New energy car battery box

A new energy vehicle, battery box technology, applied in electric vehicles, battery pack components, battery/battery traction, etc., can solve problems such as loss, battery box does not have the function of vibration reduction, battery box group damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

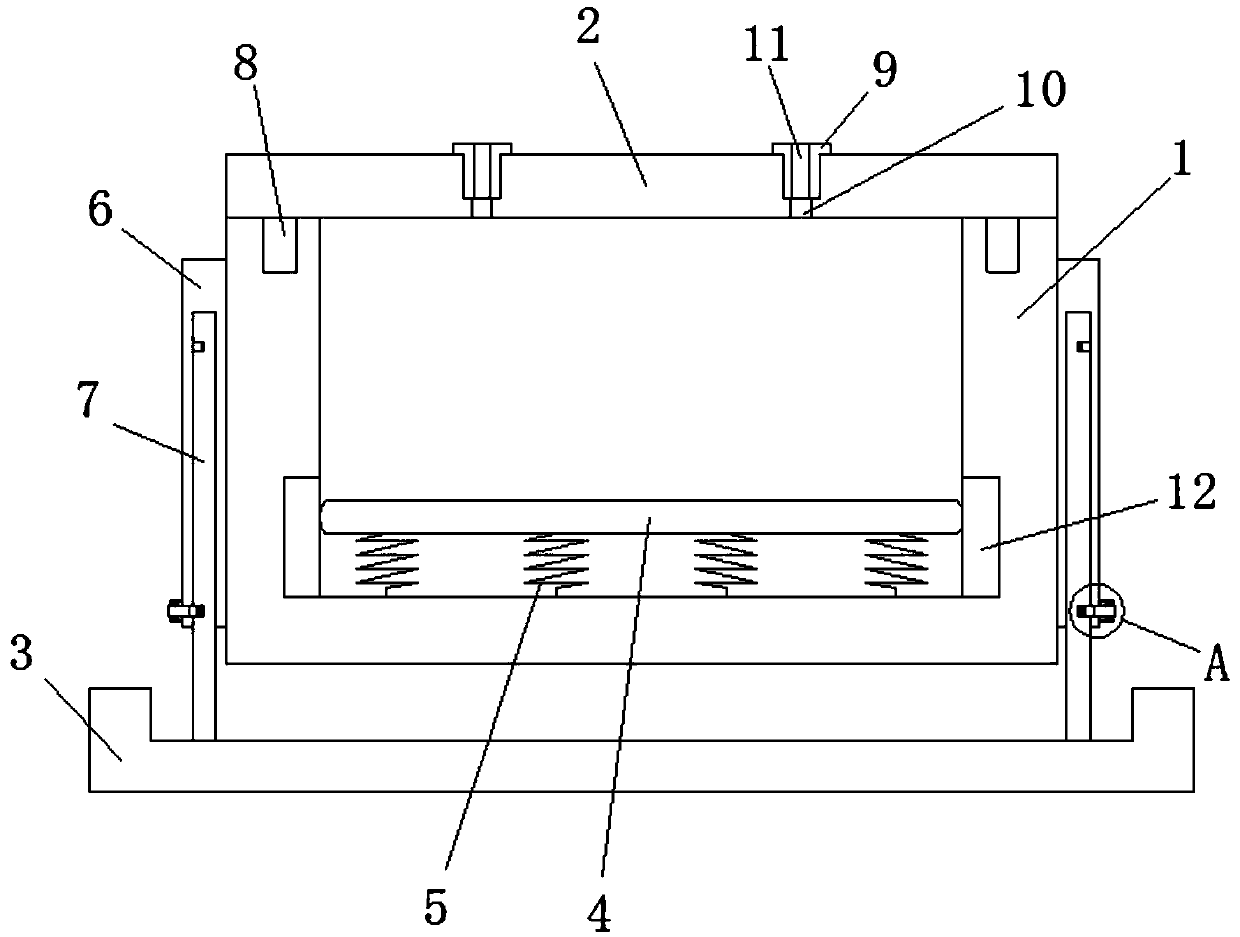

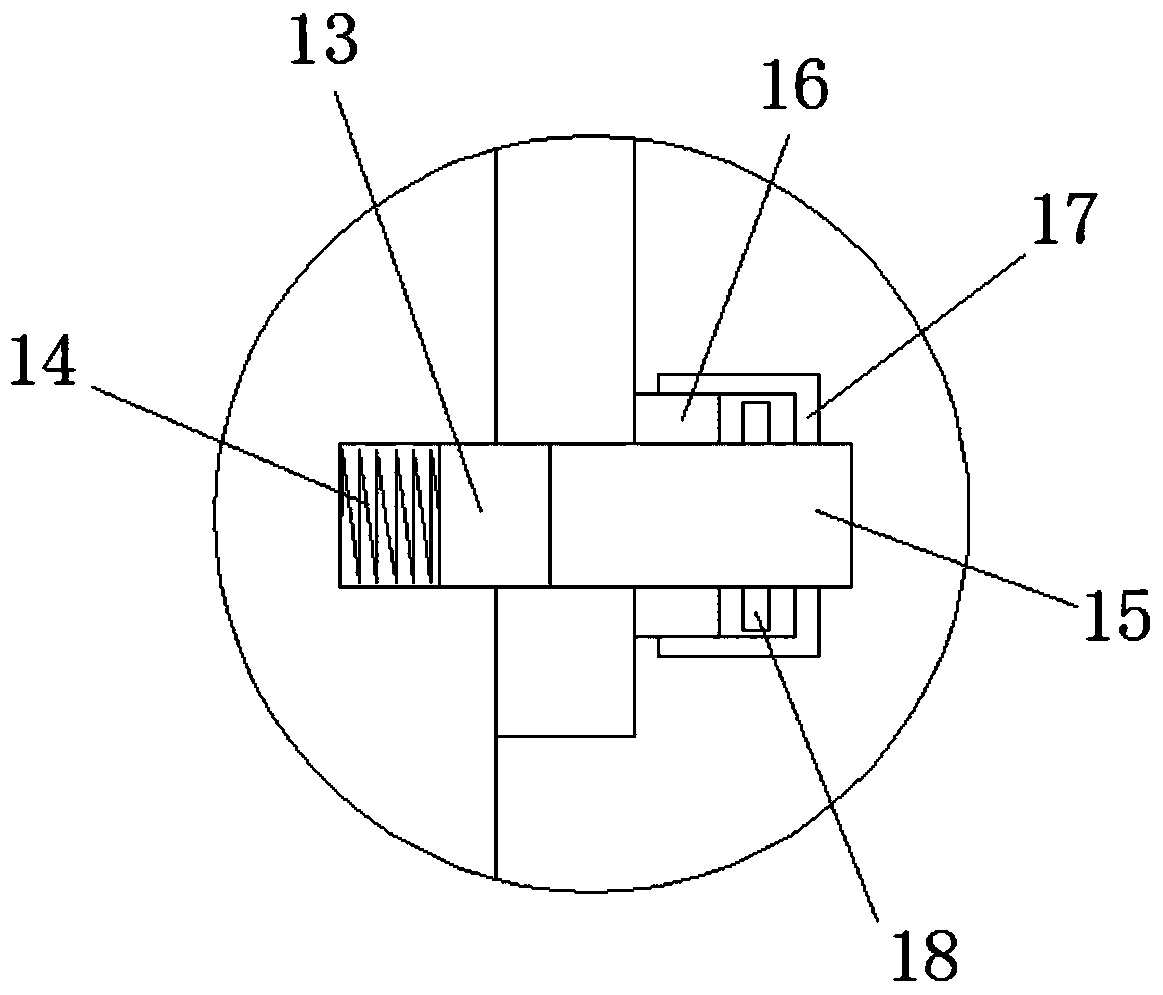

[0012] like figure 1 The shown battery box of a new energy vehicle includes an installation base plate 3, a battery box body 1 and a box cover 2. The battery box body 1 is connected to the installation base plate 3 through a height adjustment mechanism, and the box cover 2 can be Detachably connected to the top of the battery box 1, the battery box 1 is also provided with a support plate 4, the support plate 4 is connected to the battery box 1 through a buffer spring 5, the support plate 4 A rubber pad 12 is embedded on the inner wall of the surrounding battery box 1, and the box cover 2 is provided with a wiring through hole 10, and the upper end of the wiring through hole 10 is connected with a wiring terminal 9, so A through hole is also opened at the center of the terminal 9 described above. The present invention is provided with a support plate and a buffer spring in the battery box, and the impact of vibration on the battery box is reduced by the buffer spring, which pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com