Bolt locking structure

A locking structure and bolt technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of small application range and poor welding performance, and achieve the effect of wide application range and avoiding loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

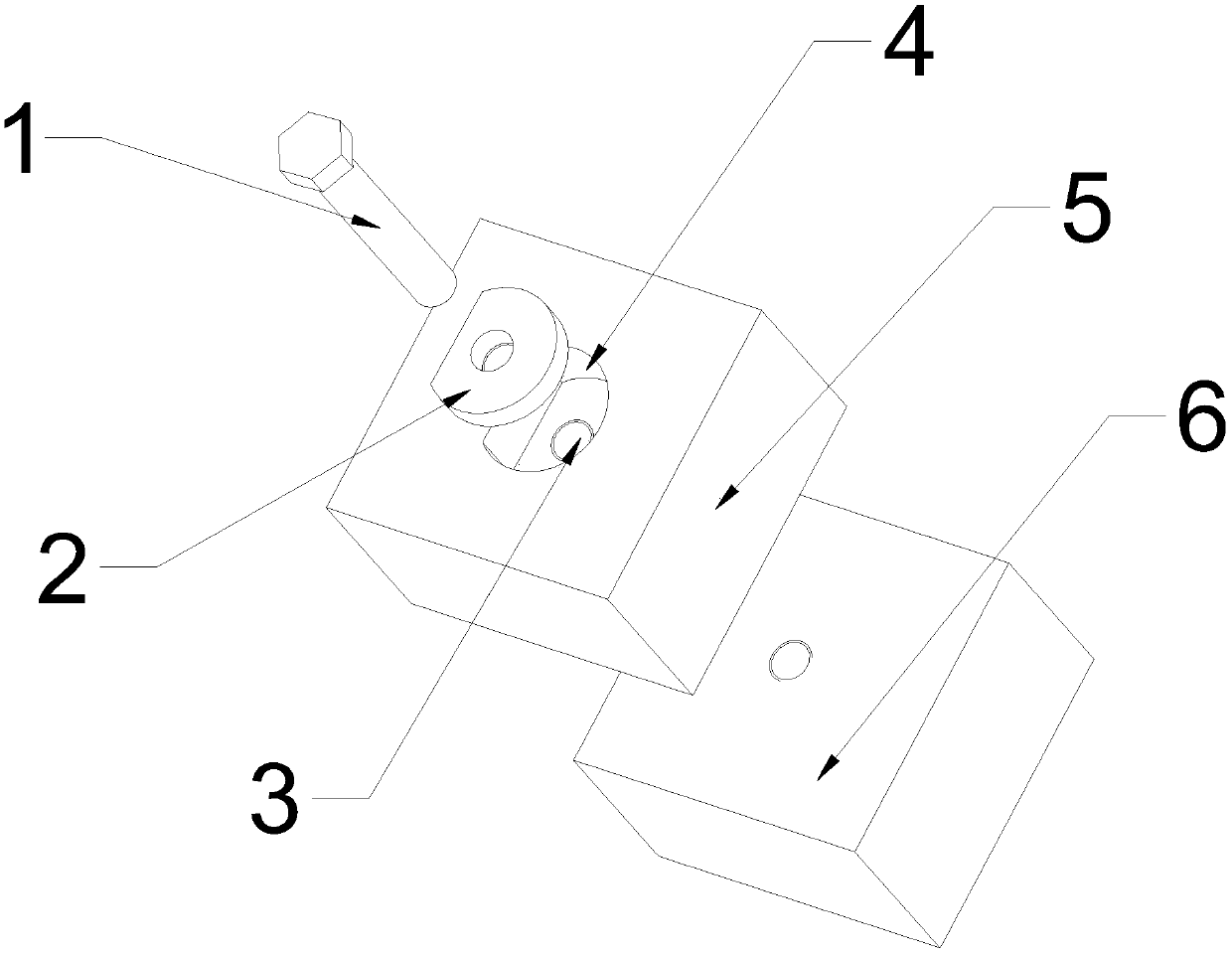

[0015] Example 1. A bolt locking structure constituted as figure 1 As shown, it includes the countersunk threaded through hole arranged on the upper workpiece, and the countersunk threaded through hole includes an upper special-shaped countersunk head 4 and a lower threaded part 3; The upper special-shaped countersunk head 4 is matched; the bolt 1 is connected with the upper special-shaped countersunk head 4 and the lower threaded part 3 through the special-shaped washer 2; the bolt 1 and the special-shaped washer 2 are welded and fixed. The bolt 1 passes through the special-shaped washer 2 and connects the upper workpiece 5 and the lower workpiece 6; the countersunk threaded through hole includes the upper special-shaped countersunk head 4 above the upper workpiece 5 and the lower threaded part 3 below the upper workpiece 5, and the upper special-shaped countersunk head 4 is used to fix the special-shaped washer 2, and the shape and size of the special-shaped washer 2 match ...

