Crab bucket ship unloading new technology

A new process, grab bucket technology, applied in the directions of loading/unloading, load hanging components, transportation and packaging, etc., can solve problems such as the inability to control the state, and achieve practical, reasonable and scientific methods, novel and unique designs, and improved unloading. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

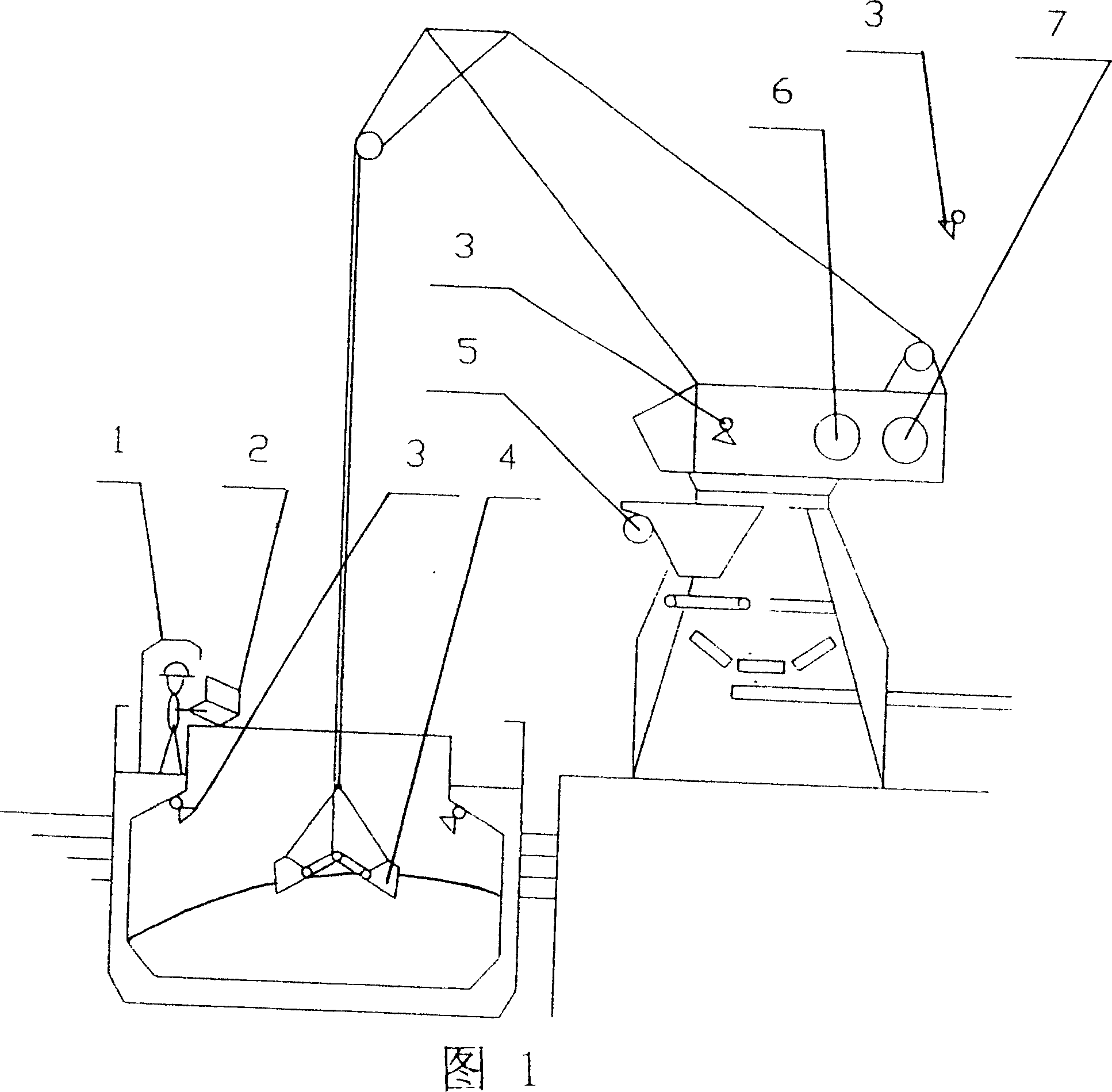

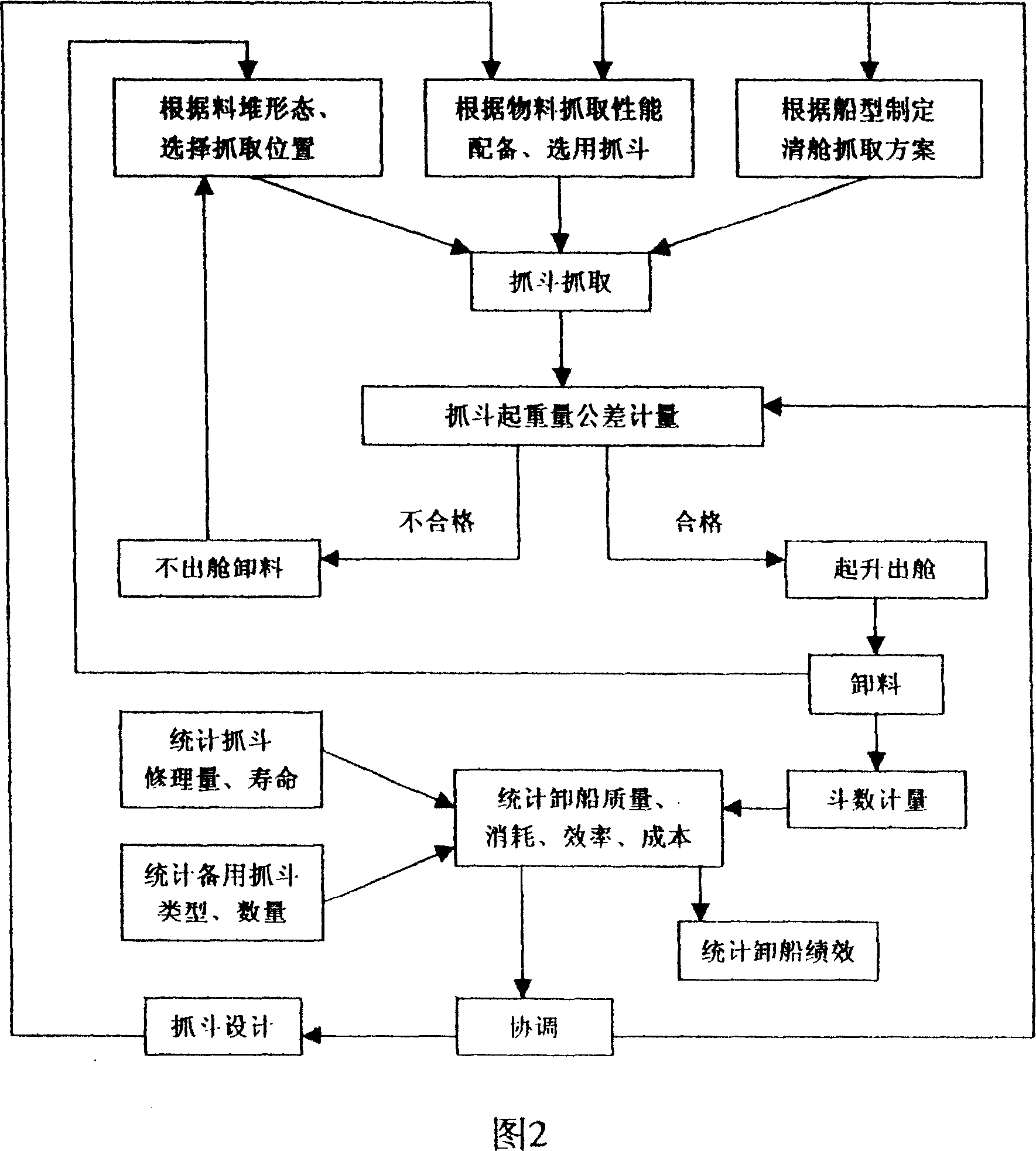

[0015] Fig. 1, Fig. 2 have described an embodiment of the present invention together, and in this example, first select and configure the appropriate grab bucket 4 according to the grasping performance (bulk density, lumpiness, hardening degree etc.) of the material. Then the driver's cab 1 is moved to a safe position outside the positive projection of the crane arm operation - on the side deck of the cabin hatch, the driver can directly see the filling situation of the material and the grab bucket in the cabin. Then, the driver selects the appropriate grab position and grab method according to the material accumulation conditions. Utilizing the information sent by the grab weight tolerance metering device, the driver decides to unload the grab, close the dump after letting go of overweight materials, or re-grab when the grabbing amount is too small. The grab weight tolerance measurement device is controlled by a computer remote control 2 with a display screen. The grab weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com