B-type LNG ship enclosure system

An LNG ship and hull technology, which is applied in the direction of ship hull, ship construction, and some cabins in the hull, etc., can solve the construction and design workload of increasing the use area of low-temperature materials, insufficient clearance between the containment system and the hull structure, and increase the risk of low-temperature liquid leakage and other problems, to achieve the effect of saving peripheral clearance, reducing the scope of use, and reducing the evaporation rate of liquid cargo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

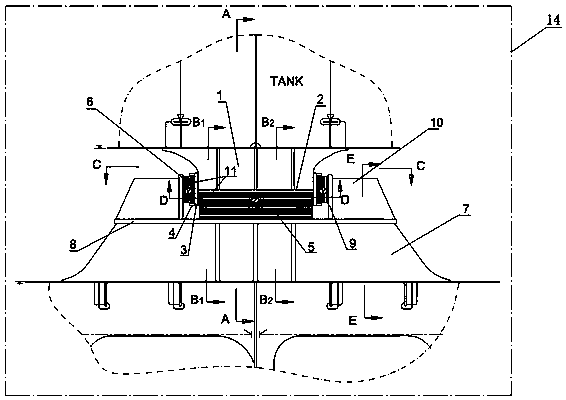

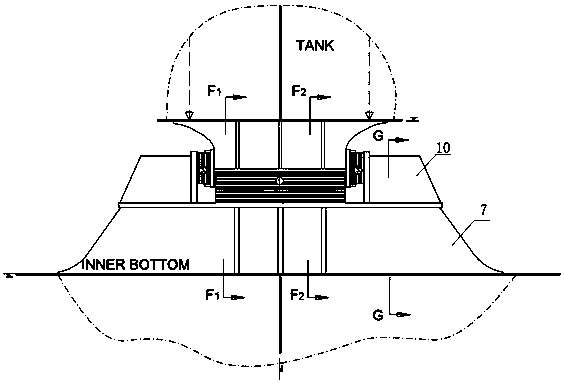

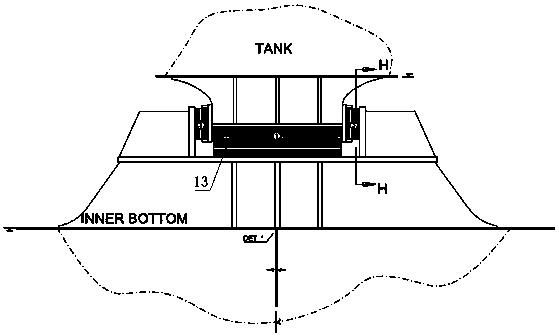

[0033] combine Figure 1-Figure 9 To illustrate this embodiment, the B-type LNG ship containment system support device of the present invention includes a lower support base, an upper support base, an intermediate pressure-bearing wood 5, a lower lateral support assembly, an upper lateral support assembly and an outer pressure-bearing wood 6. The lower support base is fixed on the hull structure, the upper support base is fixed on the bottom of the liquid car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com