Pneumatic control unit of excrement collecting system for bullet train

A technology for collecting and moving trains, applied in the field of collecting systems, can solve the problems of ineffective management, affecting the quality of train service, and maintaining maintenance work, so as to improve the integrity rate and reliability, save railway operating costs, and save maintenance hours. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

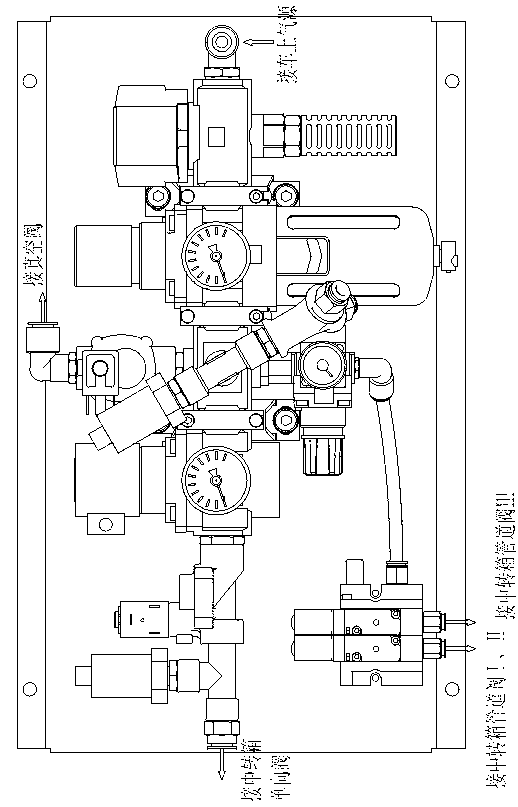

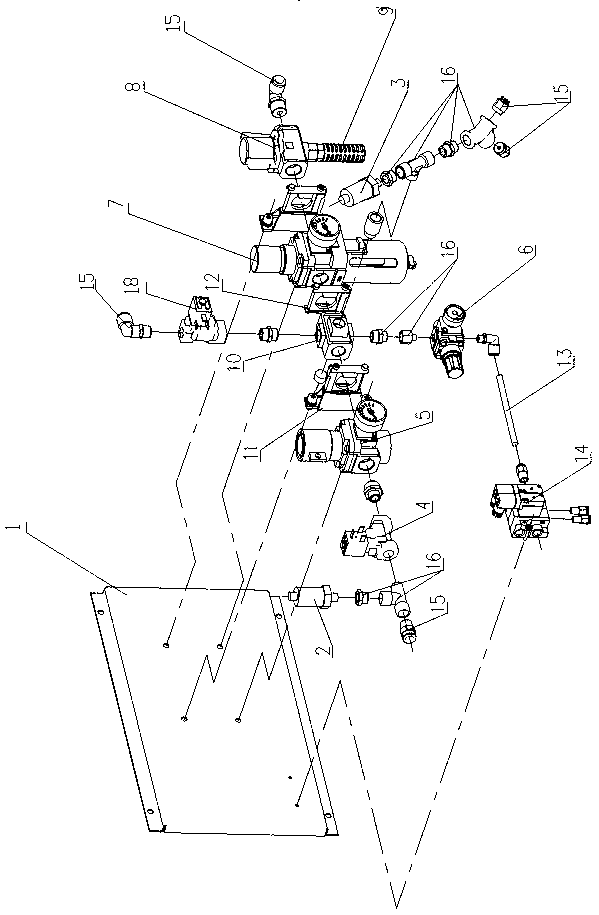

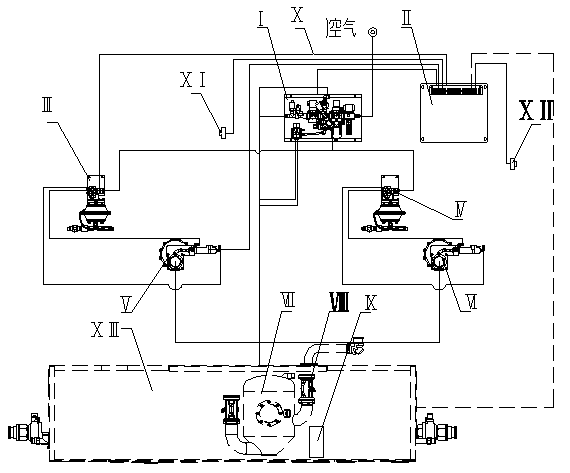

[0014] like figure 1 As shown, the pneumatic control unit of the feces collection system for motor vehicles includes a mounting plate 1, on which hexagonal nuts are welded for fixing various parts, and on the mounting plate 1, a stop valve 8, a main filter reducing valve are installed in sequence from right to left Pressure valve 7, four-way partition 10, 120kPa pressure regulating valve 5, A solenoid valve 4, 120kPa pressure detection switch 2, a vacuum solenoid valve 18 is set on the upper part of the four-way partition 10, and a vacuum solenoid valve 18 is set on the lower part of the four-way partition 10 450kPa pressure regulating valve 6, a 400kPa pressure detection switch 3 is set in the middle of the four-way partition 10, and a transfer box VII pipeline valve VIII control solenoid valve group 14 is set on the left side of the 450kPa pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com