Troubleshooting Method for Insulation Faults of Oil and Gas Pipeline Monitoring Valve Chamber

A technology for oil and gas pipelines and insulation failures, applied in instruments, testing dielectric strength, measuring devices, etc., can solve problems such as damage to insulation components, affecting the effect of cathodic protection, corrosion of oil and gas pipelines, etc., to ensure safety and ensure the effect of cathodic protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art.

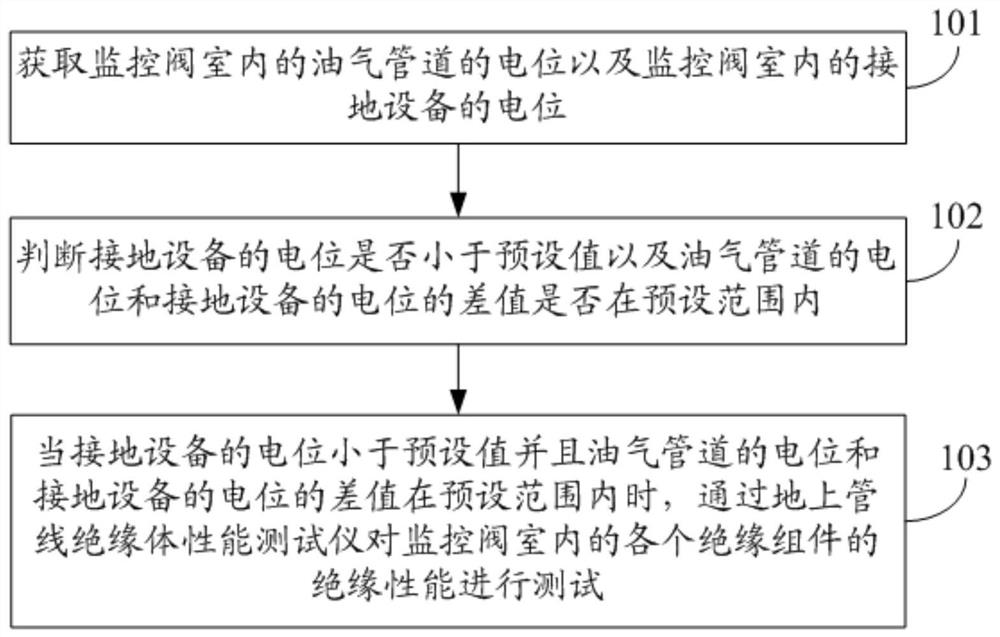

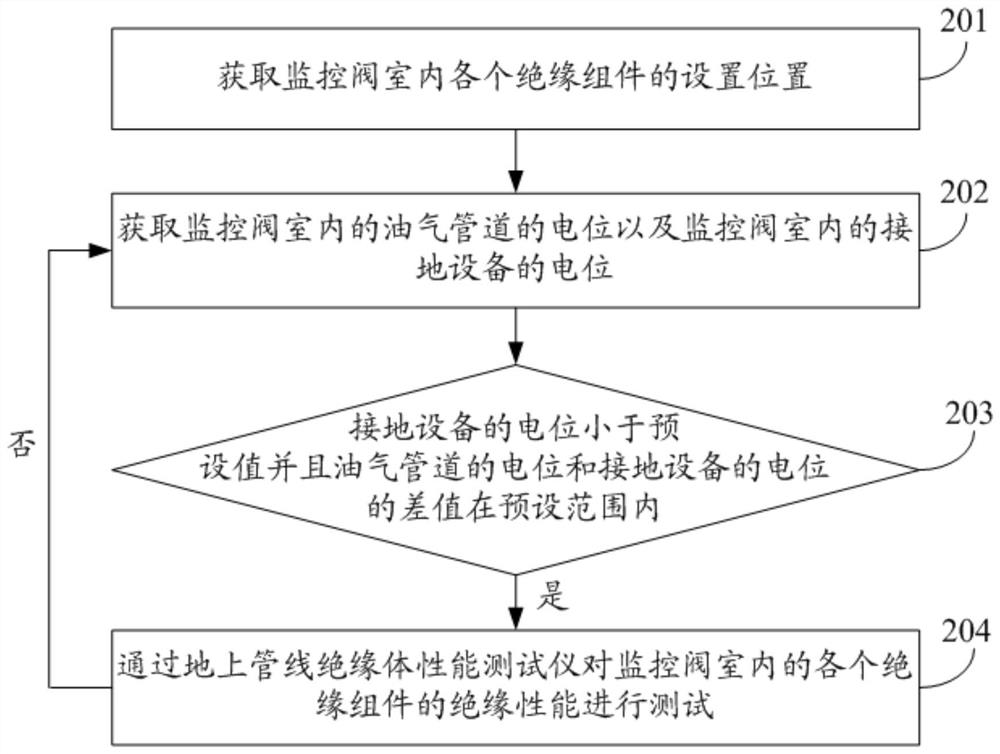

[0036] figure 1 It shows a method for troubleshooting the insulation fault of an oil and gas pipeline monitoring valve room, such as figure 1 As shown, the troubleshooting method includes the following steps:

[0037] Step 101, acquiring the potential of the oil and gas pipeline in the monitoring valve chamber and the potential of the grounding equipment in the monitoring valve chamber.

[0038] Step 102, judging whether the potential of the grounding device is lower than a preset value and whether the difference between the potential of the oil and gas pipeline and the potential of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com