Sectional guide rail mounting trolley of container ship transverse compartment

A technology for installing trolleys and container ships, which is applied to ship components, deck loading, ship construction, etc. It can solve the problems of high production cost, limited installation accuracy, and weak rigidity, so as to improve construction efficiency, improve installation accuracy, and reduce deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

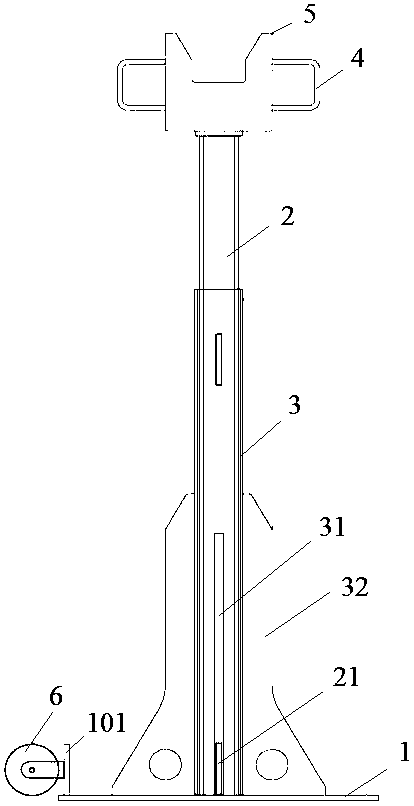

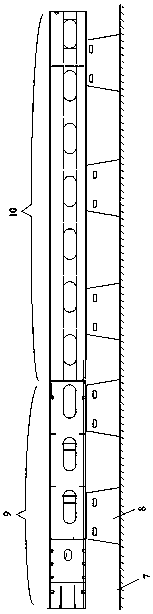

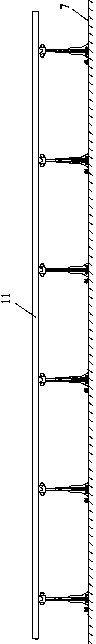

[0027] Such as Figure 1-4 As shown, the section guide rail installation trolley for the transverse compartment of the container ship in this embodiment includes a bottom plate 1, a pillar 2, a pillar sleeve 3, a pull ring 4, a bracket 5 and a wheel 6, and the pillar sleeve 3 is fixed It is arranged on the bottom plate 1, and a pillar 2 is sleeved in the pillar sleeve 3, and a mounting hole 21 is opened on the pillar 2, and an adjustment hole 31 is opened on the pillar sleeve 3, and the pillar 2 and the pillar sleeve 3 The wheels 6 are arranged on the riser 101 at one end of the bottom plate 1, the bracket 5 is fixedly arranged on the upper end of the pillar 2, and the two sides of the bracket 5 Both sides are fixed with pull ring 4.

[0028] As a preference, several support brackets 32 are provided on the outer wall of the pillar sleeve 3 in this embodiment.

[0029] As a further preference, the pipe diameter of the pillar sleeve 3 in this embodiment is 30mm-170mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com