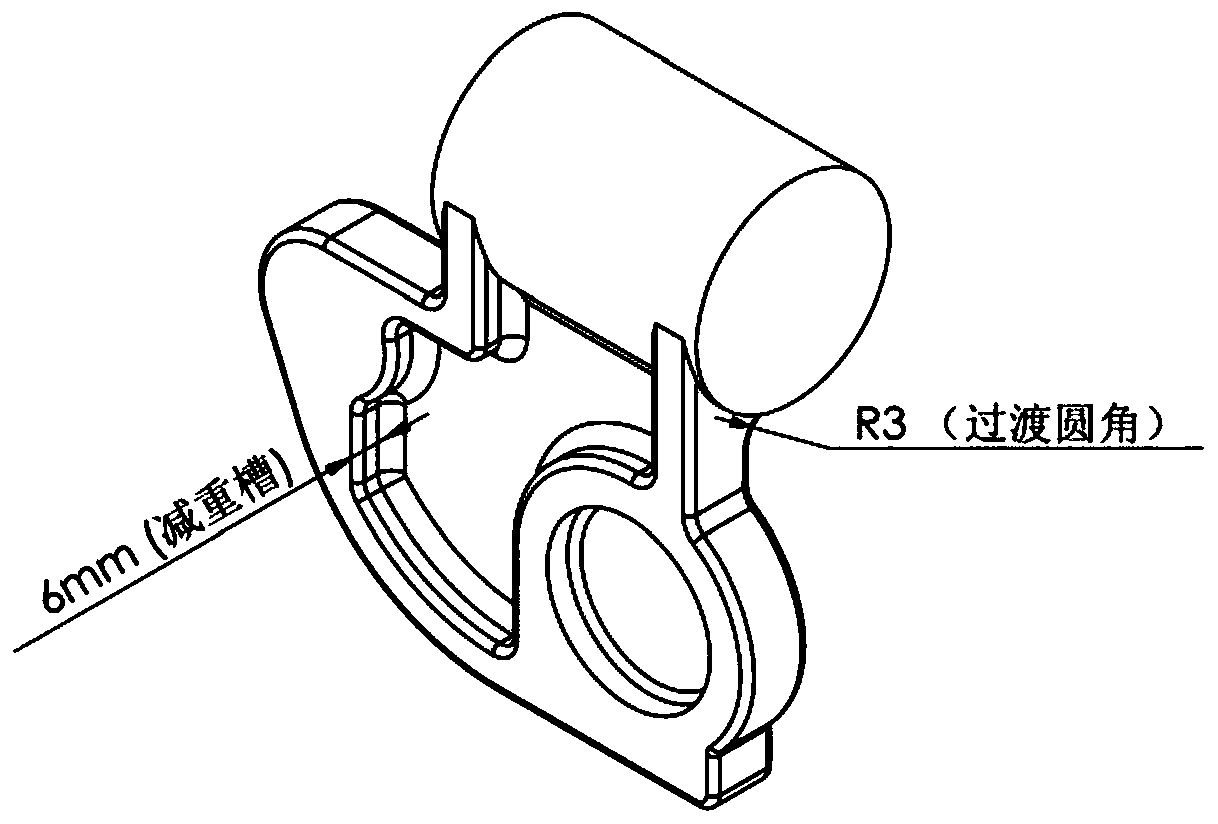

[0039] (2) if figure 1 As shown, the optimal design of forging structure:

[0040] 1) Improve the design on the basis of the original casting structure, omit the corresponding structures such as the pouring system, simplify the shape, and be suitable for forging;

[0041] 2) Design a weight-reducing groove on the non-stressed plane, avoiding the matching hole, and the depth is 6mm;

[0042] 3) Design transitional rounded corners around the outline, with a radius of 3mm, which is easy to forge and reduce stress concentration;

[0043] (3) Free forging billet:

[0044] 1) The size of the forging billet is intercepted to Φ150mm×100mm, and surface defects, flashes, debris, etc. are removed. Before forging, the anvil contacting the billet is preheated to 250°C. The surfa...

