A sliding wire electric loader

A loader and electric technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of electric shock injury, tearing, pulling down tower or column, etc., to eliminate safety accidents, prevent electric shock accidents, Avoid strong impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

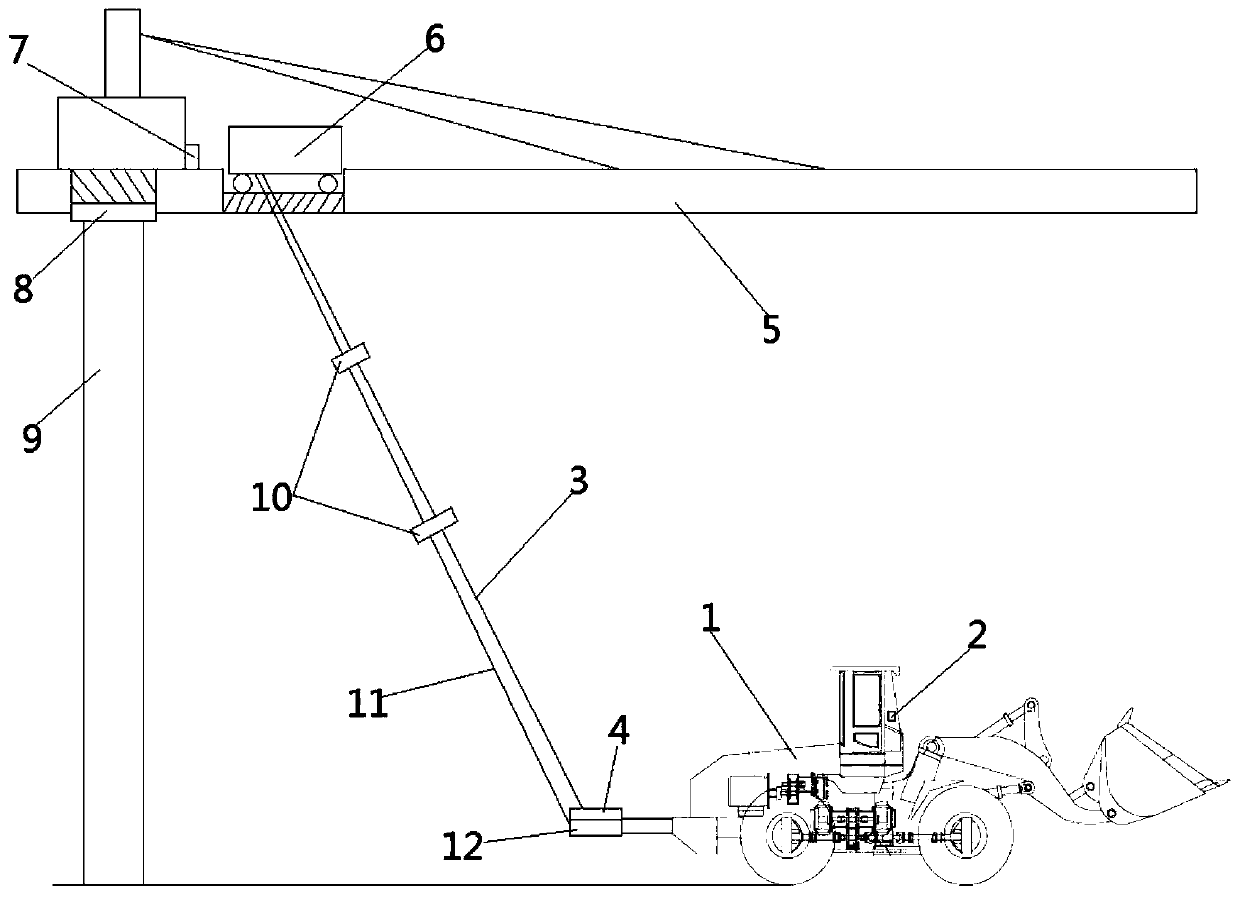

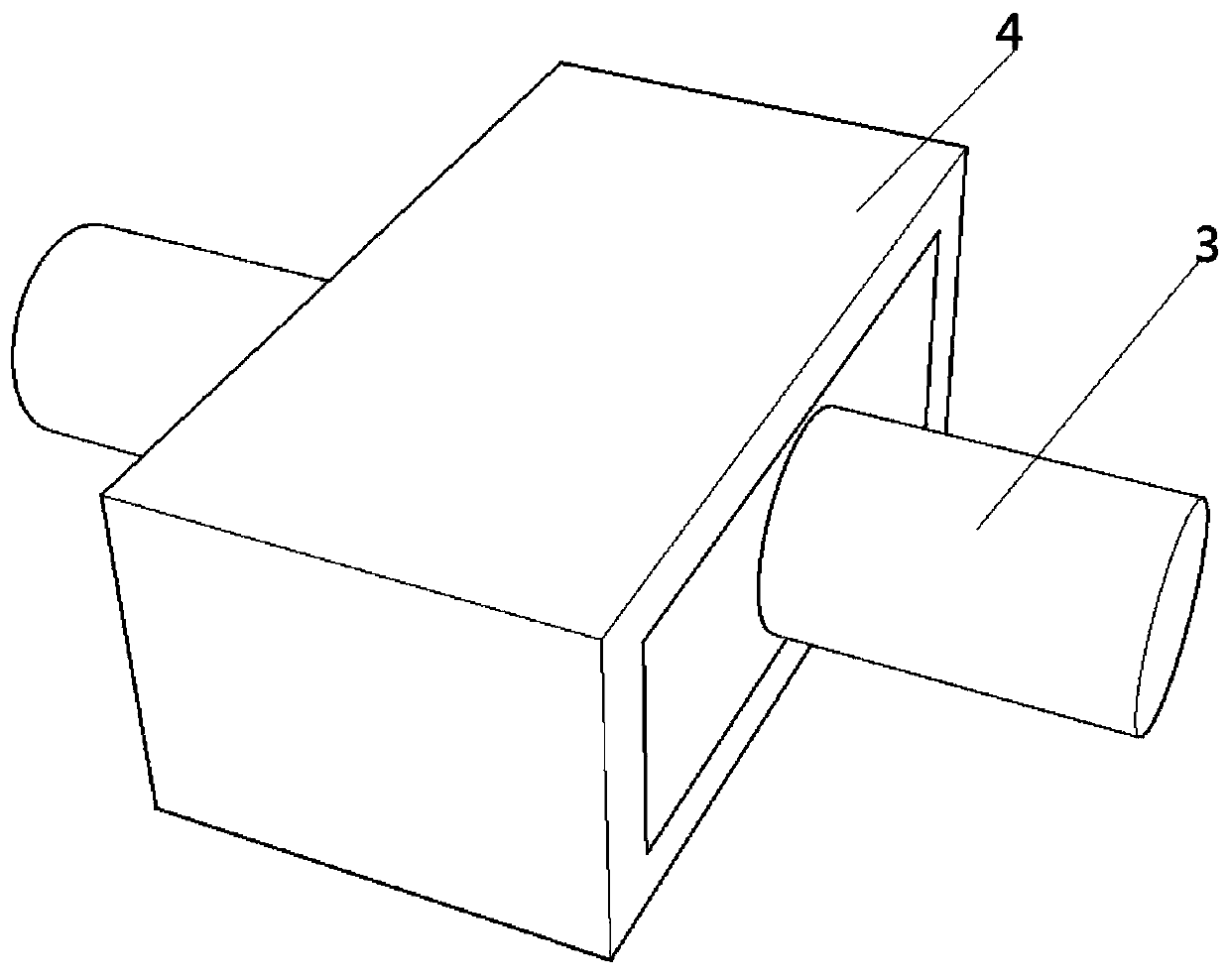

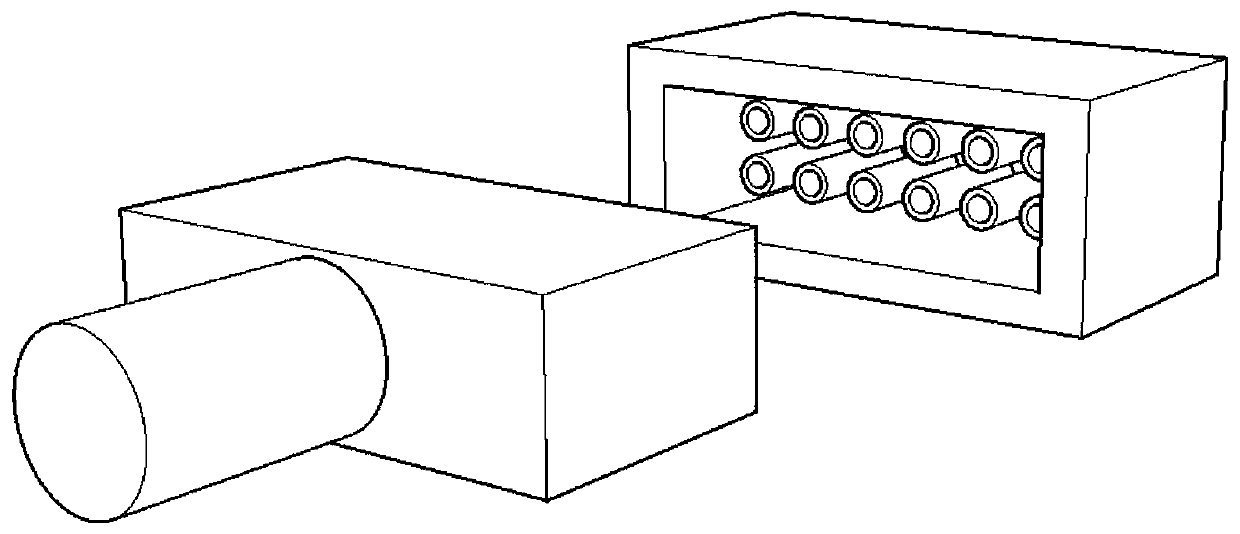

[0024] A sliding-wire electric loader, characterized in that: the sliding-wire electric loader includes an alarm device 2 installed in the cab of the electric loader 1, the alarm device 2 adopts a buzzer alarm, and the electric A cable plug device 4 is installed on the loader 1, one end of the cable plug device 4 is connected to the cable 3, and the other end is connected to the vehicle controller of the electric loader 1, and the cable plug device 4 adopts multiple Core built-in plug device.

[0025] Optionally, the slide wire electric loader also includes a traction chain 11, which is connected to the electric loader 1 through a buckle device 12, and the buckle device 12 is fixedly installed on the electric loader 1, so The buckle device 12 is disconnected by the overload tension of the electric loader 1; the traction chain 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com