Method for preventing and controlling cast-in-place concrete lining structure cracks

A control method and concrete technology, which can be applied in shaft lining, earthwork drilling, tunnel lining, etc., can solve problems affecting the durability of tunnels and underground engineering, reducing engineering safety, and increasing the permeability of lining structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

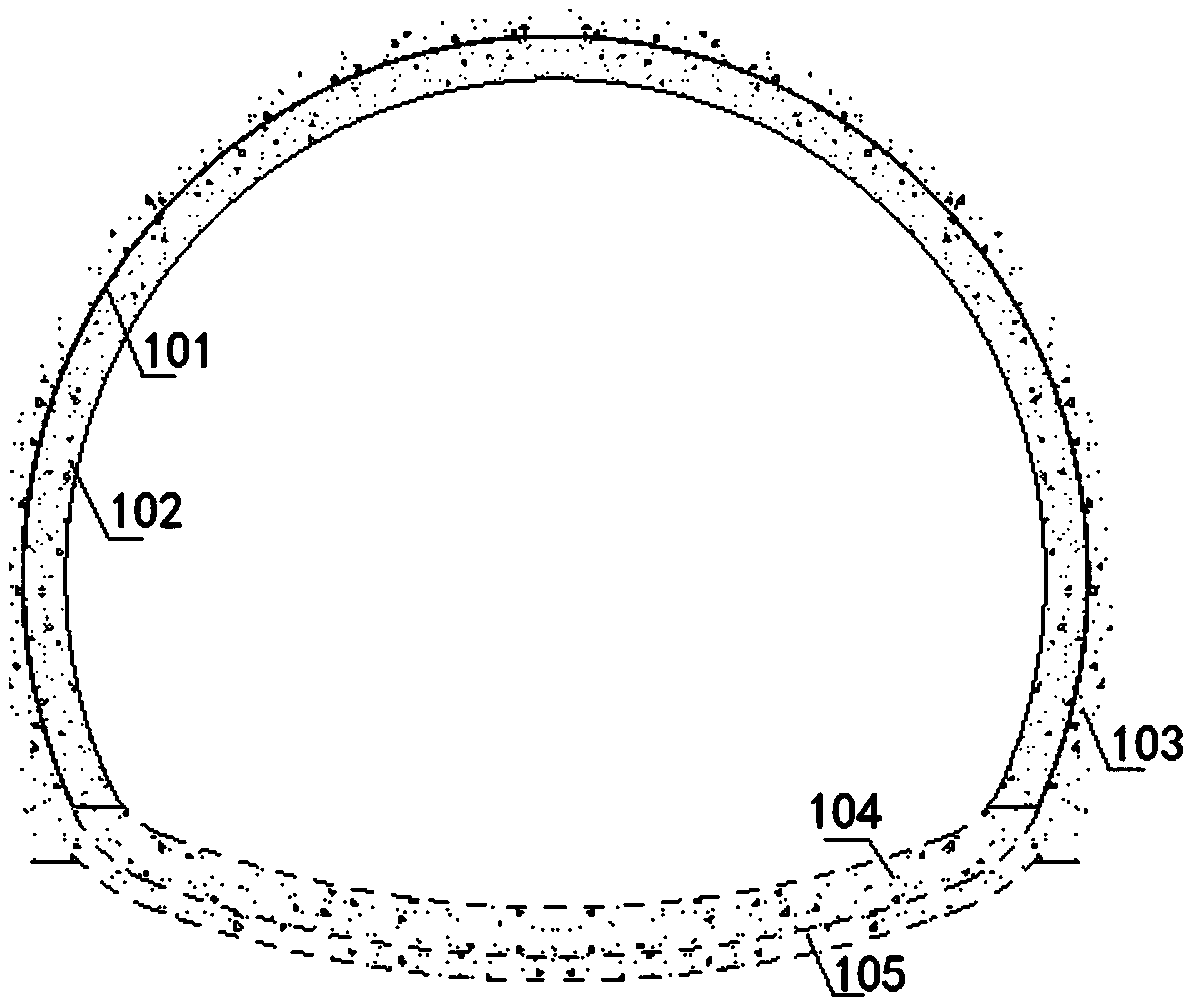

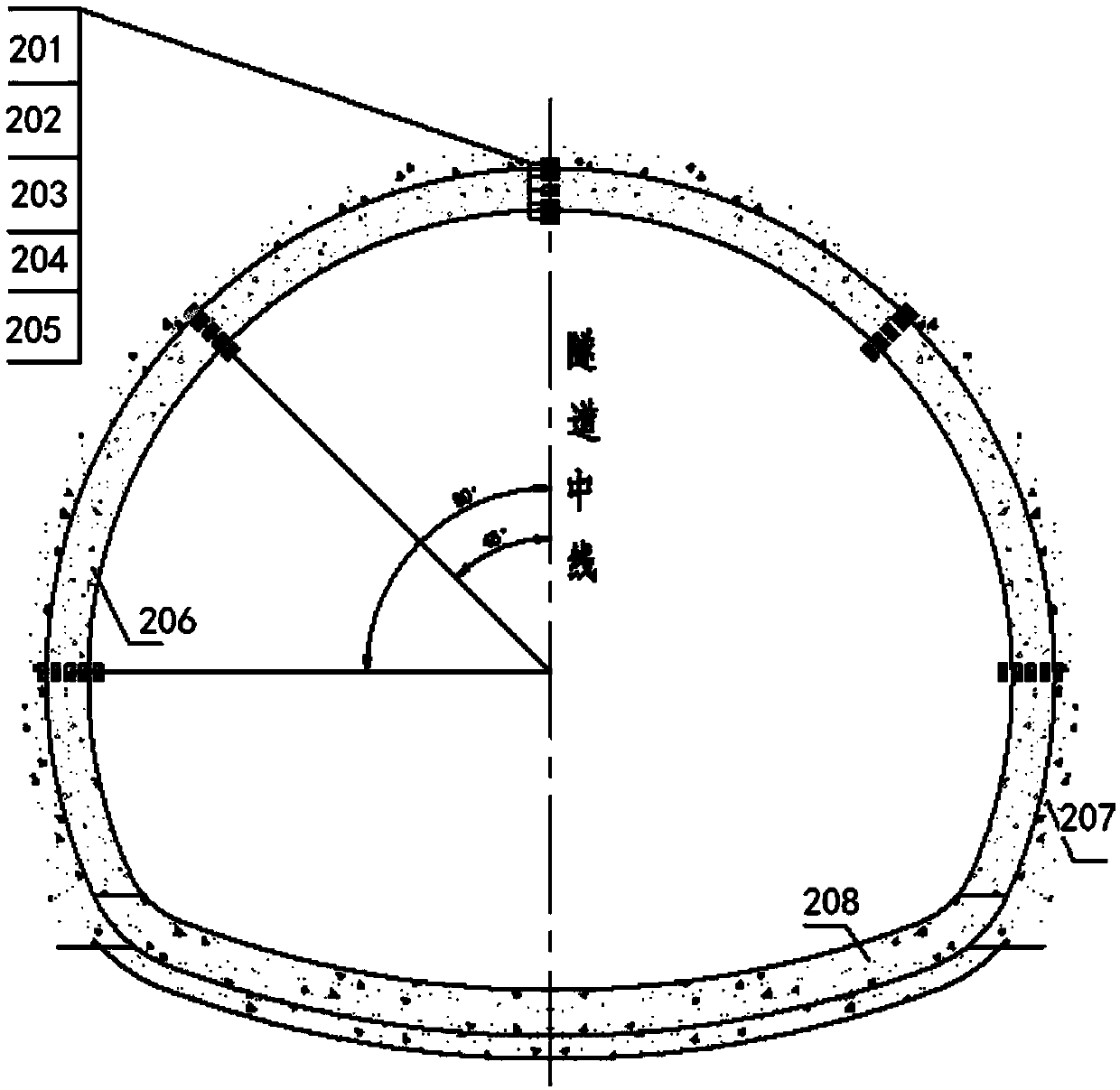

[0030] Attached below Figure 1-5 , a specific embodiment of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

