Meat powder processing equipment

A technology of processing equipment and meat meal, applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of low cutting efficiency and large structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

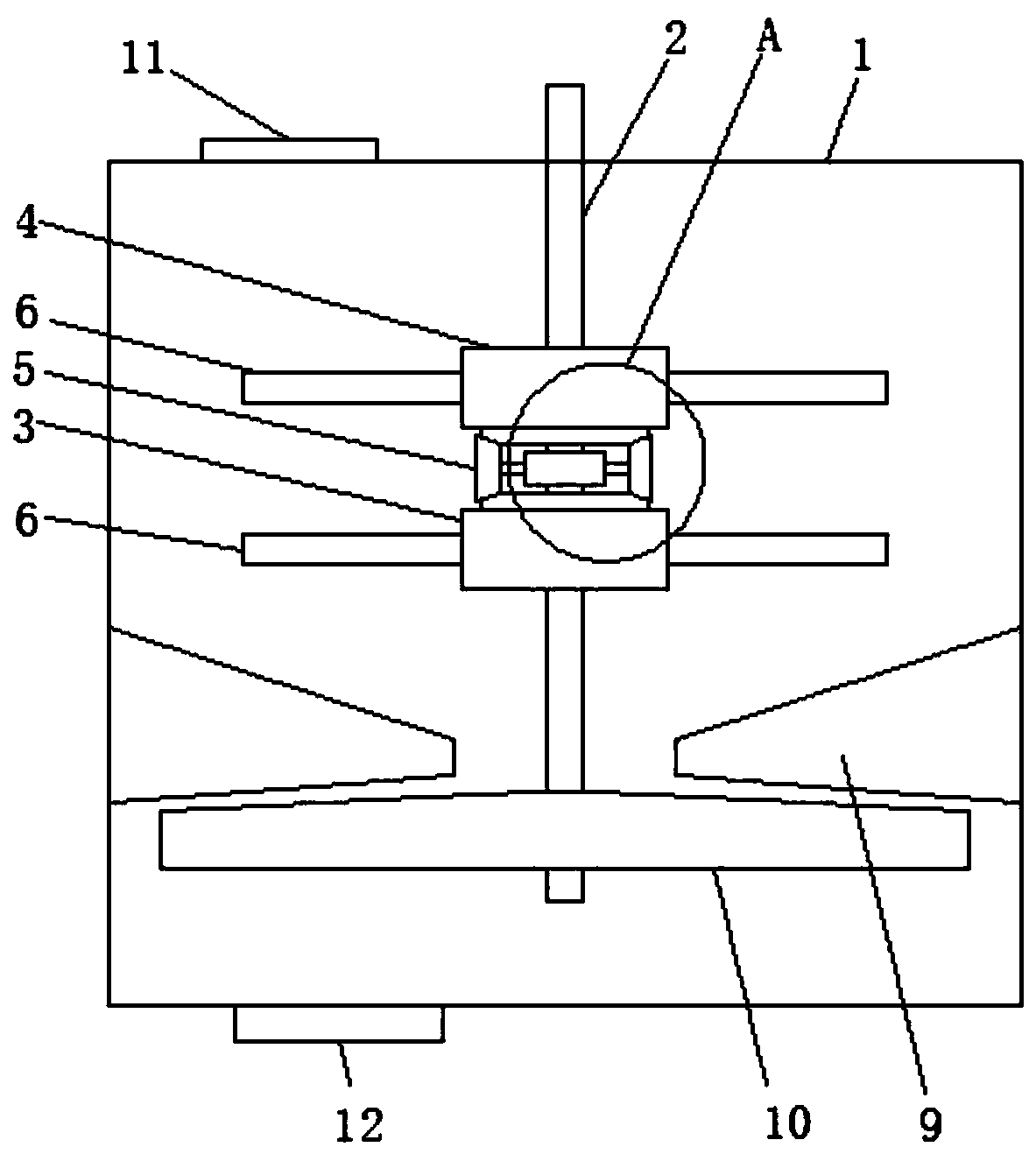

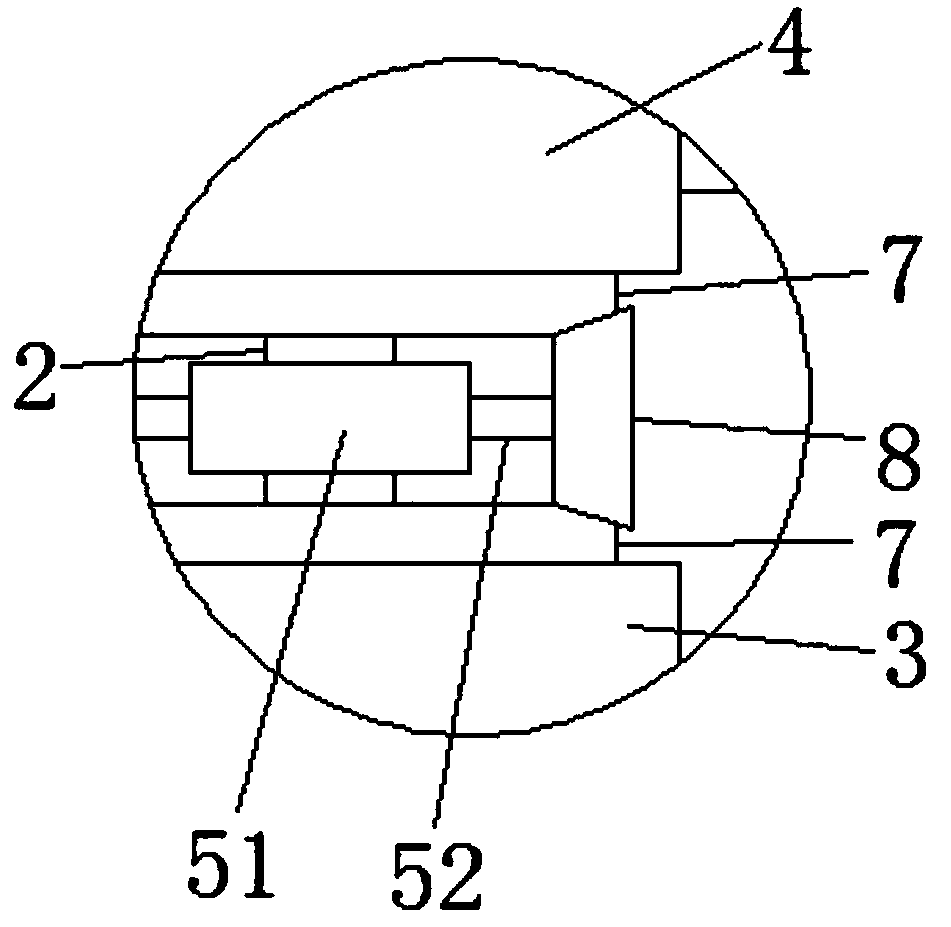

[0021] Such as figure 1 , image 3 As shown, a meat meal processing equipment includes a tank body 1. The tank body 1 includes a top wall, a bottom wall and a cylindrical side wall connected between the top wall and the bottom wall. The top wall is rotatably connected with a rotating shaft 2. The first cutterhead 3 fixedly connected with the rotating shaft 2, the transmission mechanism 5, and the second cutterhead 4 connected with the rotating shaft 2 are provided in sequence from bottom to top, and the first cutterhead 3 and the second cutterhead 4 are installed on the first cutterhead 3 and the second cutterhead 4. There is a blade 6, the first cutterhead 3 and the second cutterhead 4 are equipped with a bevel toothed disc 7, the transmission mechanism 5 includes a connecting disk 51 that is rotatably connected to the rotating shaft 2, and a fixed shaft 52 that is fixedly connected to the connecting disk 51 1. The bevel gear 8 is rotatably connected to the fixed shaft 52, a...

