A Color Blindness Checker

A checker and colorblindness technology, applied in the field of checkers, can solve problems such as inconvenience, inability to combine multiple colors and effectively perform colorblindness inspection, and achieve the effect of good effect and convenient colorblindness inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

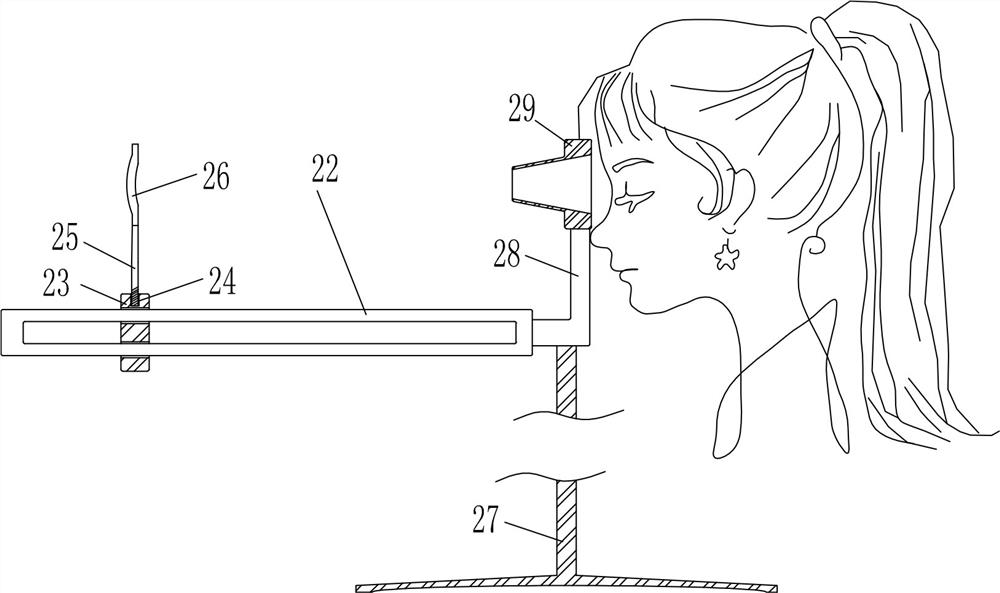

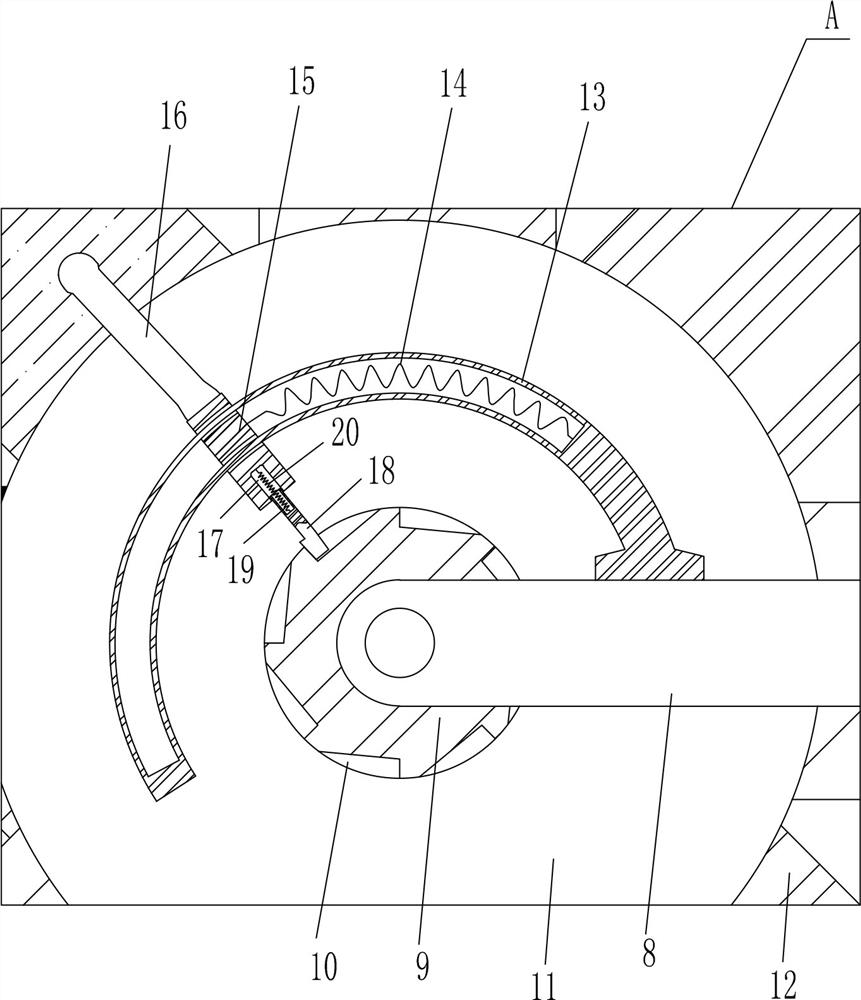

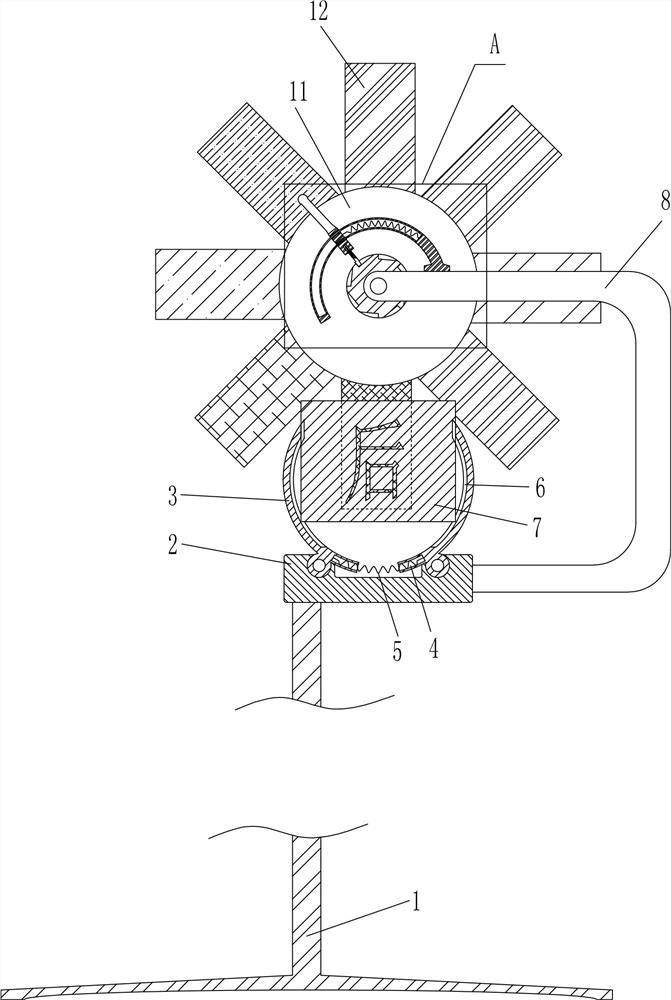

Embodiment 1

[0022] A color blindness checker such as Figure 1-6 As shown, it includes a first circular base 1, a fixed plate 2, a splint 3, a first arc spring 5, a hollow plate 7, a first bracket 8, a chuck 9, a disc 11, a color plate 12, an arc Slide bar 13, second arc-shaped spring 14, arc-shaped sliding sleeve 15, first handle 16, block 18 and return spring 20, the top of the first circular base 1 is connected with fixed plate 2, and the left and right parts of fixed plate 2 The splint 3 is connected in a uniform rotation, the inner side of the splint 3 is provided with a chute 6, the bottom of the splint 3 is provided with a first groove 4, and the inner side of the two first grooves 4 is connected with a first arc spring 5, Between the two splints 3, a hollow plate 7 is slidably provided through a chute 6, the right end of the fixed plate 2 is connected with a first bracket 8, and the upper left part of the first bracket 8 is rotatably connected with a chuck 9, and the chuck 9 Ther...

Embodiment 2

[0024] A color blindness checker such as Figure 1-6 As shown, it includes a first circular base 1, a fixed plate 2, a splint 3, a first arc spring 5, a hollow plate 7, a first bracket 8, a chuck 9, a disc 11, a color plate 12, an arc Slide bar 13, second arc-shaped spring 