Assembly method of a support device of a B-type LNG ship envelope system

A support device and LNG ship technology, applied in ship parts, ship construction, transportation and packaging, etc., can solve the problems of poor integrity of the external insulation layer, aggravate the sloshing of the liquid cargo tank of the LNG ship, destroy the external insulation layer, etc., and meet the structural strength requirements and fatigue requirements, reduce the evaporation rate of liquid cargo, and reduce the effect of the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

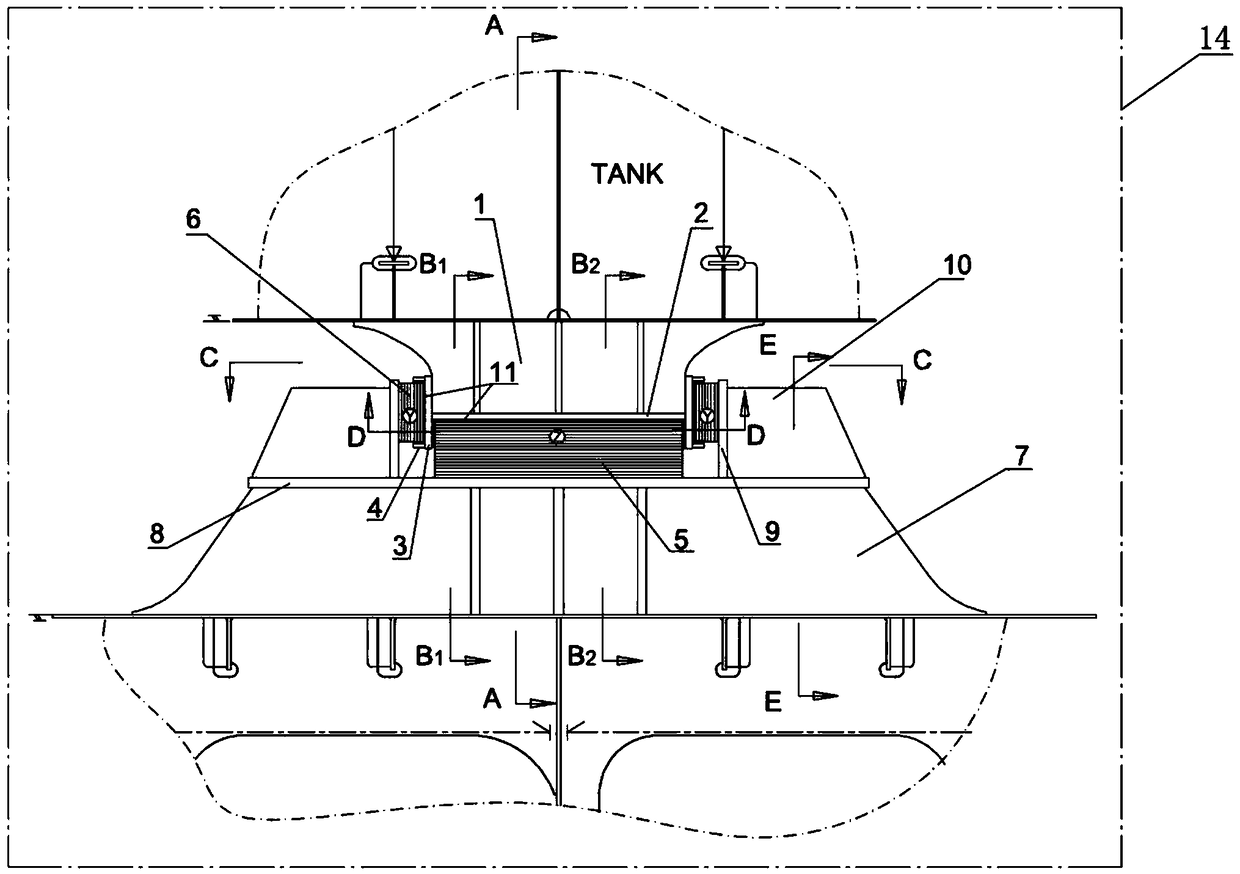

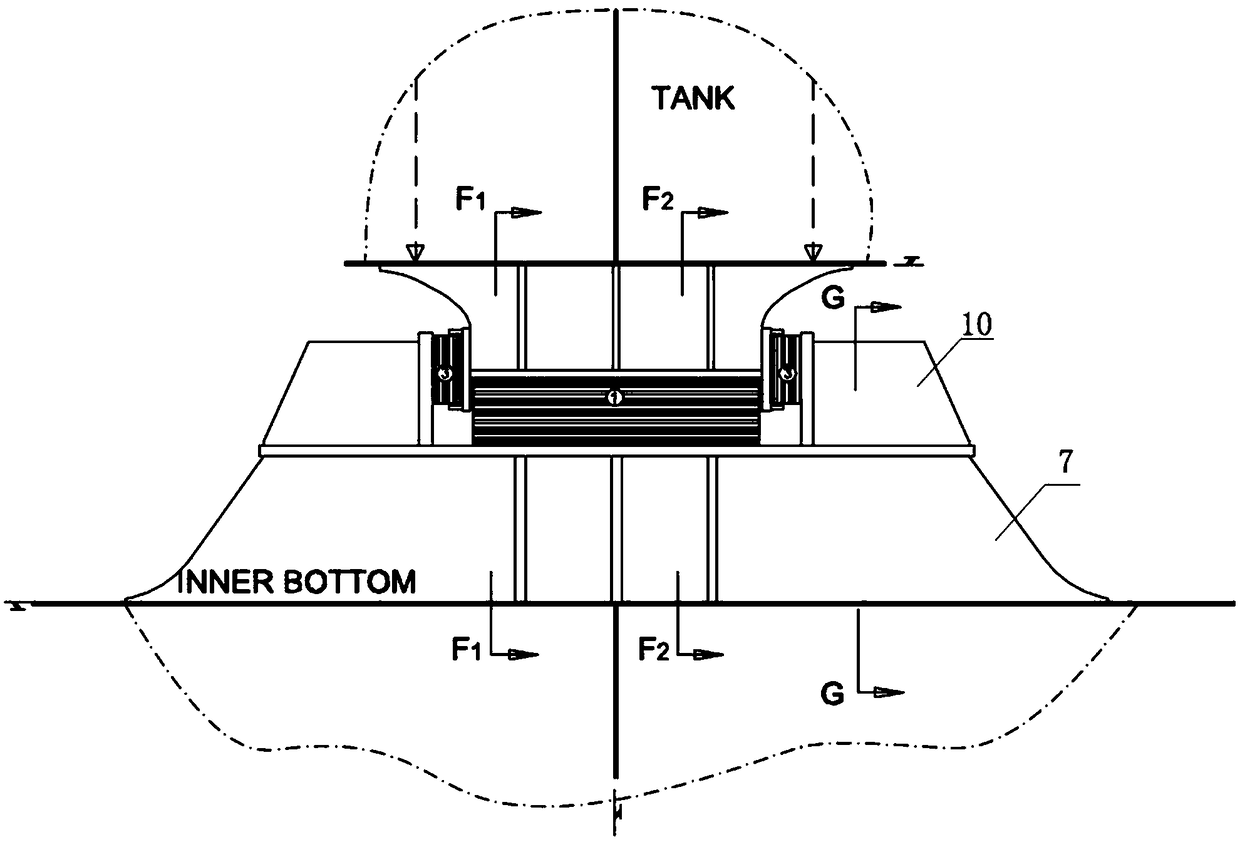

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

[0045] Combine below Figure 1-Figure 10 , specifically explain the specific embodiment of the present invention.