Embodiment 2

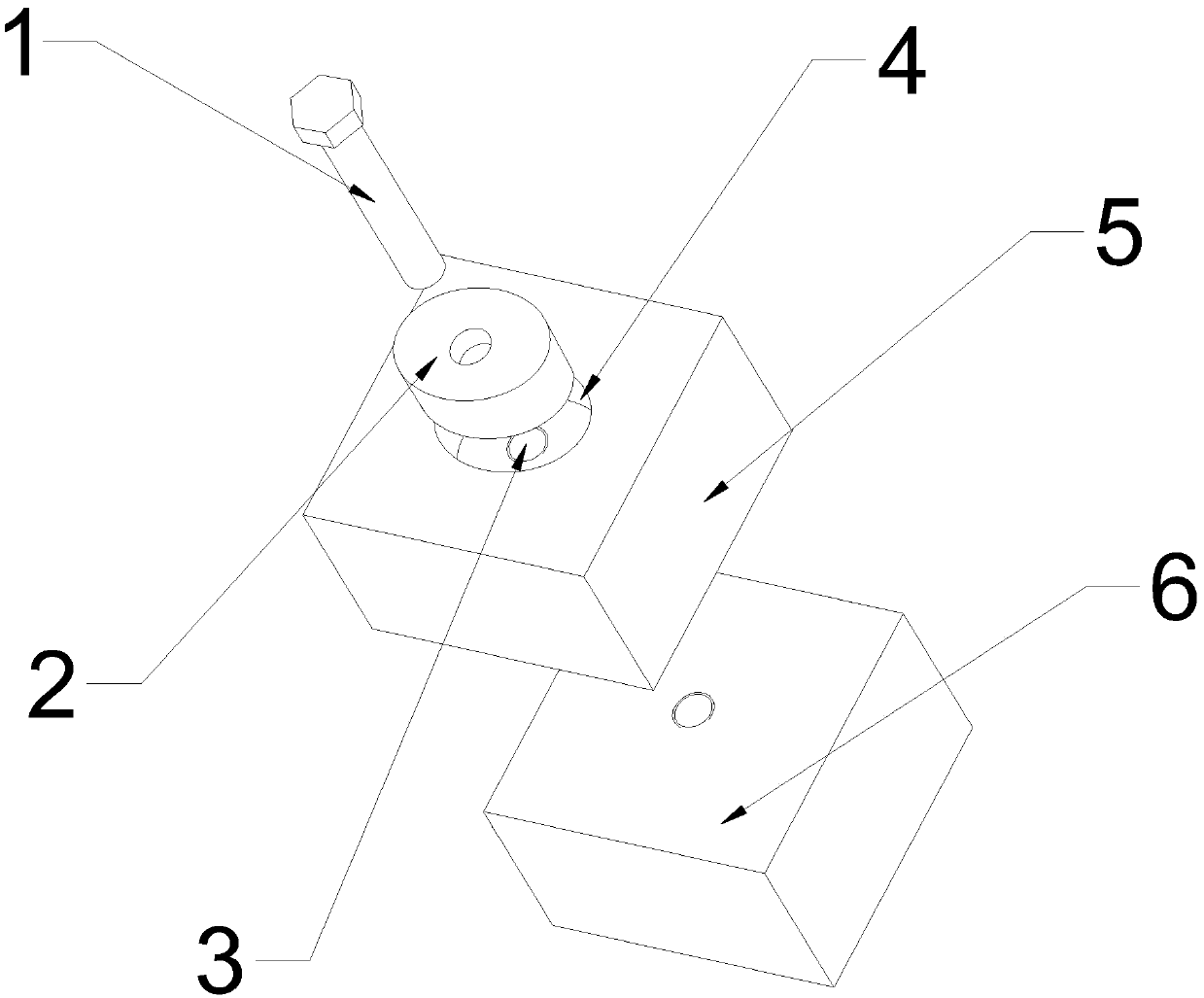

[0019] Example 2. A bolt locking structure constituted as figure 2 As shown, it includes the countersunk threaded through hole arranged on the upper workpiece, and the countersunk threaded through hole includes an upper special-shaped countersunk head 4 and a lower threaded part 3; The upper special-shaped countersunk head 4 is matched; the bolt 1 is connected with the upper special-shaped countersunk head 4 and the lower threaded part 3 through the special-shaped washer 2; the bolt 1 and the special-shaped washer 2 are welded and fixed.

[0020] The special-shaped washer 2 is a low carbon steel washer.

[0021] The special-shaped washer 2 is welded and fixed to one side of the bolt 1 .

[0022] The upper special-shaped countersunk head 4 is an oval countersunk head.