Embodiment 2

[0059] In this embodiment, the design and processing method of aluminum alloy hanger forgings for high-speed car plug doors, the specific steps are as follows:

[0060] (1) 2A14 deformed aluminum alloy is used;

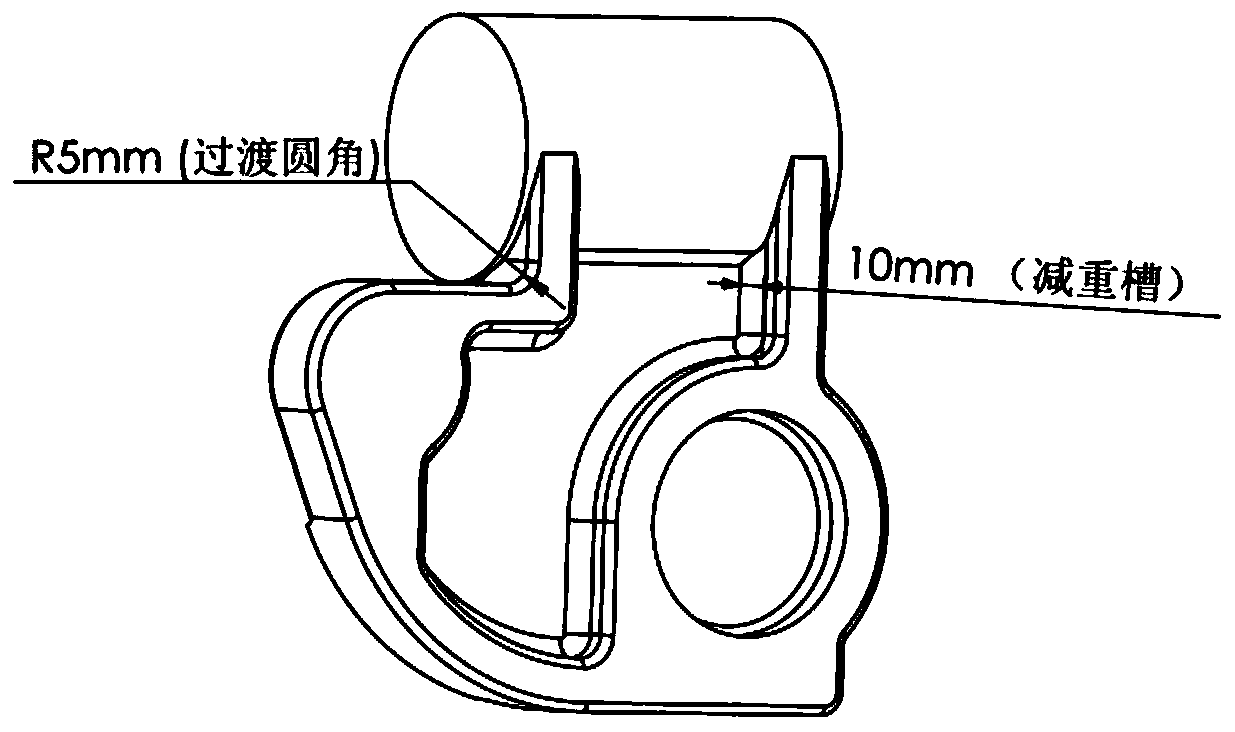

[0061] (2) if figure 2 As shown, the optimal design of forging structure:

[0062] 1) Improve the design on the basis of the original casting structure, omit the corresponding structures such as the pouring system, simplify the shape, and be suitable for forging;

[0063] 2) Design a weight-reducing groove on the non-stressed plane, avoiding the matching hole, and the depth is 10mm;

[0064] 3) Design transitional rounded corners around the outline, with a radius of 5mm, which is easy to forge and reduce stress concentration;

[0065] (3) Extrusion billet:

[0066] 1) The size of the billet is Φ150mm×200mm, remove oil stains, and preheat to 350°C in a box-type resistance furnace;

[0067] 2) The extrusion temperature is 400°C, and the extrusion speed is 3-4mm / s; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com