Detection system and method for hydraulic motor and engineering vehicle

A hydraulic motor and detection system technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., and can solve problems such as vehicle stall, personal and property safety threats, and heavy objects falling to the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

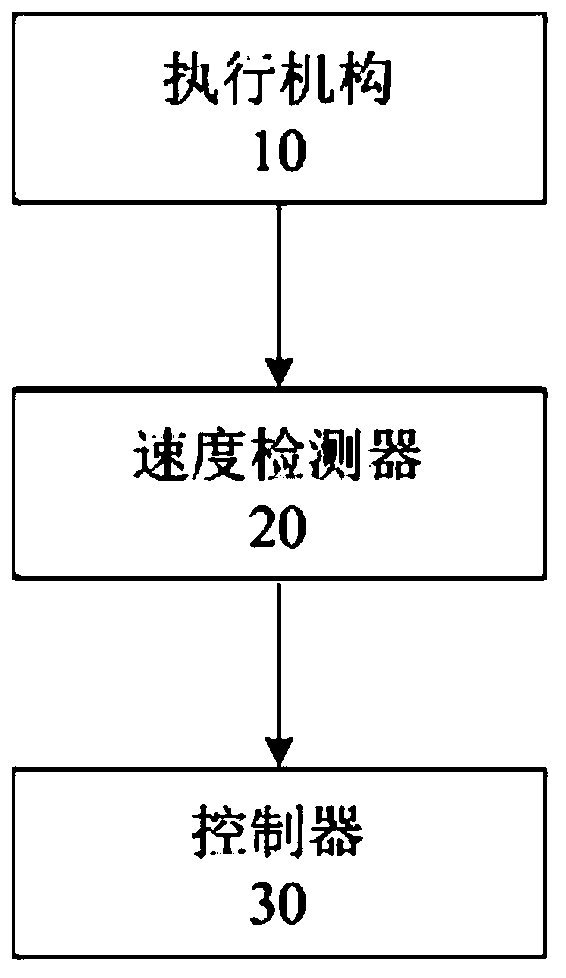

[0040] figure 1 It is a structural diagram of a detection system for a hydraulic motor provided by an embodiment of the present invention. Such as figure 1 As shown, the detection system for a hydraulic motor provided by the present invention may include: an actuator 10 whose lifting or lowering is driven by the hydraulic motor; a speed detector 20 used to detect the actuator 10 The speed of lifting or lowering; the controller 30 is used to perform the following operations: output an electric signal to control the input flow rate of the hydraulic motor, thereby controlling the lifting or lowering speed of the actuator 10; and according to the output The elect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap