B-type containment system supporting device and installation method of large lng ship

A technology for LNG ships and supporting devices, which is applied in ship components, ship construction, transportation and packaging, etc., can solve problems such as insufficient clearance between the containment system and the hull structure, increasing the risk of low-temperature liquid leakage, and destroying the integrity of the external insulation layer. , to achieve the effect of saving peripheral clearance, reducing self-weight, preventing roll and pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

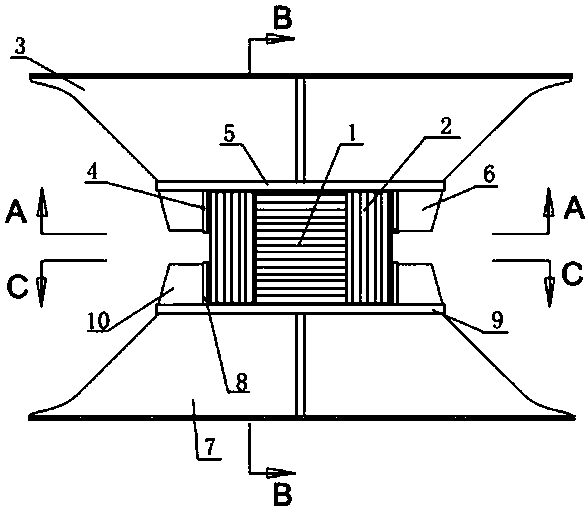

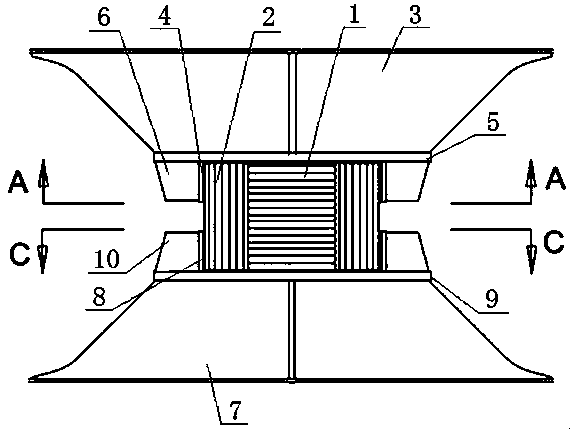

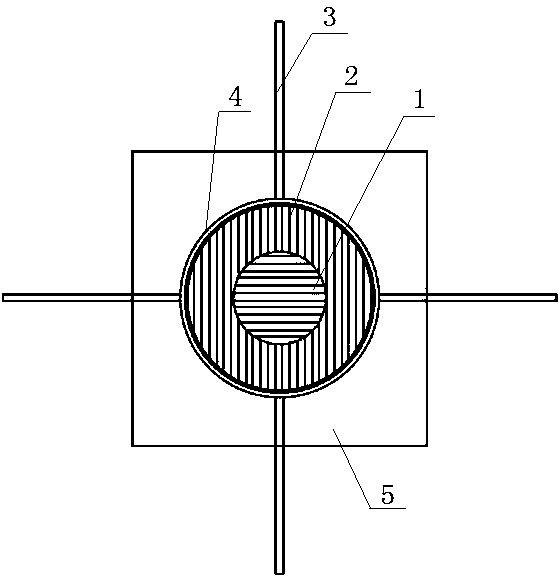

[0033] Such as Figure 1-Figure 7 As shown, the supporting device of the B-type containment system of the large-scale LNG ship in this embodiment includes a first cylindrical pressure-bearing wood 1 and a second cylindrical pressure-bearing wood 2, and the first cylindrical pressure-bearing wood 1 is Horizontally layered cylindrical pressure-bearing wood, the second cylindrical pressure-bearing wood 2 is a longitudinally layered tubular cylindrical pressure-bearing wood, and the second cylindrical pressure-bearing wood 2 is set on the first cylindrical bearing The periphery of the pressure wood 1 forms a supporting body, and the inner wall of the second cylindrical pressure wood 2 is bonded and fixed to the outer wall of the first cylindrical pressure wood 1.

[0034] The upper end surface of the supporting body is provided with an upper panel 5, and its lower end surface is provided with a lower panel 9, an upper cross bracket 3 is provided on the upper surface of the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com