Automatic plug inserting machine for hub valve holes

A valve hole and plugging machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effects of high efficiency, convenient operation, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

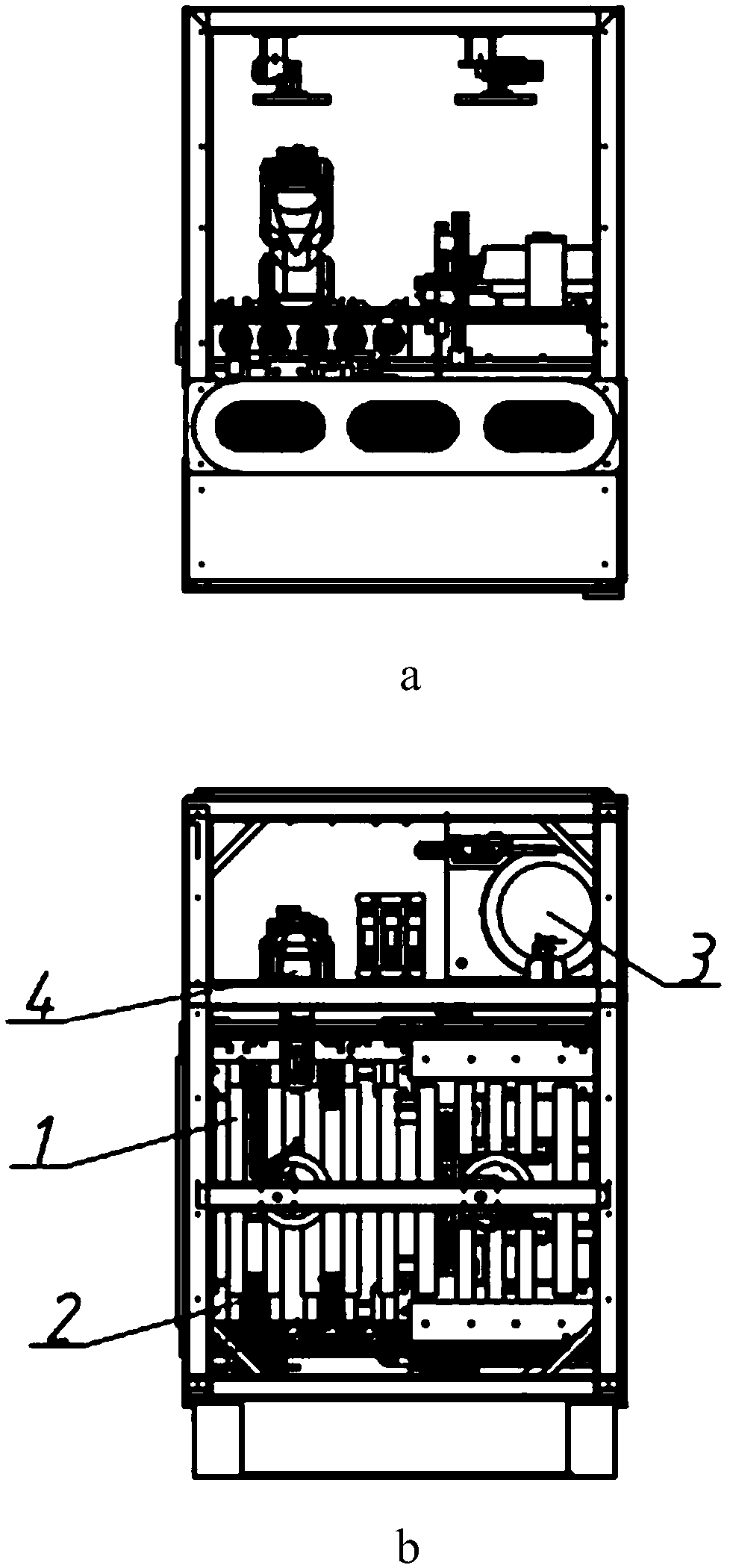

[0037] Such as Figure 1-5 Shown: the automatic hub valve hole plugging machine of the present invention includes the hub automatic conveying system 1, the hub automatic centering, rotation, positioning system / 2, the rubber plug automatic feeding system 3 and the robot automatic plugging system 4.

