Manipulator capable of clamping plastic parts

A technology for manipulators and plastic parts, applied in the field of manipulators, can solve problems such as easy burns to the body, insufficient structural strength, long labor hours, etc., and achieve the effects of overcoming personnel burn safety accidents, reducing personnel labor intensity, and improving product qualification rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

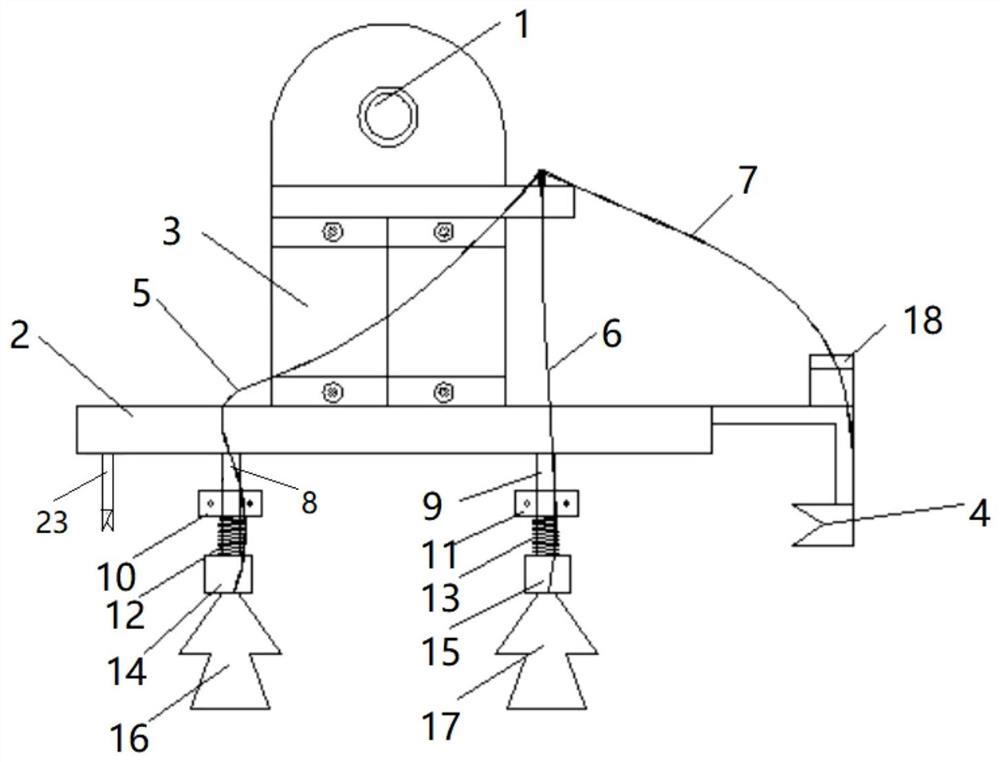

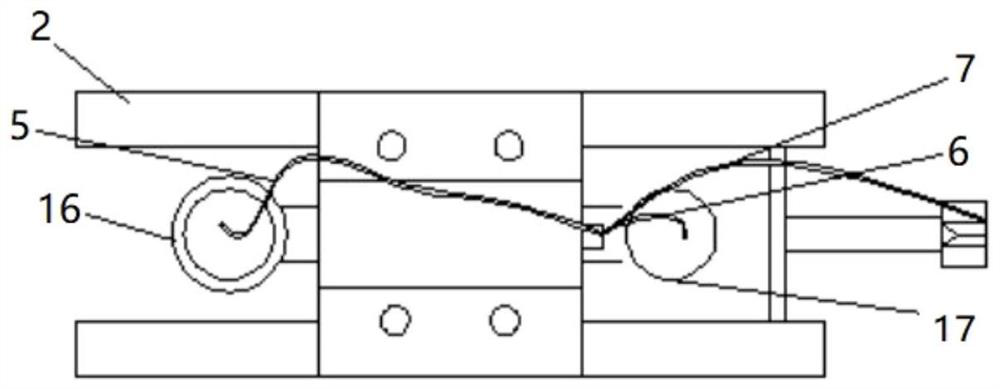

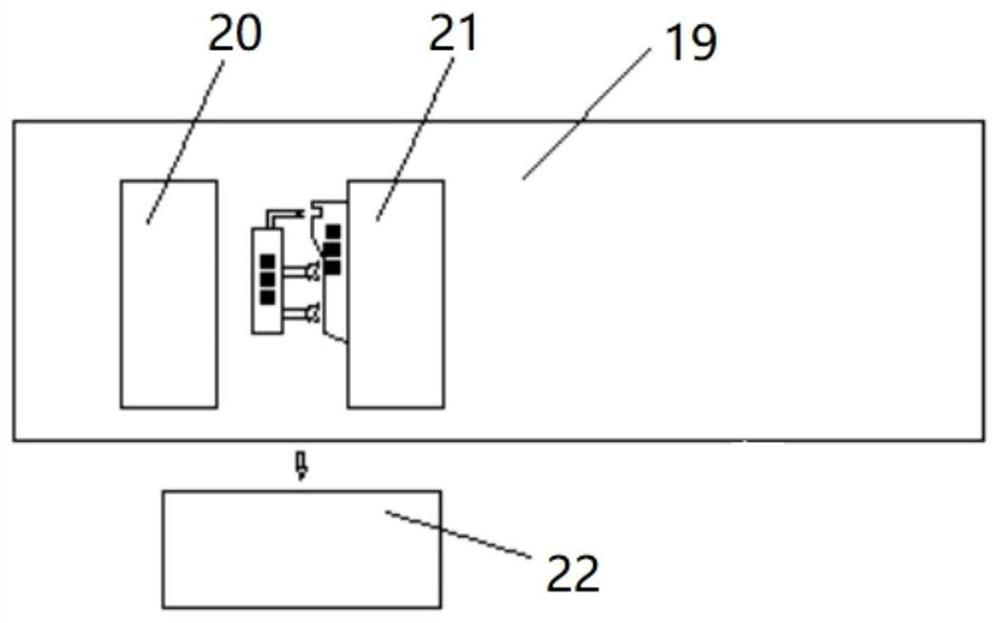

[0027] Such as Figure 1-3 As shown, the present invention includes a rotating shaft mechanism 1, and a cylinder 3 is arranged below the rotating shaft mechanism 1, and the cylinder 3 is connected to the first rubber sucker 16, the second air pipe 7 through the first air pipe 5, the second air pipe 6, and the third air pipe 7 respectively. Rubber sucker 17 and metal collet 4, described cylinder 3 is fixed on the top of table top 2, first connecting rod 8, second connecting rod 9 are connected below described table top 2, described first rubber sucker 16, second rubber The suction cup 17 is connected below the first connecting rod 8 and the second connecting rod 9 .

[0028] Buffer structures are respectively provided between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com