Industrial robot built-in wiring harness abrasion and accelerated abrasion test method and device

A technology of industrial robots and testing methods, applied in measuring devices, testing wear resistance, instruments, etc., can solve problems that are too large, do not consider wiring harnesses, cannot be integrated, intelligent, and integrated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

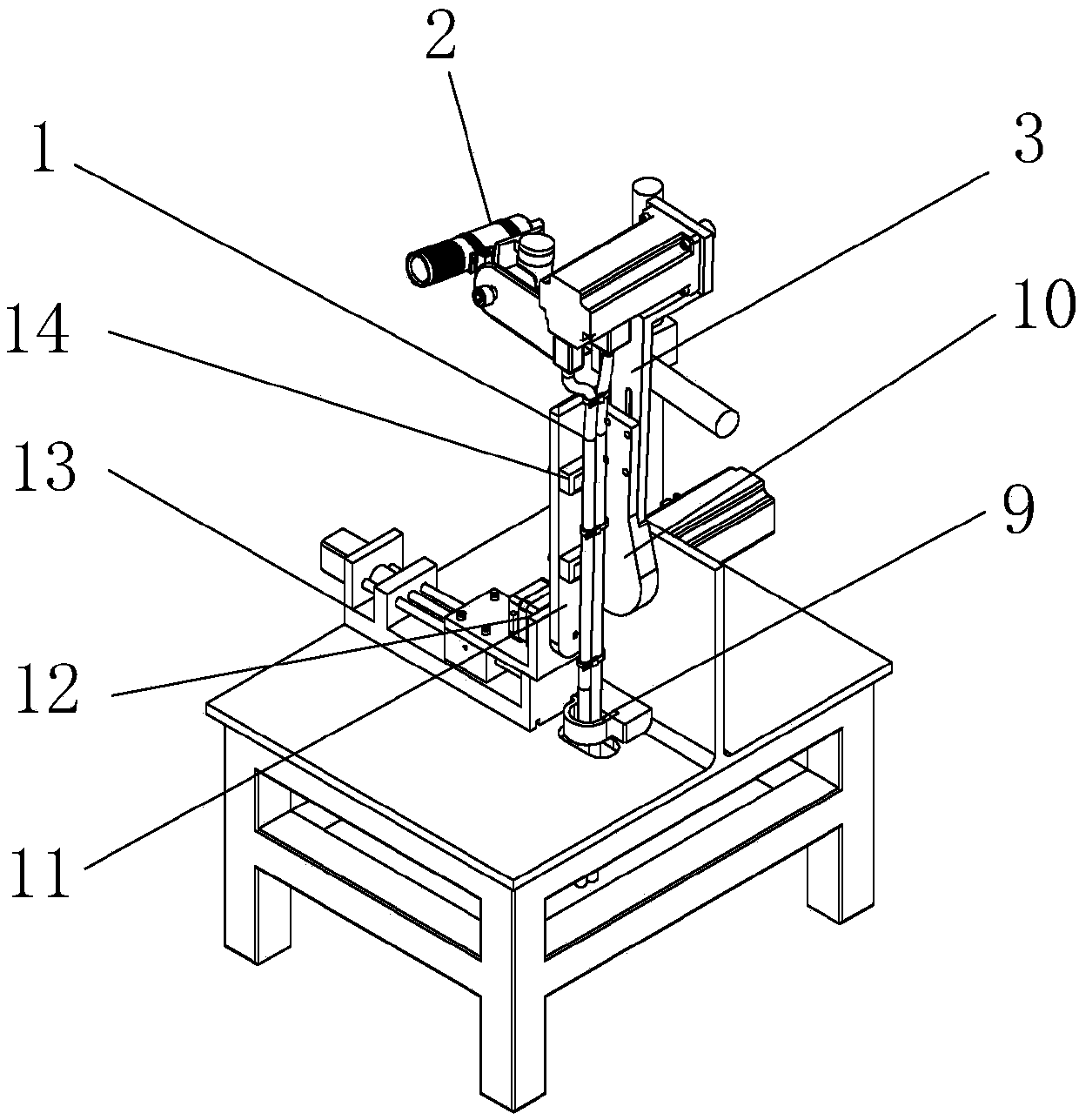

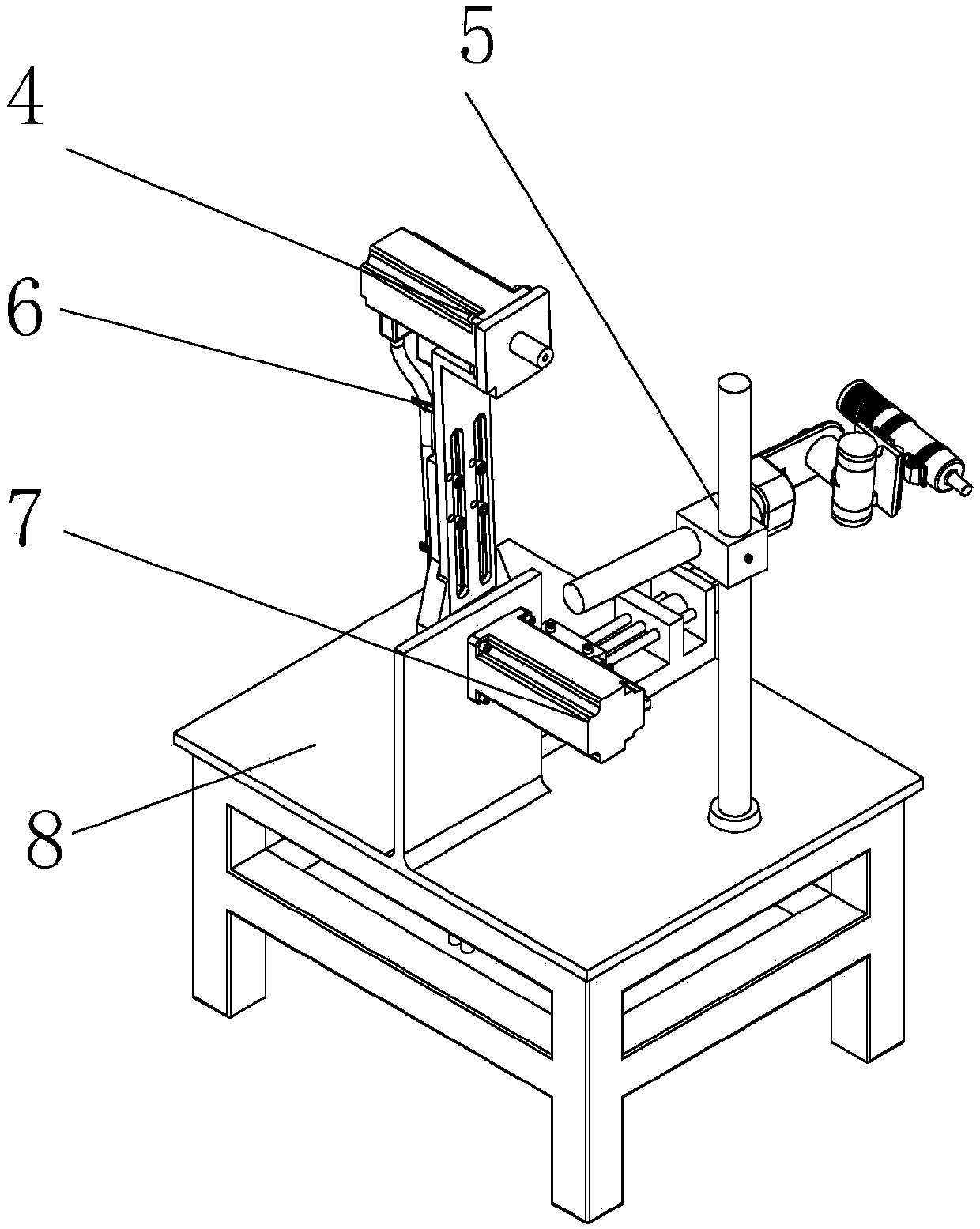

