A short-process gold extraction method for alkaline sulfur-arsenic-coated gold deposits

An encapsulated, short-flow technology, applied in the field of short-flow gold extraction from alkaline sulfur-arsenic encapsulated gold mines, can solve the problems of reducing the content of acid-consuming carbonate minerals, poor permeability, and low oxidation efficiency, and achieves The effect of ensuring the permeability characteristics, improving the fine porosity, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

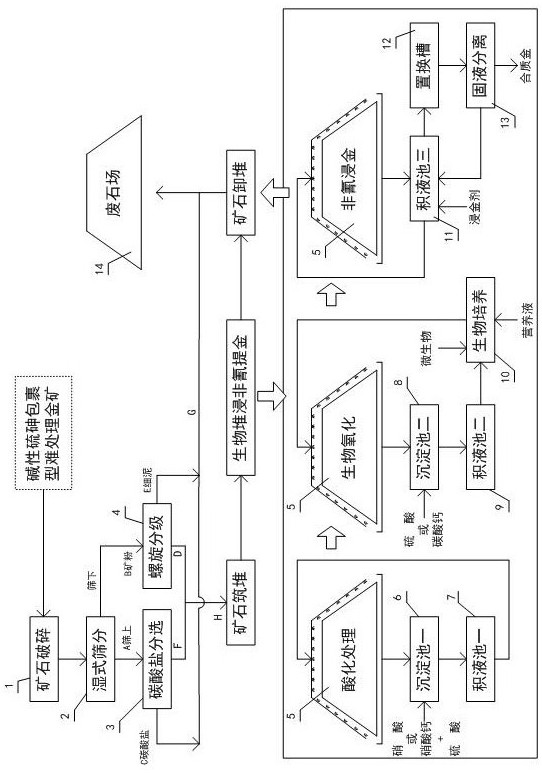

[0025] Such as figure 1 As shown, the present invention discloses a short-process gold extraction method for alkaline sulfur-arsenic-encased gold ore. First, the ore is mined according to the existing method and sent to the crushing equipment 1. In the crushing process, the ore is crushed to a predetermined particle size, usually within 0--50mm; the crushed ore is transported to the screening equipment 2 for spray wet screening, the primary wet screening obtains coarse-grained ore A and fine ore B, and the coarse-grained ore A on the screen enters the carbonate Selecting equipment 3, the fine ore B under the sieve enters the hydraulic spiral grading or secondary wet screening equipment, and the hydraulic spiral grading equipment 4 is selected in this embodiment. Coarse-grained ore A is sorted by carbonate sorting equipment 3 to obtain large-grained carbonate ore C and large-grained ore F; ore powder B is classified and screened by hydraulic spiral to obtain coarse-grained mine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com