14, arc-shaped sliding sleeve 15, first handle 16, block 18 and return spring 20, the top of the first circular base 1 is connected with fixed plate 2, and the left and right parts of fixed plate 2 The splint 3 is connected in a uniform rotation, the inner side of the splint 3 is provided with a chute 6, the bottom of the splint 3 is provided with a first groove 4, and the inner side of the two first grooves 4 is connected with a first arc spring 5, Between the two splints 3, a hollow plate 7 is slidably provided through a chute 6, the right end of the fixed plate 2 is connected with a first bracket 8, and the upper left part of the first bracket 8 is rotatably connected with a chuck 9, and the chuck 9 Ther...

Embodiment 3

[0027] A color blindness checker such as Figure 1-6 As shown, it includes a first circular base 1, a fixed plate 2, a splint 3, a first arc spring 5, a hollow plate 7, a first bracket 8, a chuck 9, a disc 11, a color plate 12, an arc Slide bar 13, second arc-shaped spring 14, arc-shaped sliding sleeve 15, first handle 16, block 18 and return spring 20, the top of the first circular base 1 is connected with fixed plate 2, and the left and right parts of fixed plate 2 The splint 3 is connected in a uniform rotation, the inner side of the splint 3 is provided with a chute 6, the bottom of the splint 3 is provided with a first groove 4, and the inner side of the two first grooves 4 is connected with a first arc spring 5, Between the two splints 3, a hollow plate 7 is slidably provided through a chute 6, the right end of the fixed plate 2 is connected with a first bracket 8, and the upper left part of the first bracket 8 is rotatably connected with a chuck 9, and the chuck 9 Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com