Safety clamp and cargo carrying platform

A cargo platform and safety gear technology, applied in the direction of lifting devices, etc., can solve the problems of safety and hidden dangers in the cargo platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

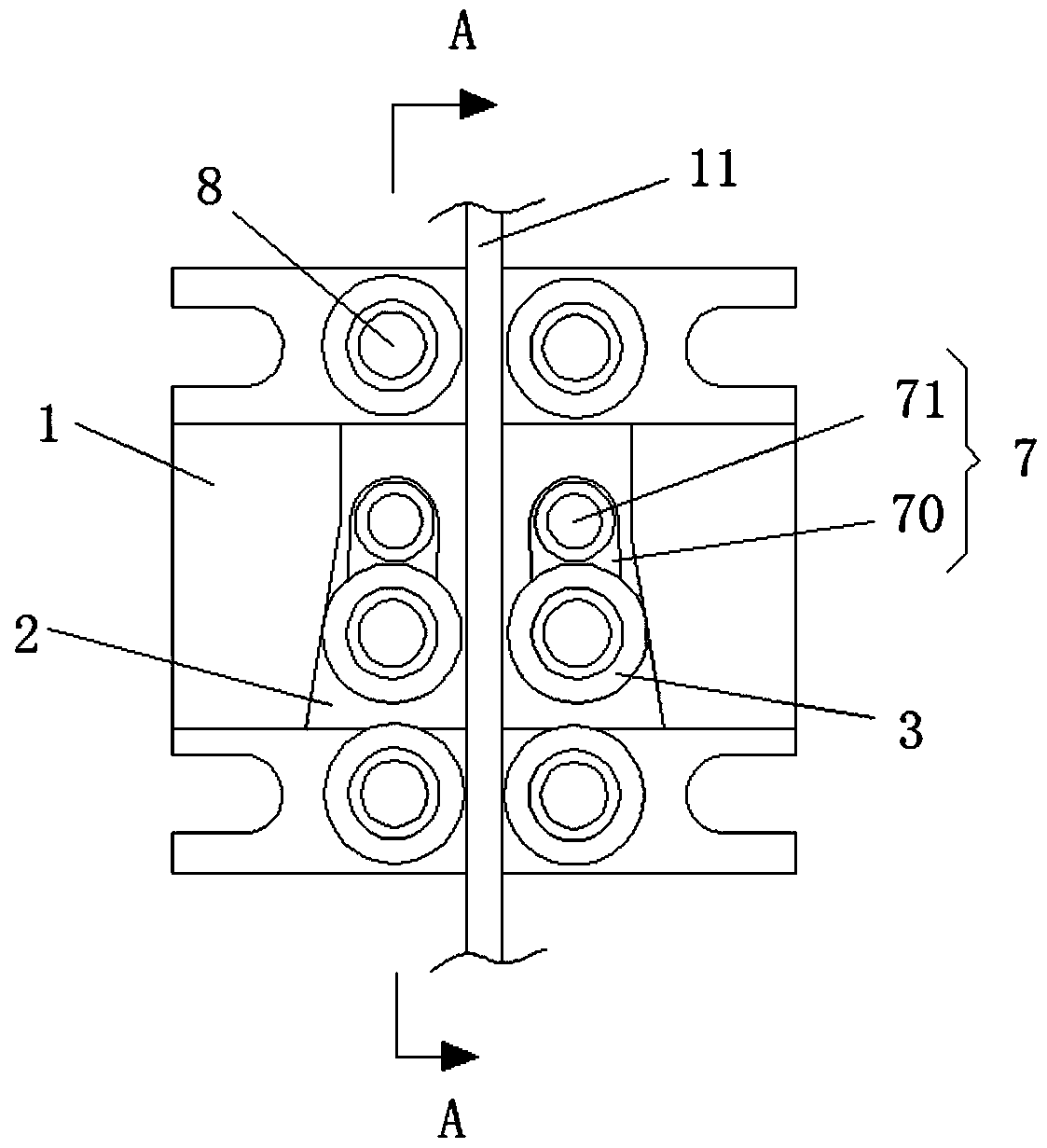

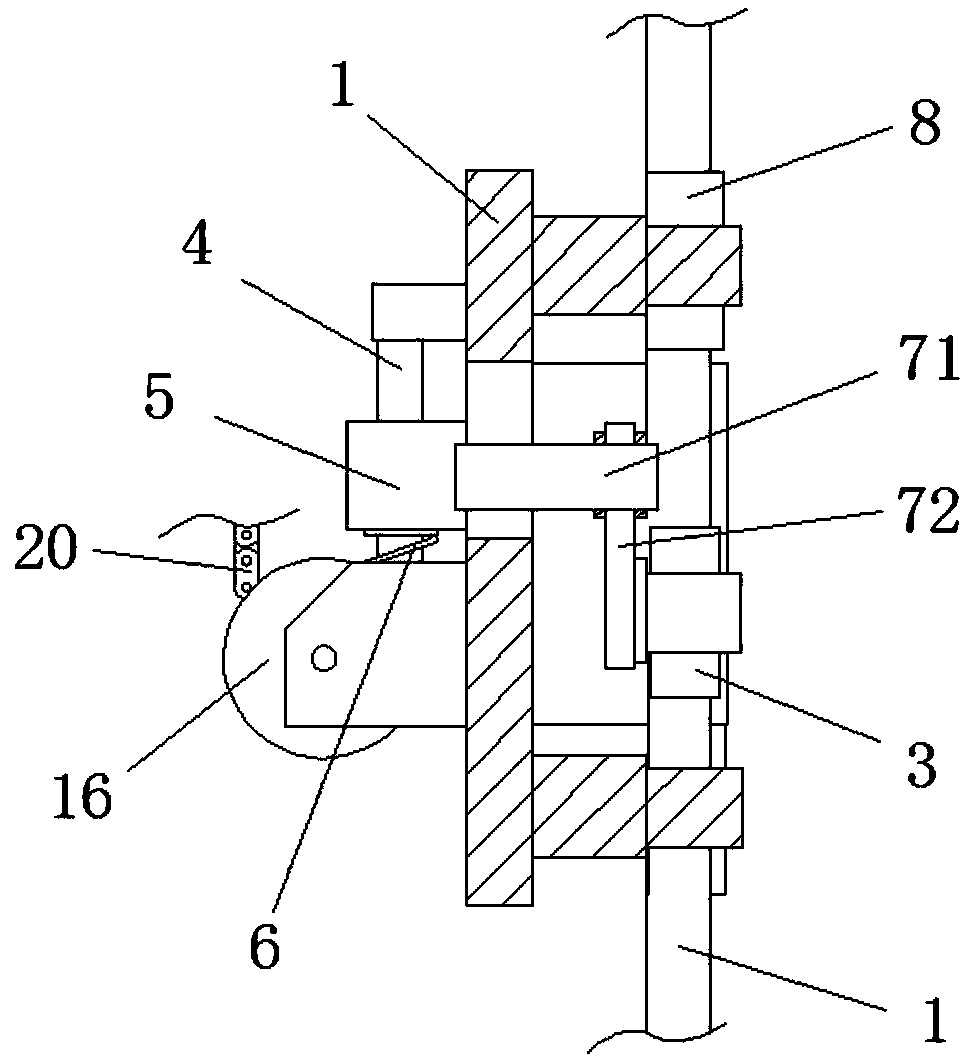

[0032] a safety gear such as figure 1 and figure 2 As shown, it includes a clamp seat plate 1, a trapezoidal guide groove 2 is provided on the clamp seat plate 1, and two brake wheels 3 rolling along the hypotenuse of the guide groove 2 are arranged in the guide groove 2, and the clamp seat plate 1 Also vertically provided with a guide rod 4 and a slide plate 5 moving up and down along the guide rod 4, the two ends of the slide plate 5 are respectively movably connected with the two brake wheels 3, and the guide rod 4 is also provided with guide grooves for guiding the slide plate 5 to The elastic part 6 that the narrow end of 2 promotes.

[0033] Through a kind of safety gear with the above structure, when it is installed on the cargo platform body 9, the guide rail 11 of the cargo platform is located between the two brake wheels 3, and the two brake wheels 3 are in the guide groove 2 The wide end of the brake wheel 3 makes the distance between the two brake wheels 3 great...

