Locomotive constant speed control method and locomotive control system

A control method and control algorithm technology, applied in locomotives and other directions, can solve problems such as difficulty in ensuring the smoothness of train operation, and achieve the effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] If a passenger locomotive needs to be driven at a constant speed, it is necessary to use a certain algorithm, using the set speed of the locomotive, the actual speed of the locomotive, the acceleration, the set force of the locomotive, the actual force of the locomotive, etc. , so as to achieve the best setting force required by the constant speed.

[0033] The algorithms used in the prior art all adjust the speed of the locomotive by adjusting the setting force of the locomotive, so as to stabilize the actual speed of the locomotive near the set speed. Such as figure 1 As shown, the PI algorithm or PID algorithm used by most of the existing passenger locomotives uses the difference between the set speed and the actual speed of the locomotive as the input of the algorithm, takes the set force as the output of the algorithm, and calculates the set speed through the speed difference. Force, in order to achieve constant speed control.

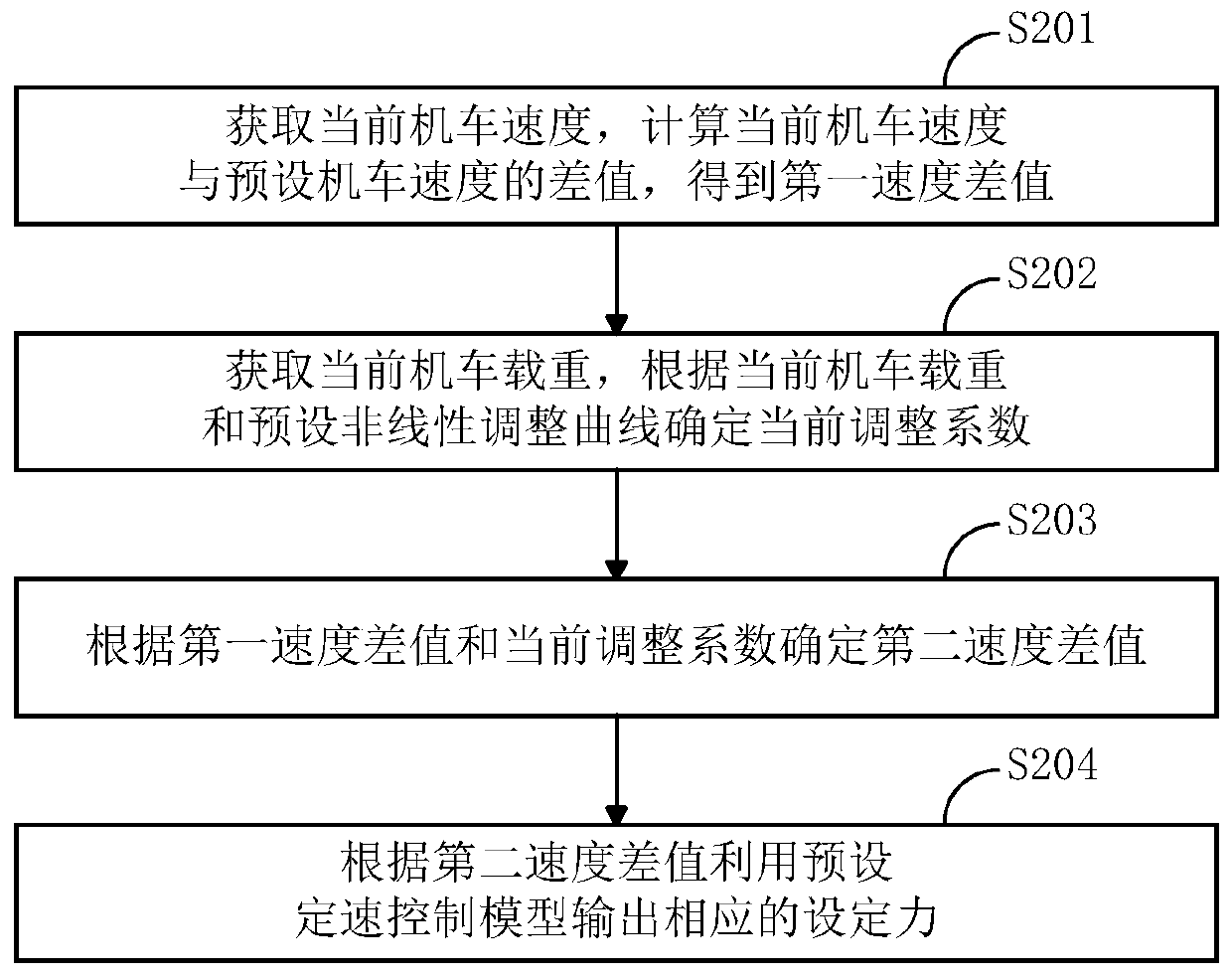

[0034] A constant speed control me...

