Oil-based ink stirring device

A stirring device, oil-based ink technology, used in mixers with rotary stirring devices, mixer accessories, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

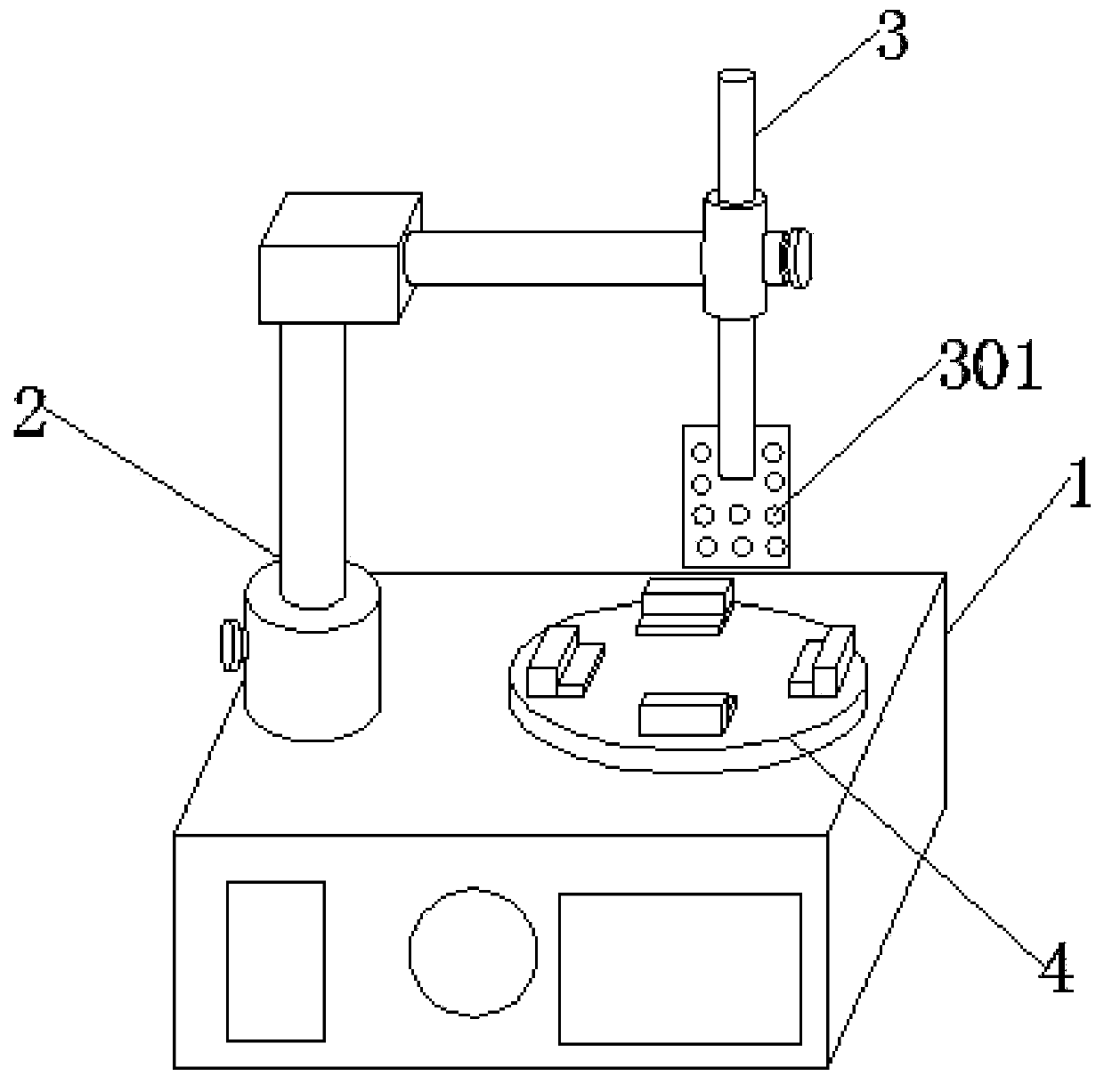

[0033] as attached figure 1 to attach Figure 9 Shown:

