Preparation method of solvent-based PU flocking glue

A flocking adhesive and solvent-based technology, which is applied in the preparation of solvent-based PU flocking adhesive and in the field of flocking adhesive, can solve the problems of difficult to effectively control flocking quality and increased viscosity, and meet the requirements of flocking wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

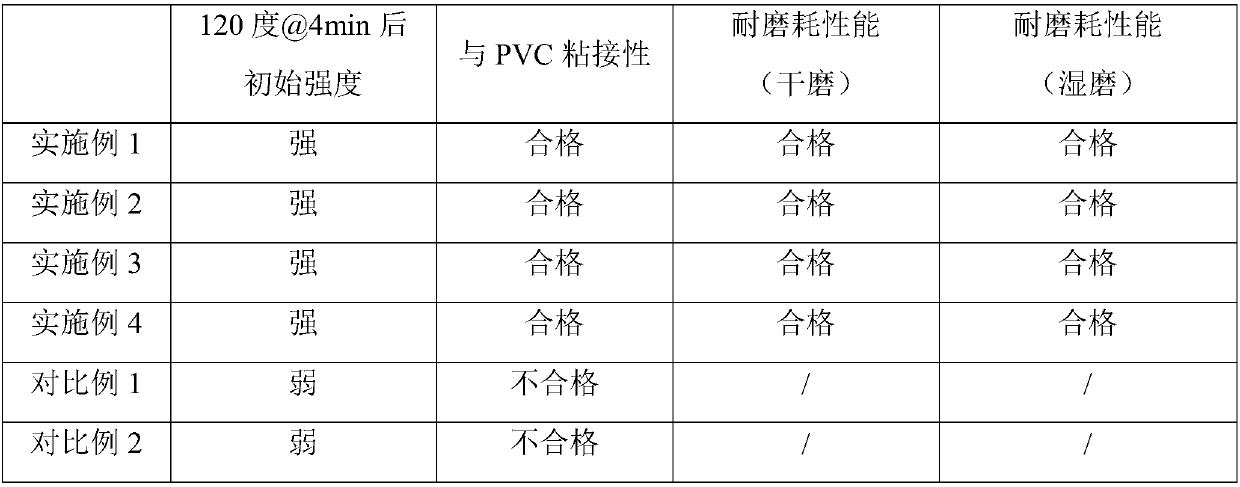

Examples

preparation example Construction

[0011] The preparation method of solvent-based PU flocking glue of the present invention, it comprises the following steps: (a) polyester diol, polyester triol and thermoplastic TPU are dissolved in the mixed solvent, and dehydration obtains the first mixture; The polyester The mass ratio of diol, polyester triol and thermoplastic TPU is 100:40~60:15~25; (b) Add liquefied MDI to the first mixture, mix well and seal it for several days, and adjust to solid The content is 38-43%, and the viscosity is 200-400cps; the NCO / OH value (molar ratio) in the above materials is 1.4-1.8. By mixing the first mixture of specific components with liquefied MDI and adjusting the solid content and viscosity of the product, it can be directly used in the flocking process of PVC sealing strips without on-site preparation, and the curing conditions meet the online flocking process (120℃@3~5min) (that is, high temperature fast curing) requirements, and meet the requirements of flocking wear resistan...

Embodiment 1

[0015] The present embodiment provides a kind of preparation method of solvent type PU flocking glue, it may further comprise the steps:

[0016] (a) 100 parts of polyester diol (usually polybutylene adipate, molecular weight is about 2000), 50 parts of polyester triol (molecular weight is about 400) and 20 parts of thermoplastic TPU (activation temperature 55~65℃) dissolved in a mixed solvent (cyclohexanone:butanone=1:2, volume ratio), and dehydrated to obtain the first mixture;

[0017] (b) Add 100 parts of liquefied MDI to the first mixture, and after sealing, shake and mix continuously for 10 to 15 hours with a shaker, then seal and let stand for 3 days, and adjust to a solid content of 38 to 43% and a viscosity of 200 ~400cps is enough.

Embodiment 2

[0019] The present embodiment provides a kind of preparation method of solvent-based PU flocking glue, and it is basically consistent with embodiment 1, and difference is: in step (a), polyester diol, polyester triol and thermoplastic TPU The addition amounts are 100 parts, 50 parts and 25 parts respectively.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap