Manufacturing and boxing integrated equipment for packing box for pop-top cans

A technology for pop-top cans and packaging boxes, which is applied in the field of integrated equipment for manufacturing and packaging of packaging boxes for pop-top cans, can solve the problems of low work efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

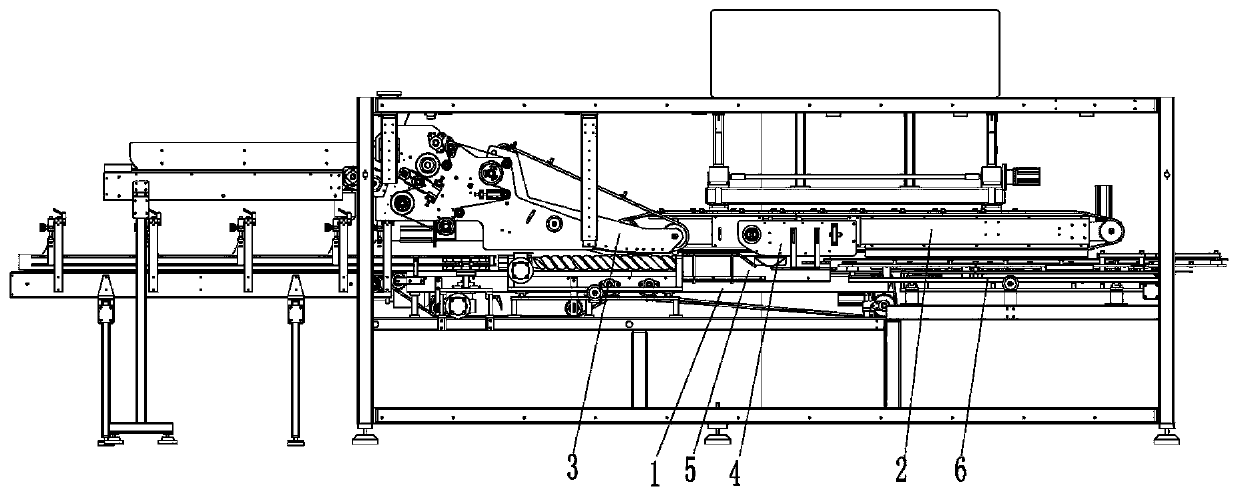

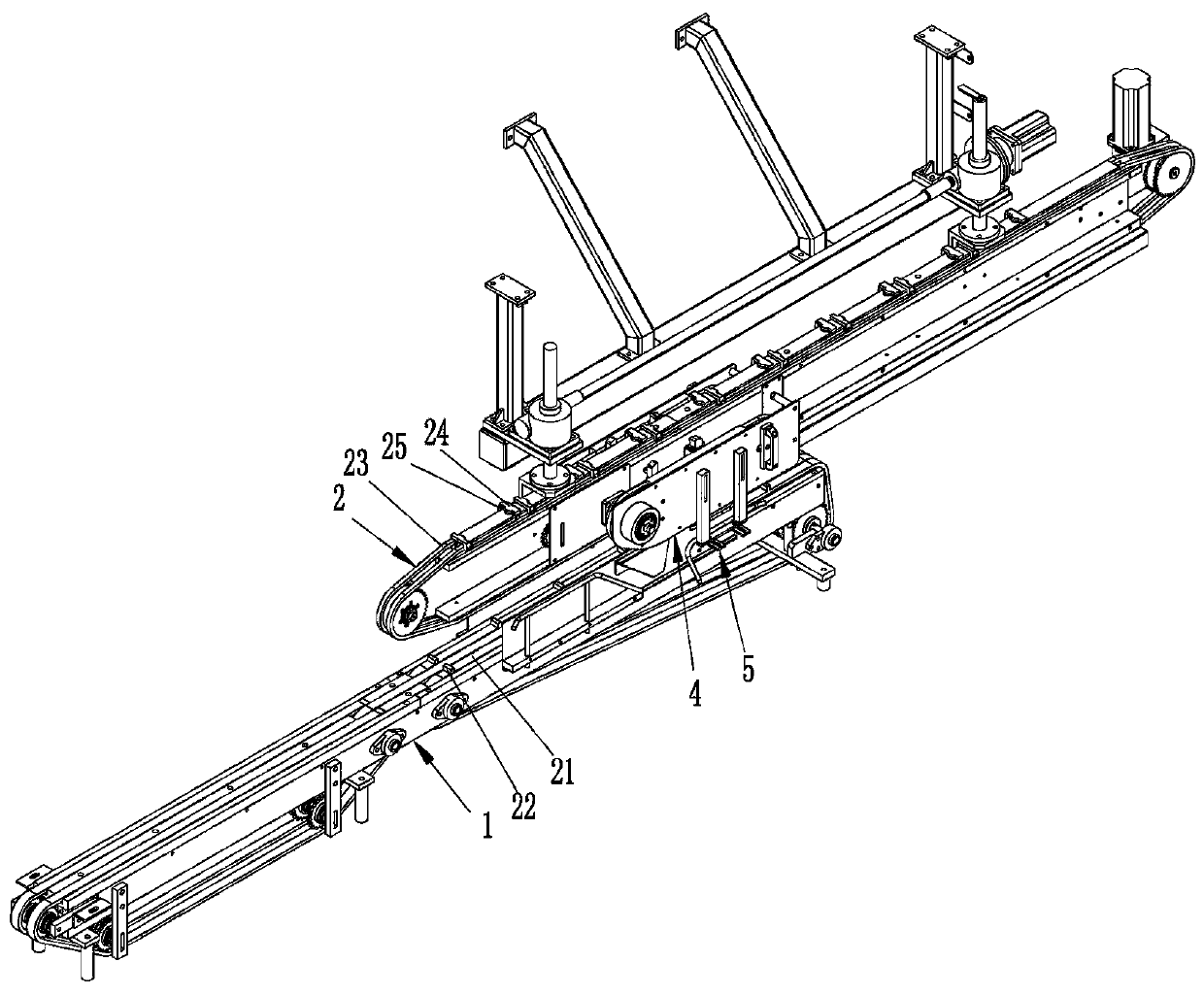

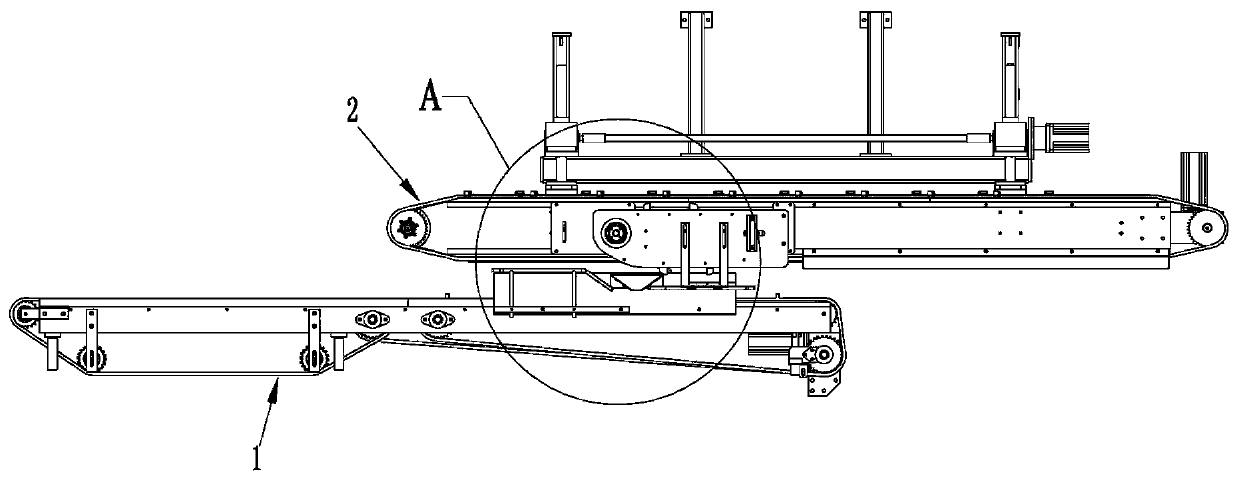

[0029] like figure 1 , 2 , 3, an integrated equipment for the manufacture and packing of packaging boxes for pop cans, including a first conveying device 1 for conveying pop cans in groups, a second conveying device 2 arranged above the first conveying device 1 for conveying cardboard, docking on the second Two conveying device 2 input ends and convey the paper feeding device 3 of cardboard to the second conveying device 2, be respectively arranged on the two sides of the second conveying device 2 and the two sides pressing device 4 that folds down the front and rear sides 104 of the cardboard, be located at Between the side pressing device 4 and the second conveying device 2, the origami device 5 that folds down the side plate 102 of the cardboard being conveyed and the first conveying device 1 that is docked at the output end of the first conveying device 1 and folds the bottom plate of the cardboard inwards to wrap the can can Three conveying devices 6 .

[0030] like F...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap