Continuous punching structure for printing

A hole structure and hole matching technology, which is applied in metal processing and other directions, can solve the problems of elongated round holes, low production efficiency, low punching quality, and low punching quality, and achieves small shape contact surface, good punching effect, High-quality punching results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

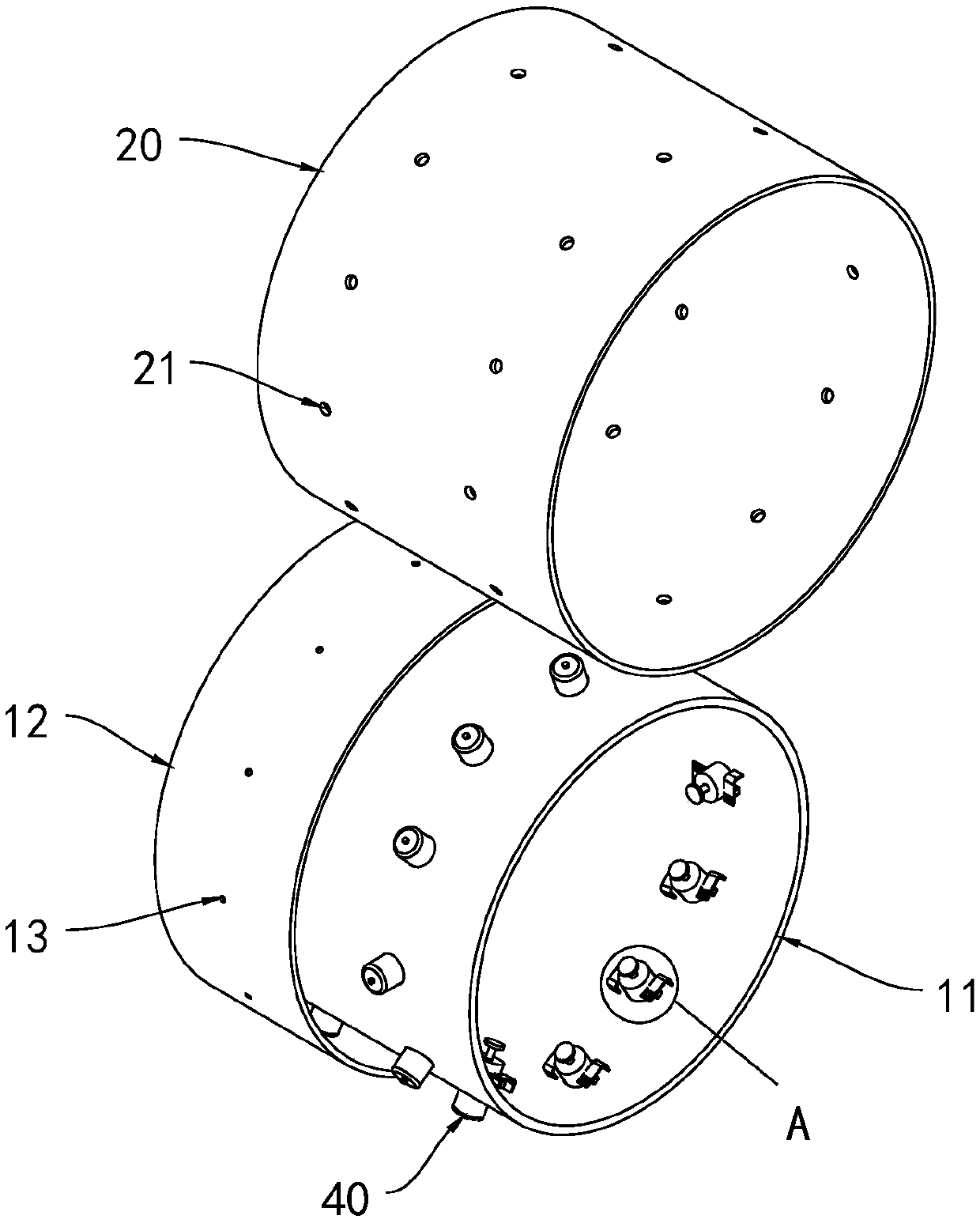

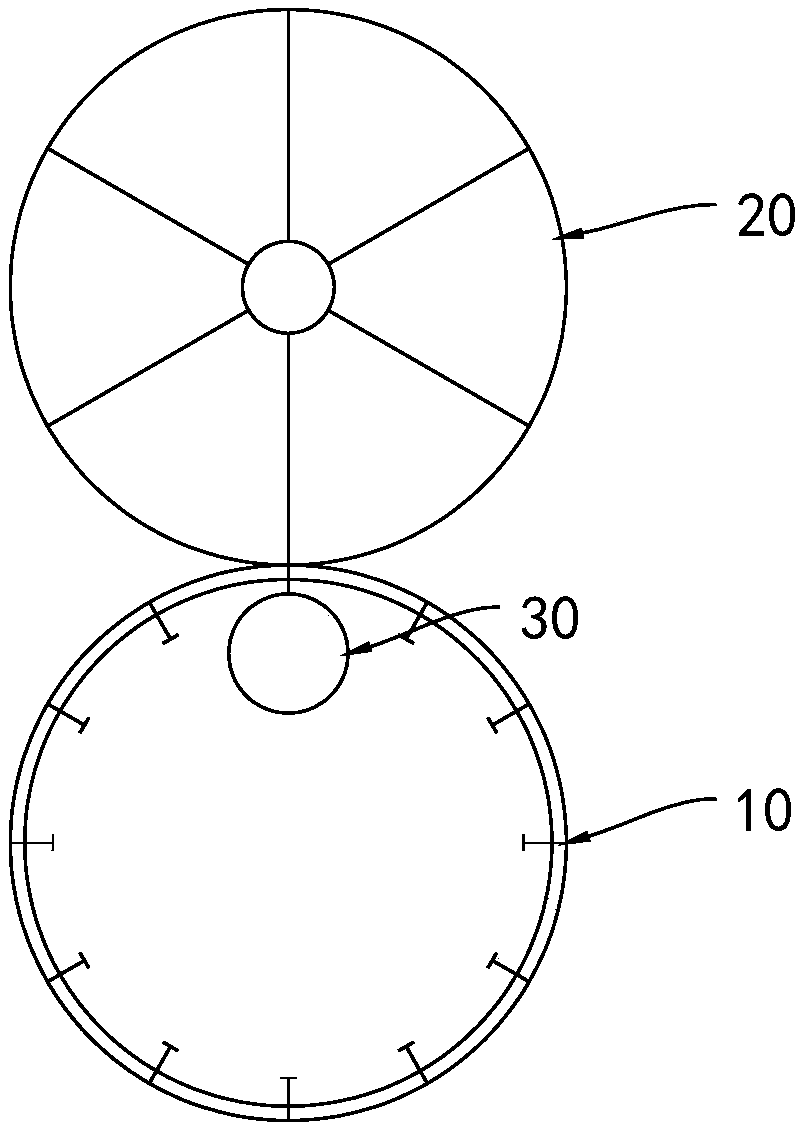

[0022] Embodiment: continuous perforation structure for printing, including a circumscribed perforated cylinder 10 and a perforated cylinder 20; the perforated cylinder 10 includes a coaxial inner cylinder 11 and an outer cylinder 12, and the outer cylinder 12 is distributed with Circumferential