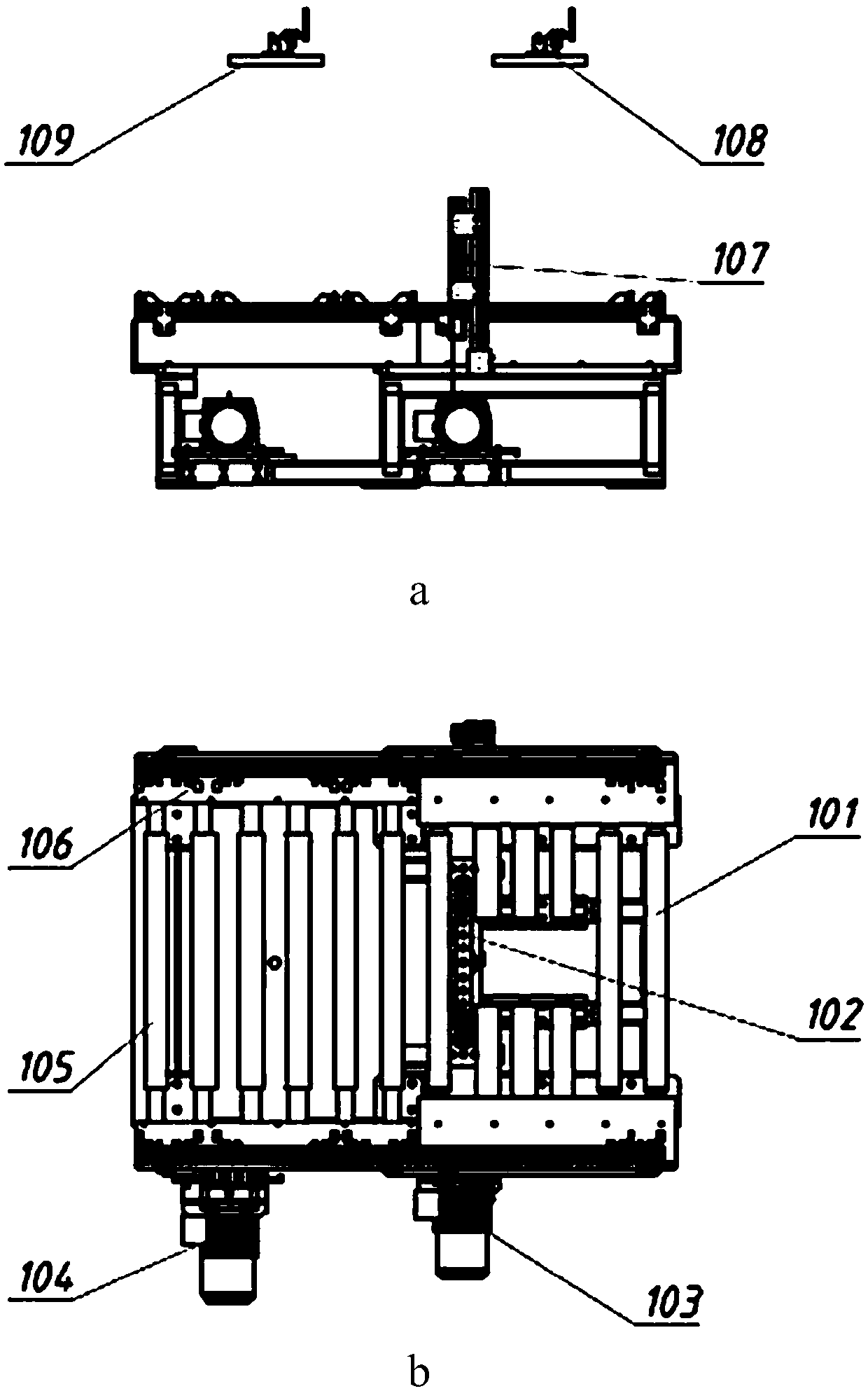

[0038] Such as figure 2 As shown, the structure of the wheel hub automatic conveying system 1 is as follows: comprising a first raceway 101, a stopper 102, a first raceway motor 103, a second raceway motor 104, a second raceway 105, a photoelectric switch 106, a height measuring A grating 107 , a first camera 108 , and a second camera 109 .

[0039] The first raceway motor 103 is connected and drives the first raceway 101, the second raceway motor 104 is connected and drives the second raceway 105, and the stopper 102 and the height measuring grating 107 are located between the first raceway and the second raceway , the first camera 108 is located above the first raceway, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com