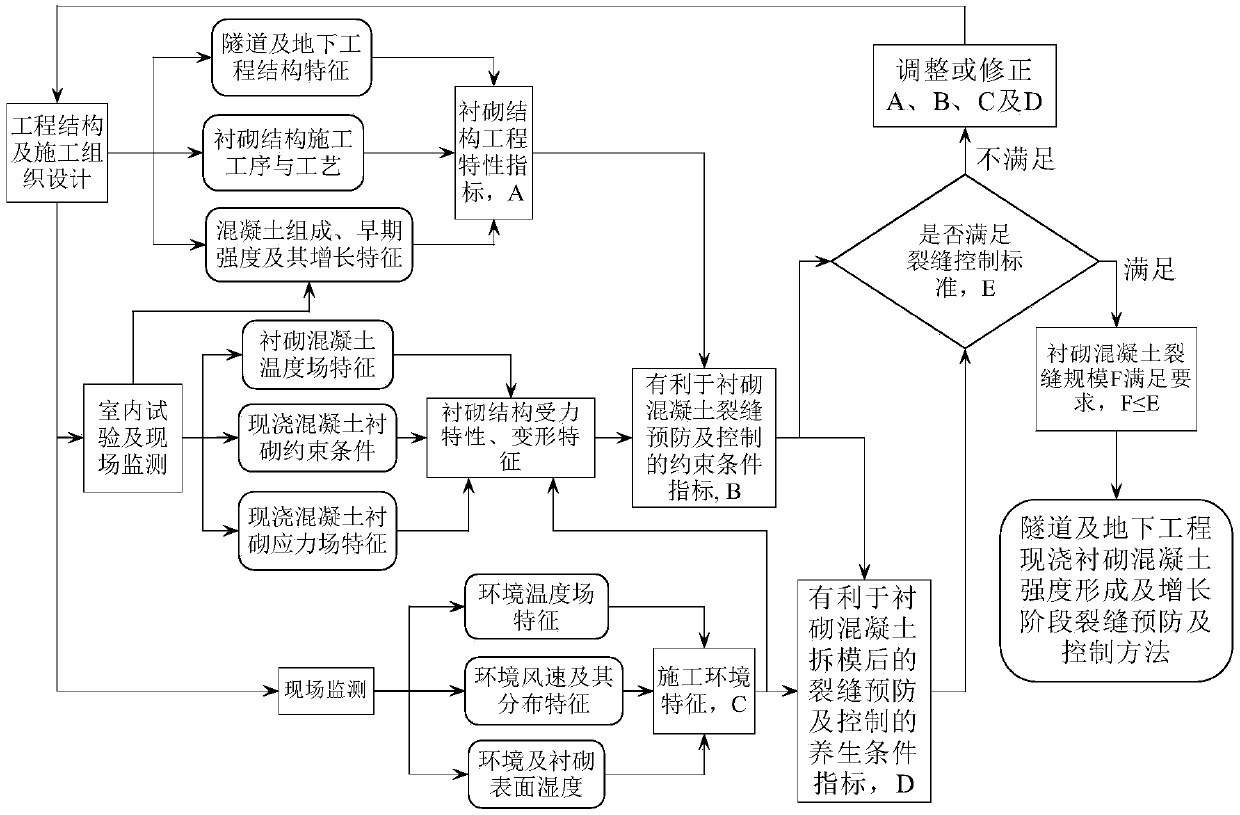

[0031] Such as figure 1 As shown, a method for preventing and controlling cracks in a cast-in-place concrete lining structure provided by the embodiment of the present invention is a dynamic design and construction concept of tunnel and underground engineering based on the engineering behavior of the lining structure applied to the formation and growth of the strength of the cast-in-place concrete lining The dynamic process of stage crack prevention and control; based on the structural properties and constraints of the cast-in-place concrete lining and the crack control objectives of the lining concrete, the principle of setting a flexible layer on the outside of the cast-in-place lining is determined. Include the following steps.

[0032] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com