Embodiment 3

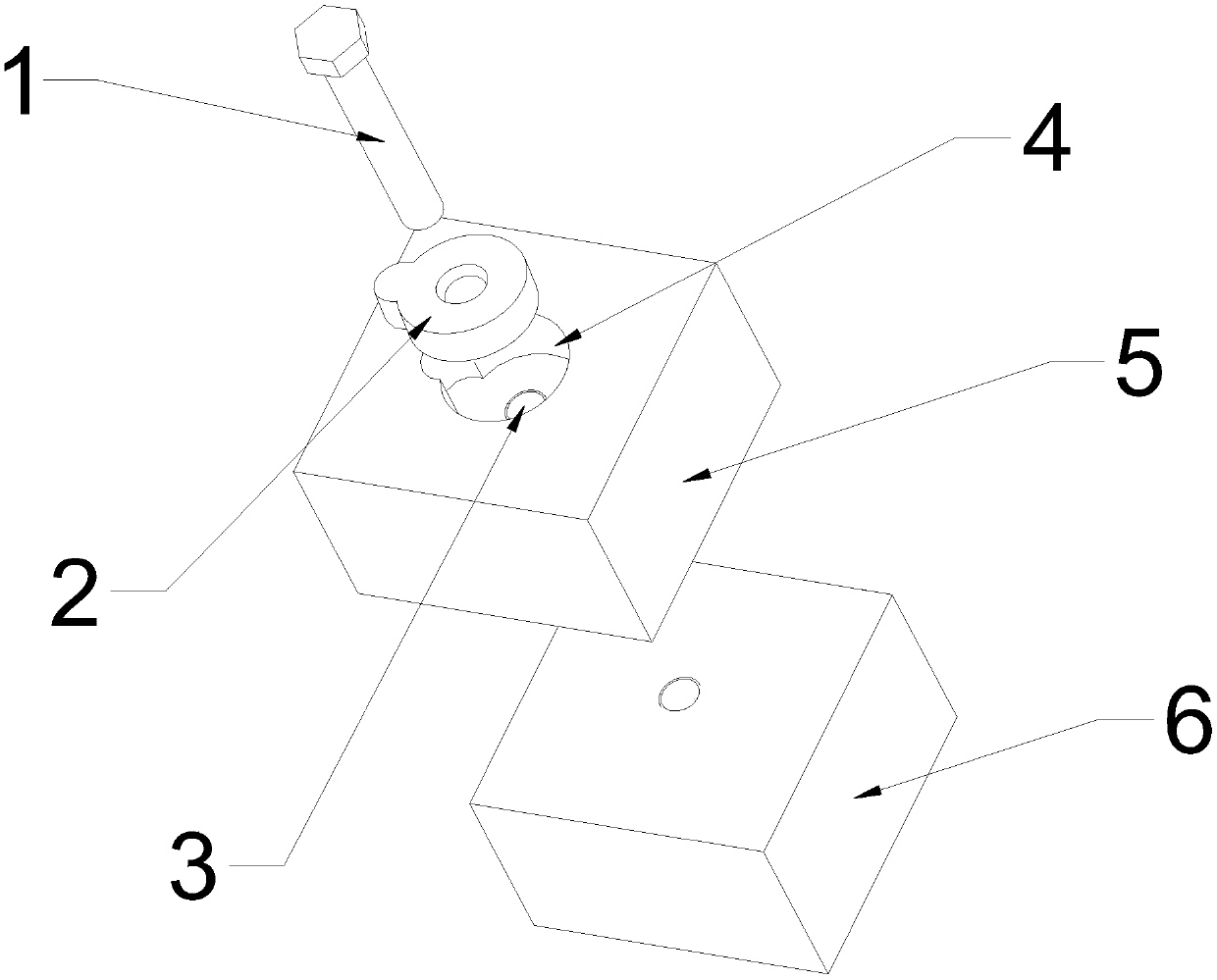

[0023] Example 3. A bolt locking structure constituted as image 3 As shown, it includes the countersunk threaded through hole arranged on the upper workpiece, and the countersunk threaded through hole includes an upper special-shaped countersunk head 4 and a lower threaded part 3; The upper special-shaped countersunk head 4 is matched; the bolt 1 is connected with the upper special-shaped countersunk head 4 and the lower threaded part 3 through the special-shaped washer 2; the bolt 1 and the special-shaped washer 2 are welded and fixed.

[0024] The special-shaped washer 2 is a low carbon steel washer.

[0025] The special-shaped washer 2 is welded and fixed to one side of the bolt 1 .

[0026] The upper special-shaped countersunk head 4 is a gourd-shaped countersunk head.

[0027] Working principle: when in use, first insert the special-shaped washer 2 into the upper special-shaped countersunk head 4 of the upper workpiece, the shape and size of the special-shaped washer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com