Embodiment 2

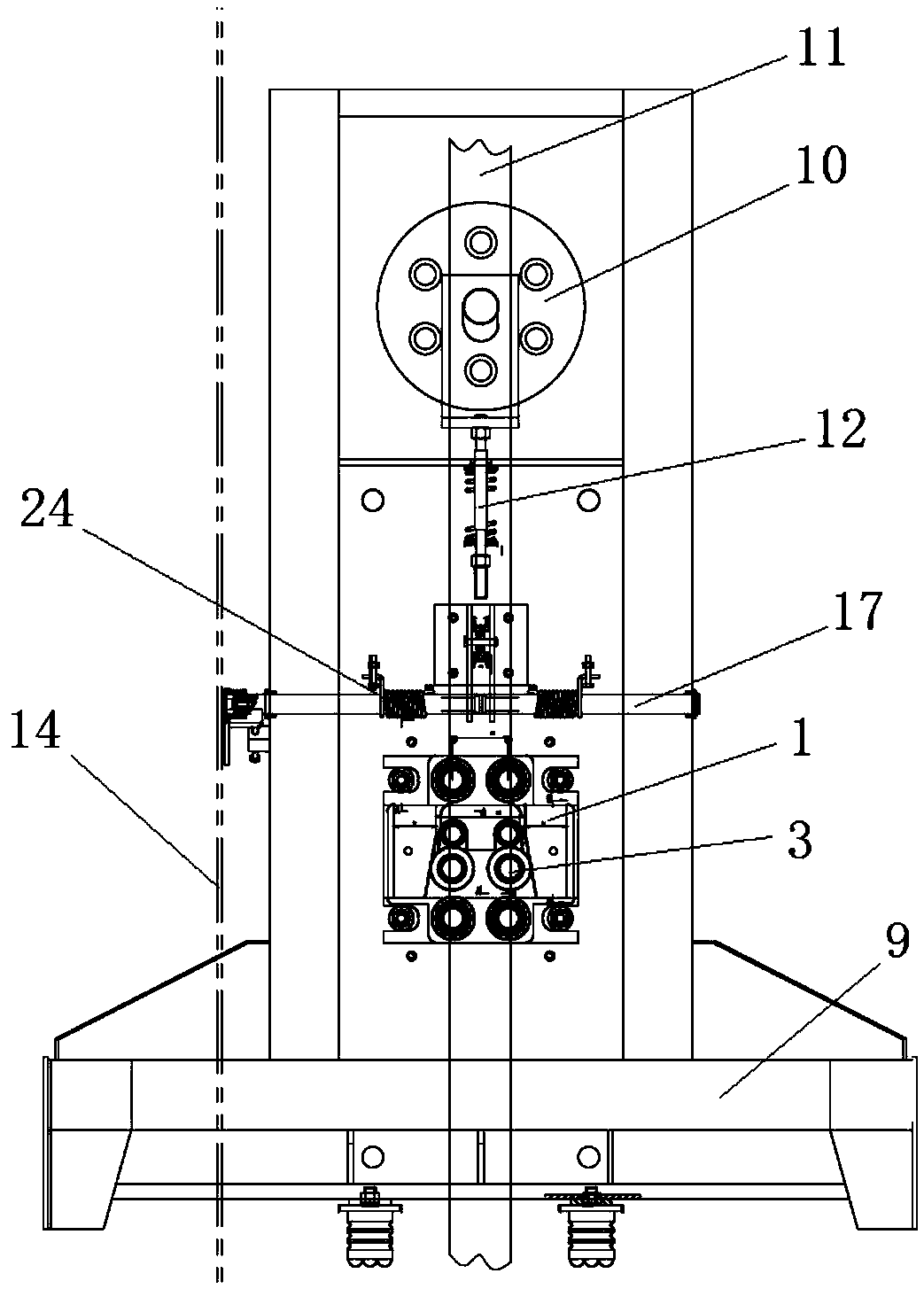

[0041] The present invention also provides a loading platform, such as Figure 1 to Figure 5As shown, the cargo platform includes a cargo platform body 9 and a speed limiting device. The cargo platform body 9 is provided with a first fixed pulley 10 that is convenient for hoisting by a traction rope. The cargo platform also includes the safety gear in the first embodiment. Clamp, the guide rail 11 of the cargo platform body 9 is located between the two brake wheels 3, and the cargo platform body 9 is also provided with a pull rod 12 that pulls the first fixed pulley 10 downward;

[0042] The speed limiting device includes a speed limiter 13, a speed limiter rope 14 and a reversing wheel 15, the speed limiter rope 14 is wrapped around the speed limiter 13 and the reversing wheel 15, the safety gear is provided with a second fixed pulley 16, and the cargo platform The body 9 is provided with a trigger device and a trigger lever 17 for triggering the safety gear. The trigger devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com