Embodiment 2

[0045] The operating conditions of electric locomotives are often complex. Faced with complex working conditions, a constant speed control algorithm often cannot meet various external conditions. At the same time, any control algorithm itself has certain limitations, for example, in the PID control algorithm, the system has a contradiction between response speed and overshoot.

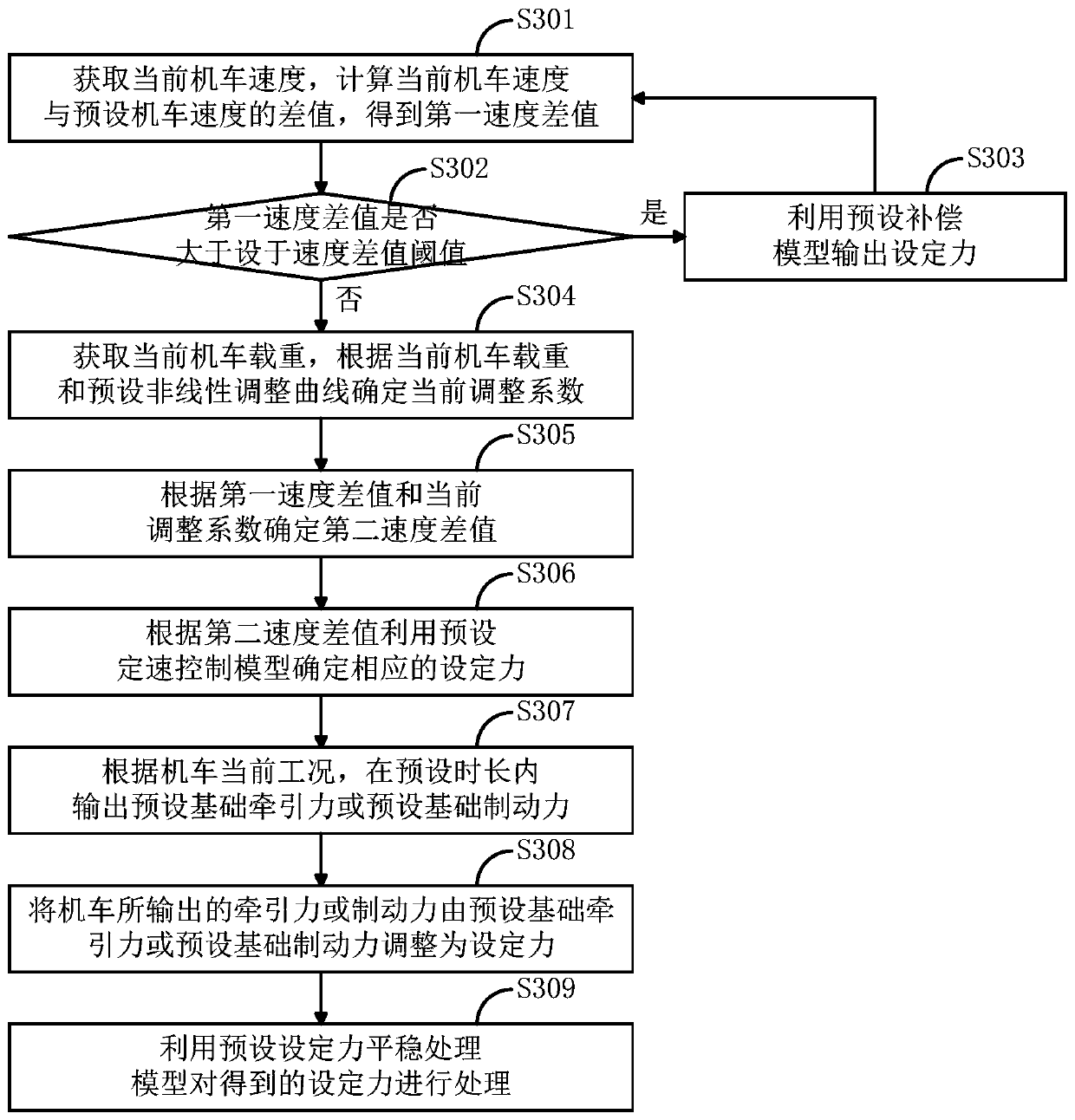

[0046] In view of the above problems, the locomotive constant speed control method provided in this embodiment adopts a multi-model control strategy, that is, a compensation control model is added on the basis of the method provided in the embodiment, so that the compensation control model can be used according to specific working conditions Or the non-linear adjustment model as shown in the first embodiment is used to control the constant speed of the locomotive.

[0047] Specifically, the locomotive constant speed control method provided in this embodiment will determine whether the current constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com