Ozone micro-bubble generator for degrading pesticides and preparation method therefor

A micro-bubble generator, a technology for degrading pesticides, applied in chemical instruments and methods, dissolution, application and other directions, can solve problems such as slow reaction rate, save costs, reduce energy consumption, and improve the effect of degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

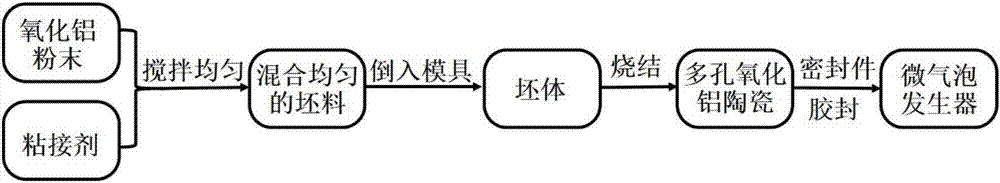

[0032] The preparation flow chart of ozone microbubble generator is as follows: figure 1 .

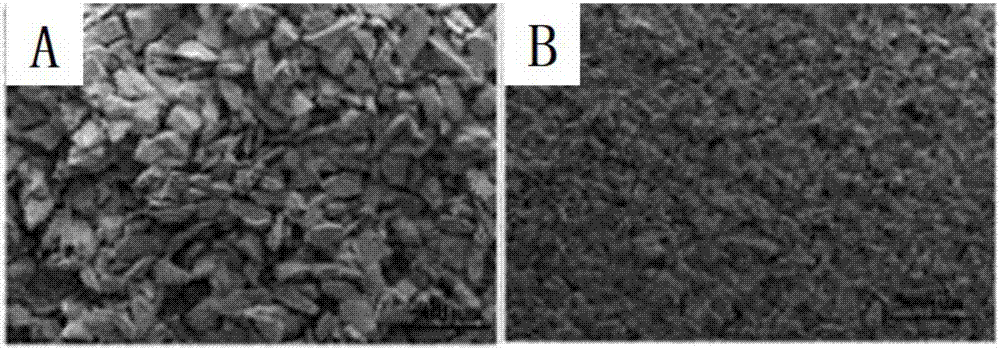

[0033] Take 40g of iron-containing alumina powder with a particle size of 10-20μm in a 100ml beaker, and add 4g of prepared adhesive. Stir to obtain a uniformly mixed billet, pour the billet into a cylindrical mold with a diameter of 65mm and a thickness of 6.5mm, and then press it into a dense green body, put the mold in an oven at 80°C for 1 hour, take it out, open the mold, and the green body Forming, put the formed body into a muffle furnace, raise the temperature to a certain temperature at a rate of 5°C / min, sinter for 1 hour, and naturally cool to obtain the required porous alumina ceramics. The obtained porous alumina ceramics are composed of alumina particles, and the pore size is about 5 μm. Insert the ceramic into the seal and seal it with glue to make a microbubble generator.

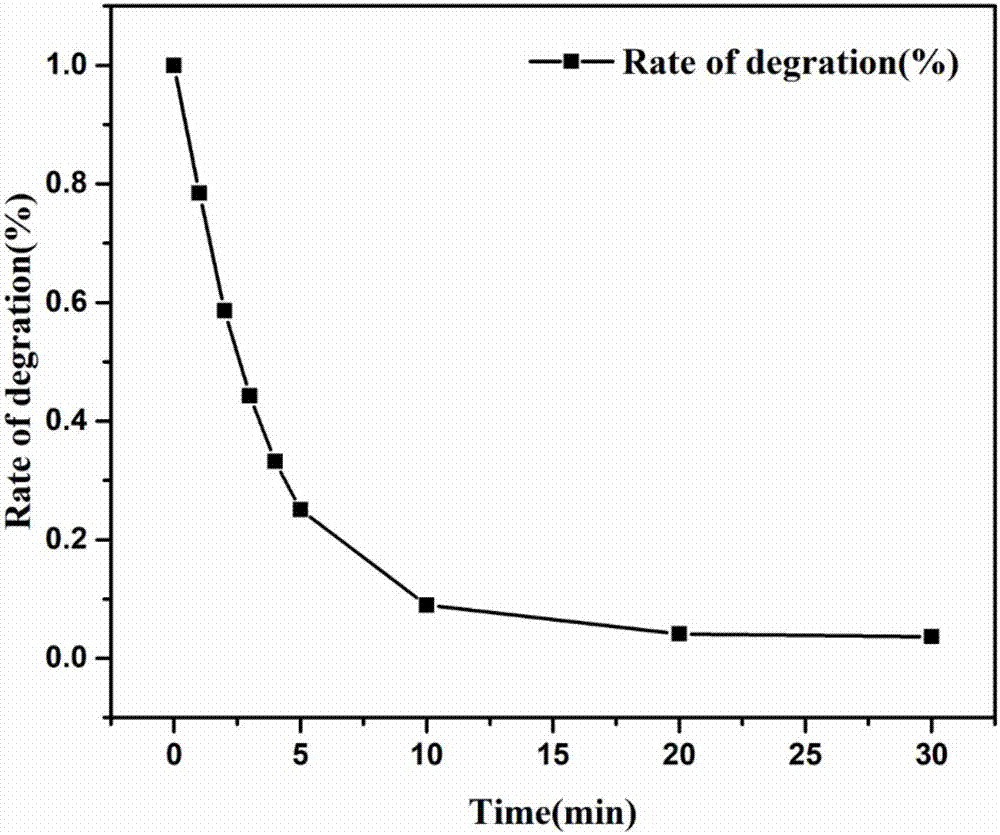

[0034] Connect the microbubble generator to the ozone generator and place it in a 1L beaker, a...

Embodiment 2

[0037] The preparation flow chart of ozone microbubble generator is as follows: figure 1 .

[0038] Take 40g of iron-containing alumina powder with a particle size of 50-60μm in a 100ml beaker, and add 5g of prepared adhesive. Stir to obtain a uniformly mixed billet, pour the billet into a cylindrical mold with a diameter of 65mm and a thickness of 6.5mm, and then press it into a dense green body, put the mold in an oven at 80°C for 2 hours, take it out, open the mold, and the green body Forming, put the formed body into a muffle furnace, raise the temperature to a certain temperature at a rate of 5°C / min, sinter for 1.5h, and naturally cool to obtain the required porous alumina ceramics. Insert the ceramic into the seal and seal it with glue to make a microbubble generator.

[0039] Connect the microbubble generator to the ozone generator and place it in a 1L beaker, add 50mg / L imidacloprid, pass through ozone, and degrade for 0.5h. After testing, the degradation rate of imi...

Embodiment 3

[0042] The preparation flow chart of ozone microbubble generator is as follows: figure 1 .

[0043] Take 42g of iron-containing alumina powder with a particle size of 80-100μm in a 100ml beaker, and add 7g of prepared adhesive. Stir to obtain a uniformly mixed billet, pour the billet into a cylindrical mold with a diameter of 65mm and a thickness of 6.5mm, and then press it into a dense green body, put the mold in an oven at 80°C for 1 hour, take it out, open the mold, and the green body Forming, put the formed body into a muffle furnace, raise the temperature to a certain temperature at a rate of 10°C / min, sinter for 2 hours, and naturally cool to obtain the required porous alumina ceramics. The obtained porous alumina ceramics are composed of alumina particles, and the pore size is about 30 μm. Insert the ceramic into the seal and seal it with glue to make a microbubble generator.

[0044] Connect the microbubble generator to the ozone generator and place it in a 1L beake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com