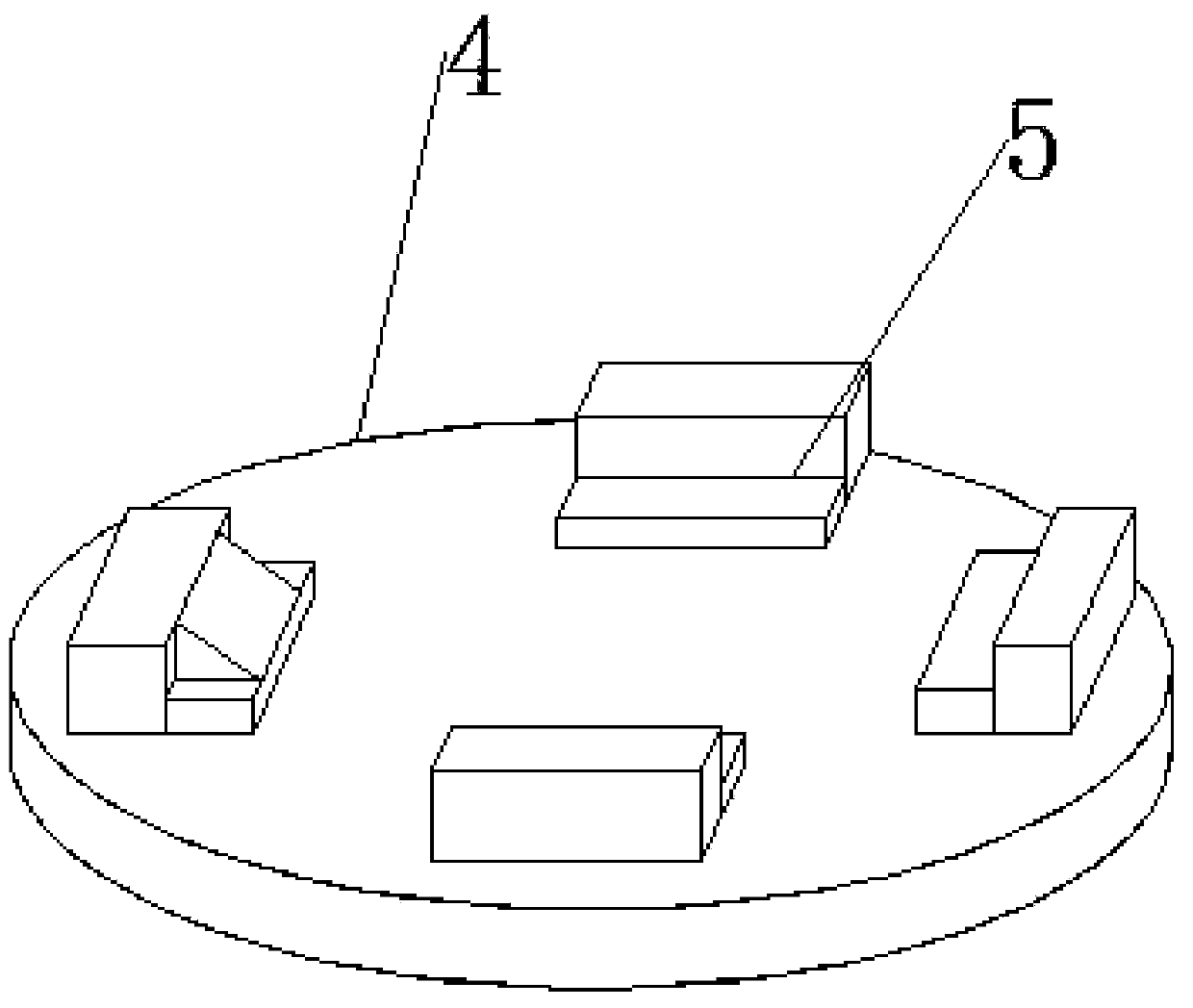

[0034] The present invention provides an oil-based ink stirring device, which includes a main body 1, a support rod 2, a stirring rod 3, a fixed base 4 and a fixed block 5. The top of the main body 1 is embedded with a support rod 2 near one side, and the top end of the support rod 2 is embedded A stirring rod 3 is provided, the bottom end of the stirring rod 3 is fixedly connected with a stirring blade 301, the top of the main body 1 is embedded with a fixed base 4, and the top of the fixed base 4 is embedded with a fixed block 5;