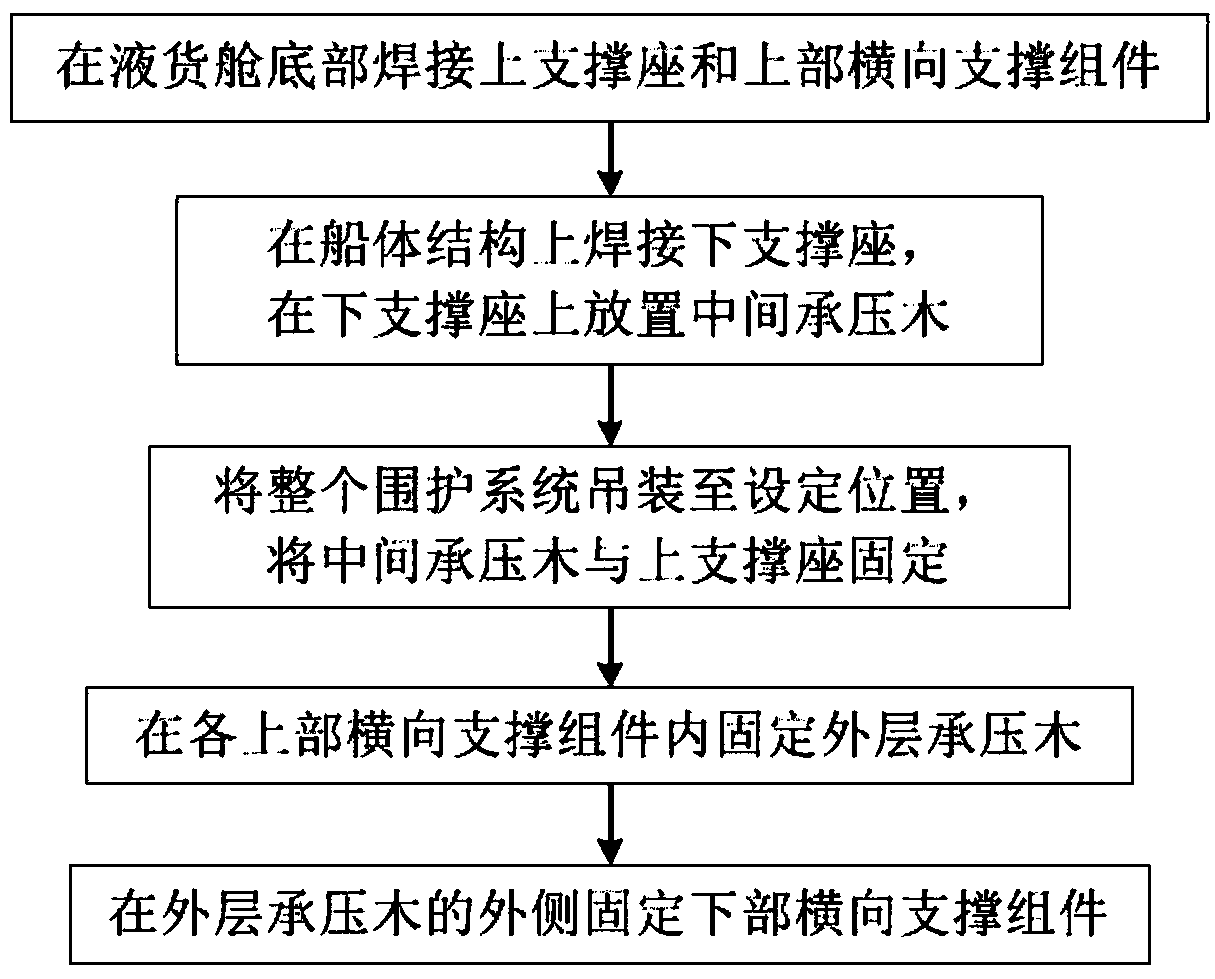

[0046] The assembly method of the B-type LNG ship containment system supporting device of the present invention specifically comprises the following assembly steps:

[0047] Step 1: Weld the upper support seat and upper lateral support assembly at the designed position on the bottom of the cargo tank body.

[0048] Specifically, firstly, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com