Metal chuck used for being matched with bolt to achieve high-strength connection

A metal clip and high-strength technology, applied in the direction of connecting components, nuts, threaded fasteners, etc., can solve problems such as insufficient connection strength, achieve high production efficiency, good consistency and stability, and liberate labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

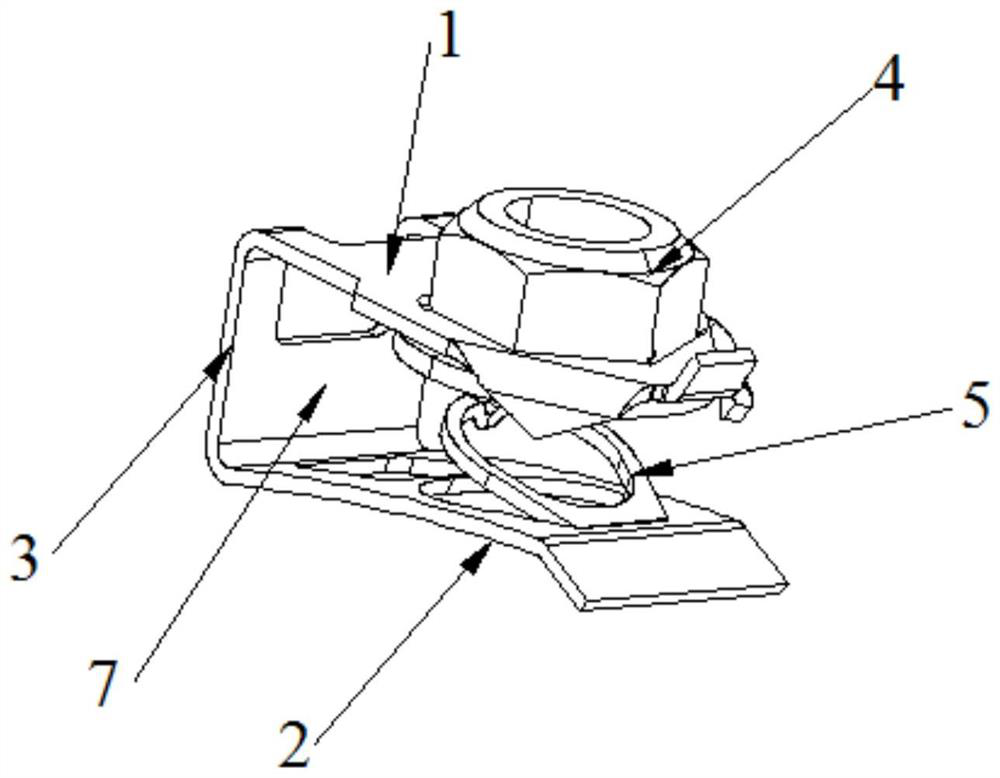

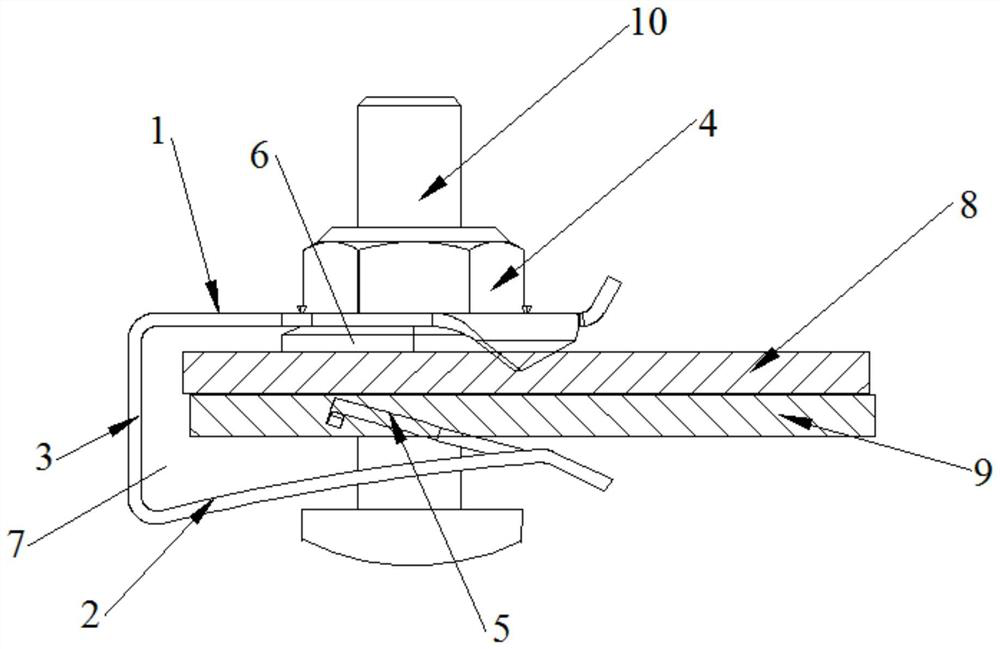

[0037] refer to figure 1 and figure 2 , this embodiment provides a metal collet used to cooperate with bolts to achieve high-strength connection, the metal collet includes a first clamping piece 1, a second clamping piece 2, a connecting piece 3 and a lock nut 4 And the anti-off lock tongue 5, the first clamping piece 1 and the second clamping piece 2 are connected through the connecting piece 3, and the first clamping piece 1 and the second clamping piece 2 are formed for Clamp the card groove 7 of the first plate to be connected 8 and the second plate to be connected 9, the lock nut 4 is connected above the first clamping piece 1, and is used to lock and pass through the second clamping piece 2. The second plate to be connected 9, the first plate to be connected 8 and the bolt 10 of the first clamping piece 1 to realize the first plate to be connected 8 with through holes and the second plate to be connected with through holes 9, the anti-off locking tongue 5 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com