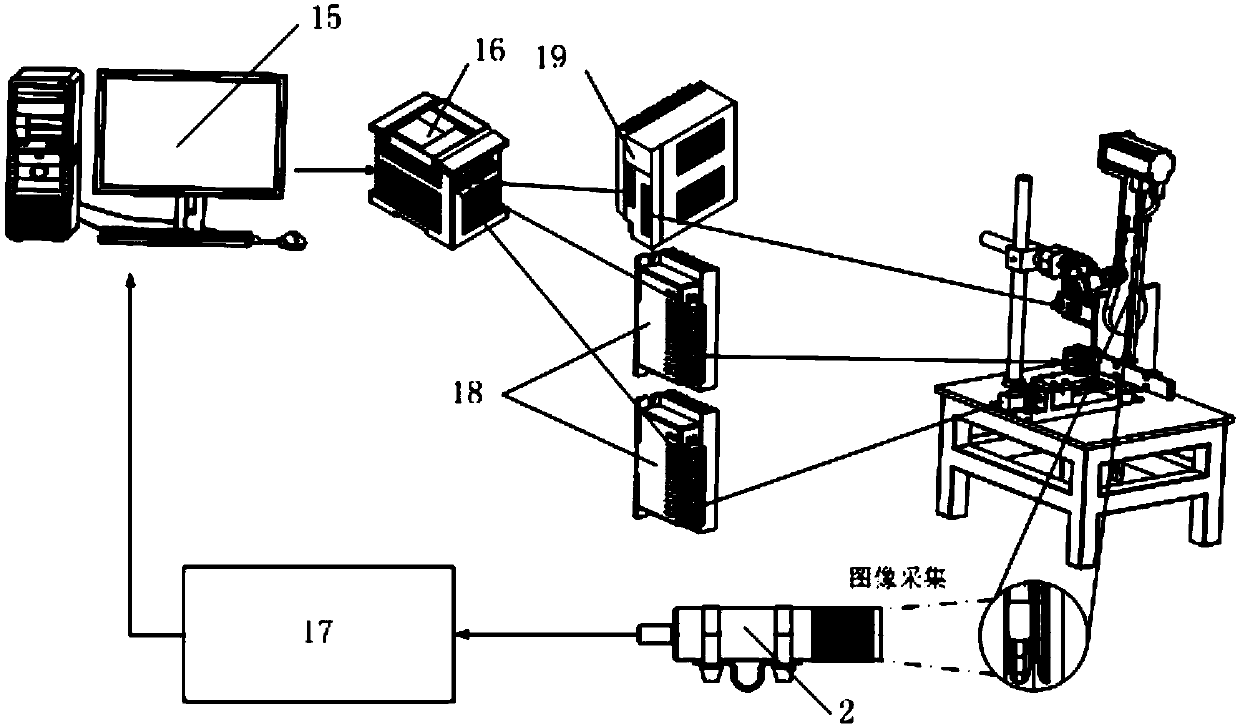

[0033] Such as figure 1 , 2 As shown in and 3, the built-in wire harness wear and accelerated wear test device for industrial robots mainly consists of multi-wire harness 1, camera 2, simulated mechanical arm 3, wire harness joint motor 4, camera spatial position adjustment device 5, multi-wire harness binding device 6, swing Motor 7, mounting base 8, hoop 9, swing arm 10, analog board 11, analog board swing and rotation device 12, analog board mobile platform 13, industrial computer 15, motor motion controller 16, swing motor driver 19, stepper motor The driver 18 and the image acquisition card 17 are composed.

[0034] The swinging and rotating device 12 of the simulation board comprises a swing angle motor and a connecting plate; the output shaft of the swing angle motor is fixed with the bottom end of the simulation board 11, and if the inside of the mechanical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com