Embodiment 2

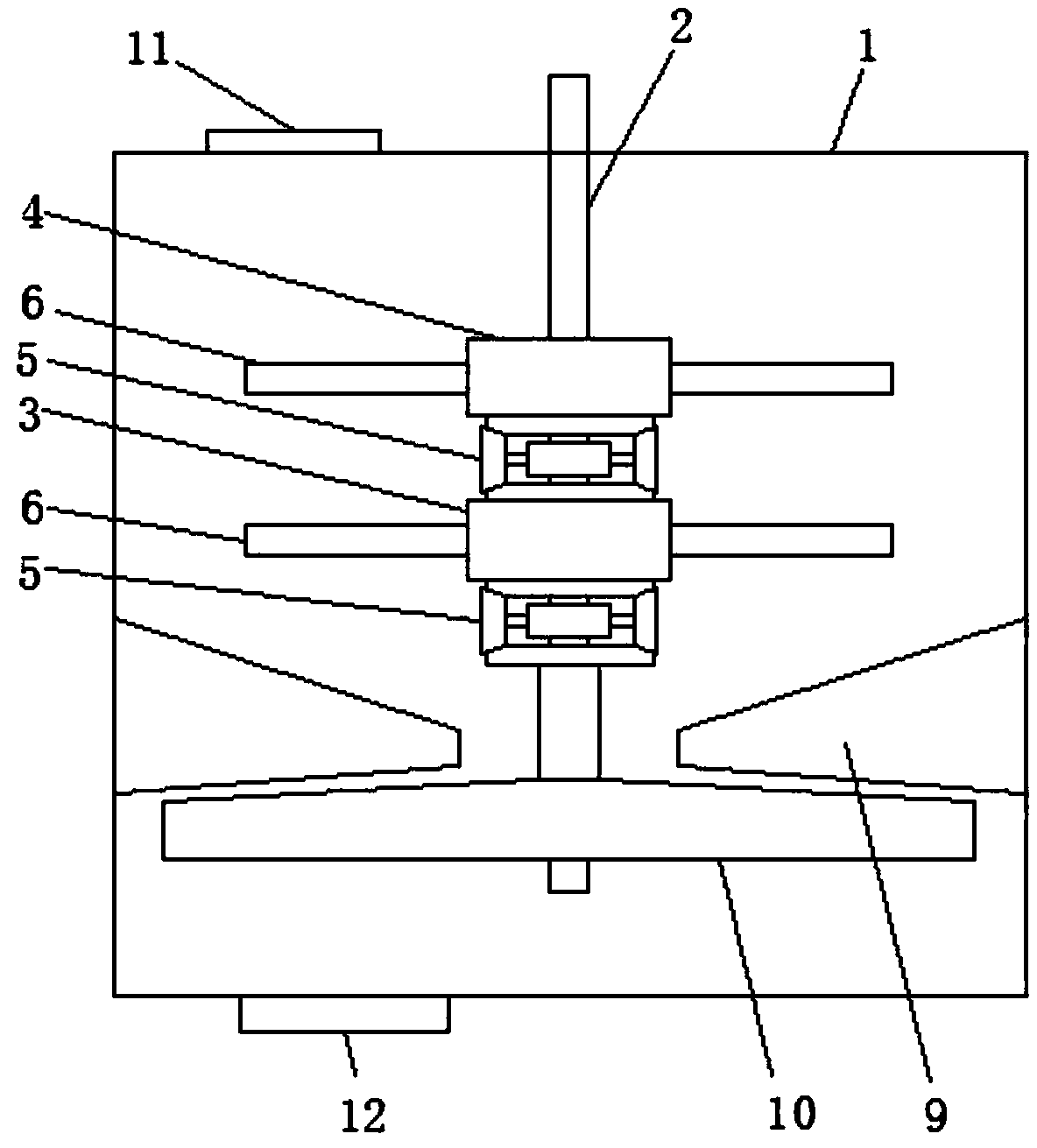

[0029] It differs from Embodiment 1 in that: as figure 2 As shown, in the present embodiment, the grinding disc 10 is rotationally connected with the rotating shaft 2, preferably through a bearing; The transmission mechanism 5 is connected. The purpose of the above arrangement is to decelerate the grinding disc 10 .

Embodiment 3

[0031] The difference between it and Embodiment 1 or Embodiment 2 is that: in order to further improve the feeding efficiency of meat material, the upper surface of the grinding disc 10 is provided with a spiral material guide groove or a spiral material guide protrusion (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com