Forklift hydraulic system for overturning large component and control method

A technology of large-scale components and hydraulic systems, applied in fluid pressure actuation system testing, servo motor components, fluid pressure actuation devices, etc., can solve problems such as uncontrollable center of gravity, irregular shaking, sudden impact, etc., to achieve lifting Longitudinal stability, fast short-distance transition, fast and reliable compaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

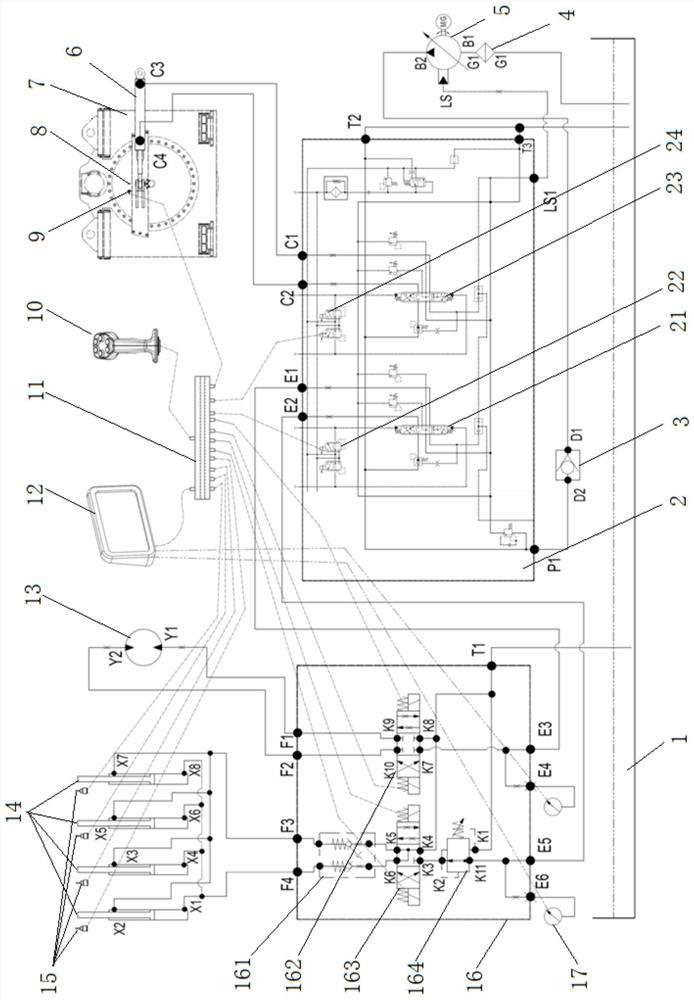

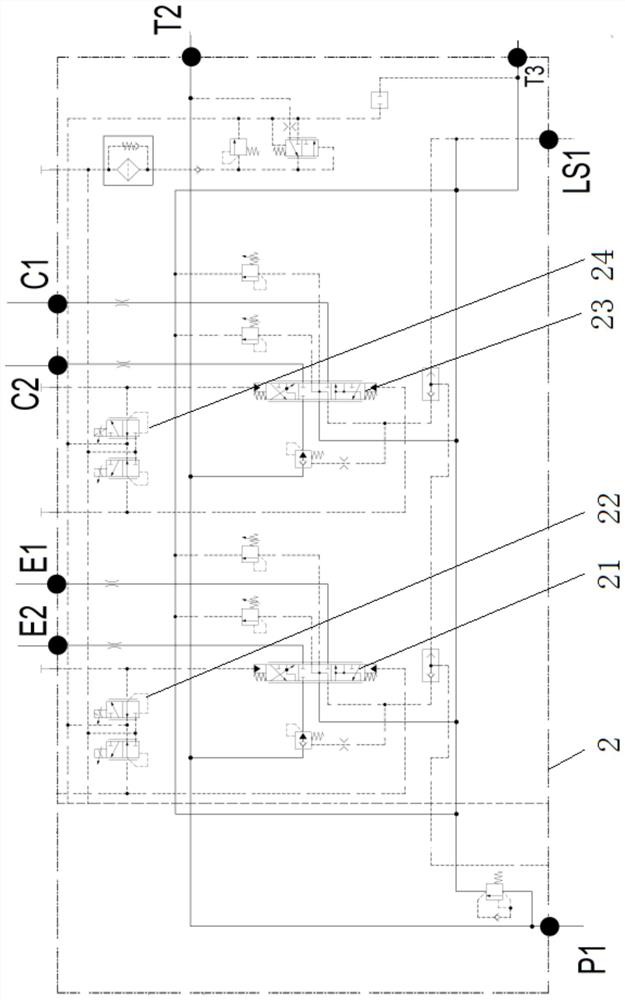

[0039] as Figure 1 As shown: forklift hydraulic system for large member flipping, comprising an electronic control handle 10, and a rotating mechanism mounted on the forklift attachment, a horizontally moving cylinder 6 and a pressing cylinder 14, the compression cylinder 14, the rotating mechanism are successively connected by the integrated valve block 16, the main multi-way valve 2 and the hydraulic tank 1 are connected to form their respective hydraulic circuits, respectively, so that the large components clamp and rotate; The main multi-way valve 2 and the horizontal moving cylinder 8 are connected to form a hydraulic circuit so that the large member is centered on the forklift attachment; The signal end of the electronic control handle 10 is electrically connected with the integrated valve block 16, the main multi-way valve 2.

[0040] Further, the rotating mechanism is a hydraulic rotating motor 13, the horizontal moving cylinder 8 of the cylinder body is fixed mounted on t...

Embodiment 2

[0071] Hydraulic control method of forklift for flipping large preform parts, which comprises the following steps:

[0072] Step 1: The pressure signal end of the main valve plate in the main multi-way valve 2 is connected with the signal end of the variable pump 7, and the pressure signal of the main valve plate is fed back to the variable pump at any time, so as to control the speed of the variable pump and the output flow of the hydraulic oil; Among them, the main pressure of the system is 225 bar during operation, the variable pump speed is controlled between 1800-1910r / min, and the output flow of hydraulic oil is accurately controlled at 46±3L / min;

[0073] Step 2: the large prefab is placed on the fork rack, the clamp button on the electronic control handle 10 is manipulated, one of the main valve plates in the main multi-way valve 2 works, the hydraulic oil is fed into the integrated valve block 16; At the same time, the spool of the second three-position four-way solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com