Drone inspection operation assisting system for power line

A technology for auxiliary systems and power lines, which is applied to aircraft parts, bolting devices, ground devices, etc., can solve the problems of bulky supporting equipment boxes, reduce operating efficiency, labor and labor, etc., and achieve simple and compact overall structure, low manufacturing cost, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

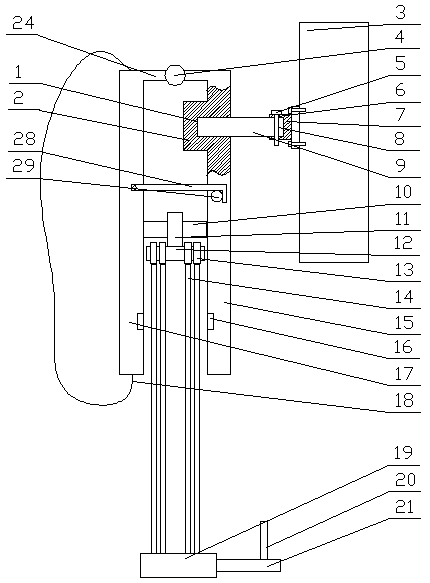

[0045] Embodiment 1, the present invention provides an auxiliary system for power line UAV inspection operations, including a foldable lifting platform 25, a foldable lifting base for supporting the lifting platform 25, and a folding base set on the lifting platform 25. A fixing mechanism for fixing the UAV;

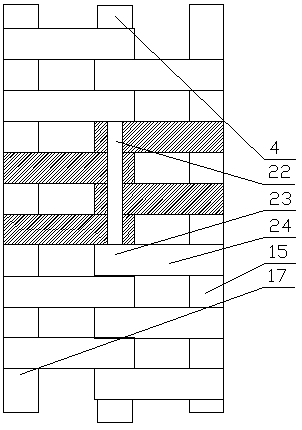

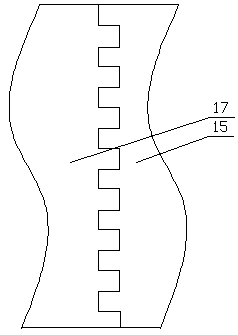

[0046] The landing platform 25 includes a left side plate 17 and a right side plate 15 that are hinged together, and a side where the left side plate 17 and the right side plate 15 are connected is provided with several connecting rods 24 alternately, and the connecting rods 24 The lower end is provided with a rotating cylinder 23, and the central axes of several rotating cylinders 23 overlap. The rotating shaft 22 is inserted into the rotating cylinder 23, the two ends of the rotating shaft 22 are provided with stoppers 4, and the left side plate 17 is provided with two A strap 18, the two ends of the strap 18 are respectively connected to the two sides of the left side...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is:

[0051] The lifting base includes a vertical central shaft 12, four rotating rings 13 are arranged through four rotating slots 27 on the central rotating shaft 12, a cross bar 14 is arranged on the side of the rotating ring 13, and the other end of the cross bar 14 A lifting mechanism for supporting the landing platform is provided.

[0052] The cross-section of the strut 10 is rectangular, and the central rotating shaft 12 is provided with a rectangular frame 11 matched with the strut 10 .

[0053] The lifting mechanism includes a bottom sleeve 19 connected to the cross bar 14, the inside of the bottom sleeve 19 is provided with a lifting thread, and the upper end of the bottom sleeve 19 is inserted into a lifting rod 21, and the outer surface of the lifting rod 21 is arranged on the outside surface of the lifting rod 21. The external thread matched with the lifting thread, the upper part of the lifting rod ...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is:

[0057] The fixing mechanism includes an internally threaded hole 1 provided on the upper surface of the right side plate 15, and the lower surface of the right side plate 15 is provided with a thickened layer 2 on the lower surface of the position where the internally threaded hole 1 is provided, and the internally threaded hole 1 A fixed rod 9 is inserted inside, the other end of the fixed rod 9 is provided with a first pin hole 8, and the lower surface of the drone 3 is bolted to be provided with a fixed sleeve 7 cooperating with the fixed rod 9, and the fixed sleeve 7 A second pin hole 6 cooperating with the first pin hole 8 is arranged on the top, and the pin 5 is inserted into the first pin hole 8 and the second pin hole 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com