positioning holes 13, the inner cylinder 11 is provided with pegs 40 opposite to the positioning holes 13 and radially moving along the outer cylinder 12, the inner cylinder 11 is provided with eccentric pressure rollers 30, and the pressure rollers 30 and the pegs 40 Matching, and the axes of the outer cylinder 12 , the pressure roller 30 and the hole matching cylinder 20 are located in the same plane;

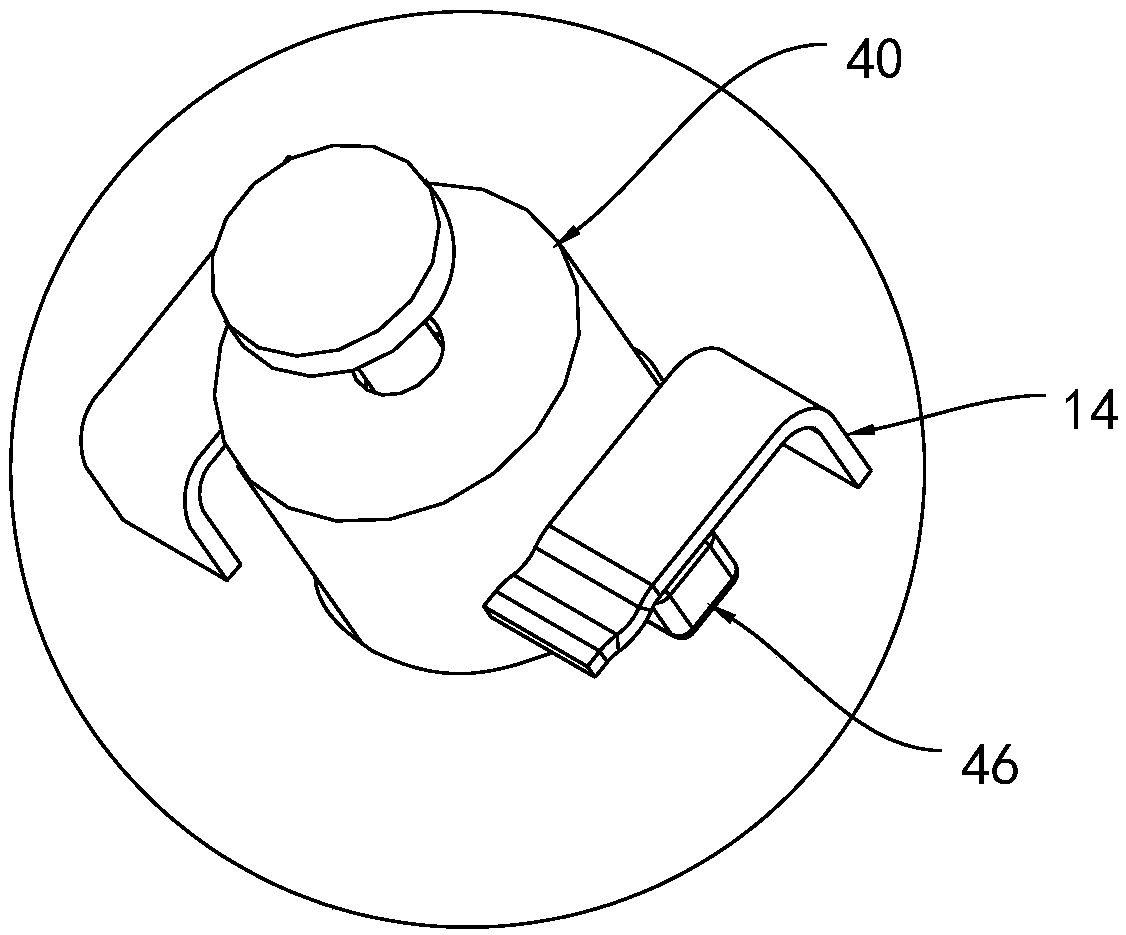

[0023] The end face of the hole pin 40 in contact with the paper has a raised edge and a concave shape inside, similar to a crater; the edge has a broken point 45 protruding from other parts, that is, the crater has a raised peak.

[0024] The hole nail 40 includes a mounting tube 43,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com