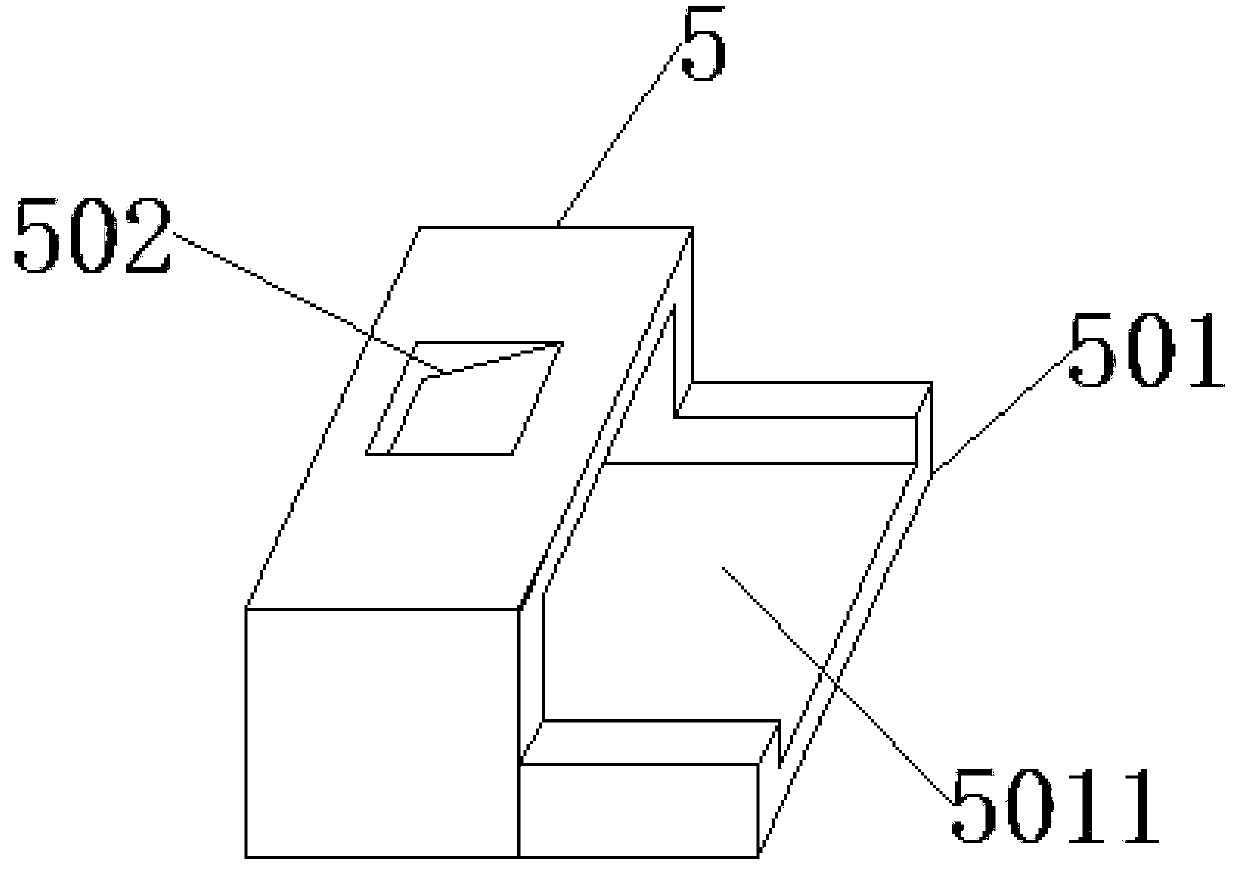

[0035] The fixed block 5 includes a placement plate 501, a socket 5011, a chute 502, a displacement block 503, a tooth mark 5031, a resisting block 504, a displacement shaft 505, a limit block 506, a slide rail 5061 and a limit rod 507, and the position plate 501 is fixed Connected to the bottom end of one side of the fixed block 5, the slot 5011 is opened in the middle of the top of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com