Viscose imitation silk yarn production device and spinning method thereof

A production device and production method technology, which are applied to spinning machines, continuously wound spinning machines, textiles and papermaking, etc., can solve the problems of easy wrinkling, poor shape retention of fabric pleats, and easy felting of wool fabrics. , to achieve the effect of improving strength and enhancing twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

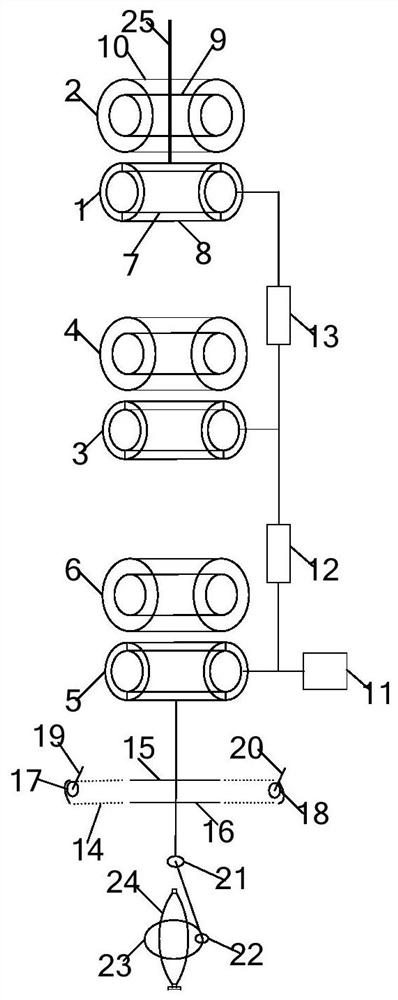

[0019] Such as figure 1 As shown, the viscose imitation silk yarn production device includes a drafting system and a winding system, and the drafting system includes a pair of rear drafting rollers, a pair of middle drafting rollers, a pair of front drafting rollers, and a pair of rear drafting rollers. Including the rear bottom roller 1 and the rear top rubber roller 2, the middle draft roller pair includes the middle bottom roller 3 and the middle upper rubber roller 4, the front draft roller pair includes the front bottom roller 5 and the front top rubber roller 6, and the rear bottom roller 1 , middle bottom roller 3, and front bottom roller 5 all include roller shaft 7, the roller shaft 7 of the rear bottom roller 1 of all spindle positions on the front car table of a spinning frame is integrated and fixedly connected, and the middle and bottom roller 3 of all spindle positions The roller shaft 7 is integrated and fixedly connected, the roller shaft 7 of the front bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com