The invention discloses a cCoil steel warehouse-out management method based on warehouse operation

A warehouse management and operation technology, which is applied in the field of coil steel outbound management based on warehouse operations, to achieve the effect of reducing time loss, reducing port detention time and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

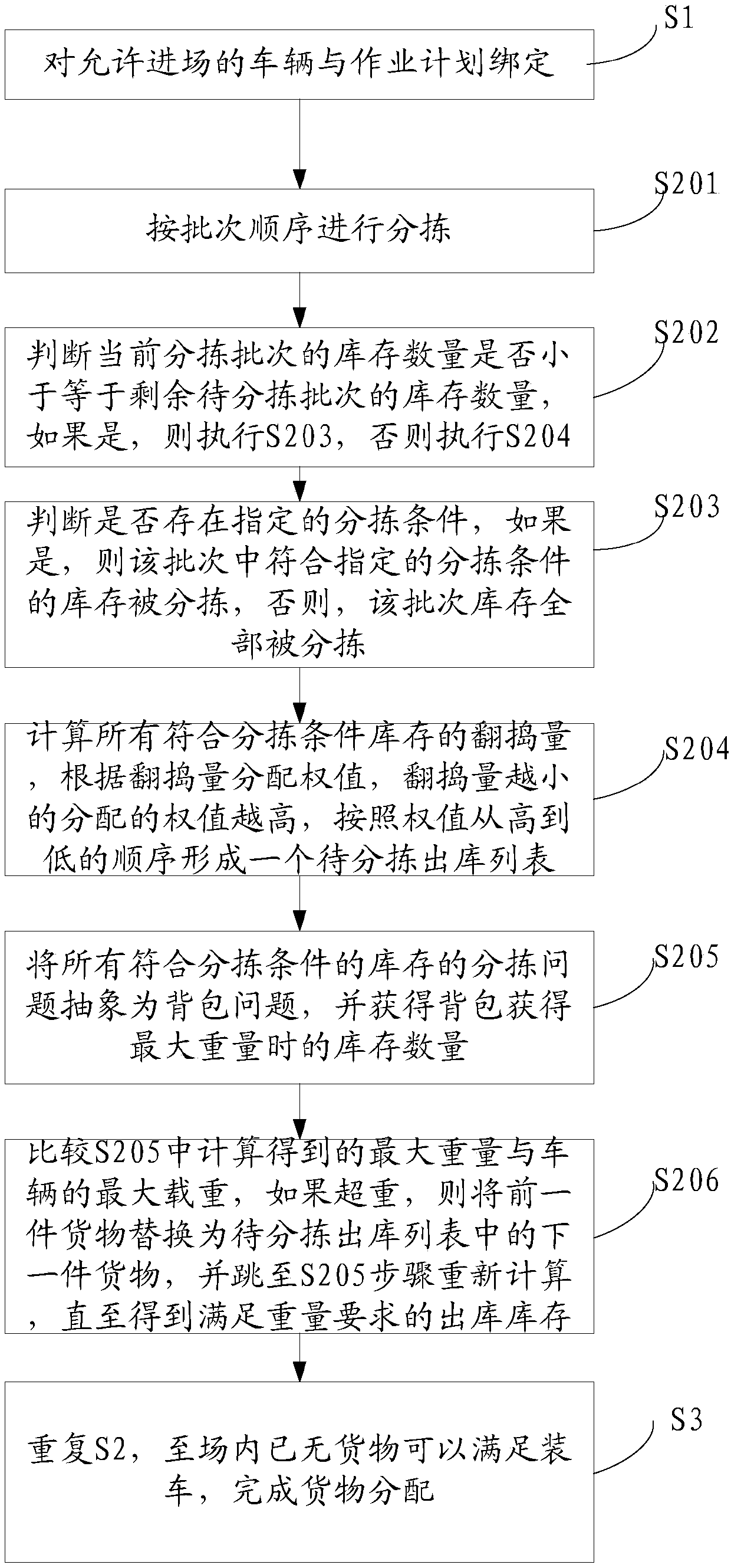

[0063] The embodiment of the present invention carries out actual operation according to the method provided by the present invention, and its process comprises the following steps:

[0064] Step 1. Bind the vehicle with the plan. The specific relationship can be shown in Table 1 below:

[0065] Table 1

[0066]

[0067] Step 2, by analyzing the outbound order, the location and information of the goods operated by the vehicle Guangdong C12345 can be determined, as shown in Table 2 below:

[0068] Table 2

[0069]

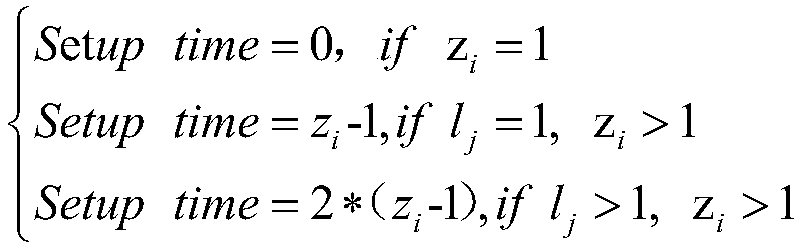

[0070] Step 3, according to the owner’s requirements for picking up the goods as follows: 0.2*1056 goods need to be fully loaded, and it can be determined that during the sorting process of the inventory, the first item of inventory in Table 2 can be fully picked and loaded on the truck, while the second item of inventory is due to the quantity If it is more, it needs to be loaded according to the remaining weight currently available. When determining the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com