A multifunctional cutting machine

A cutting machine, multi-functional technology, applied in the direction of work accessories, metal processing, manufacturing tools, etc., can solve the problems of height, angle cannot be adjusted, rigid damage, single function, etc., to increase cutting function, reduce rigid damage, improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

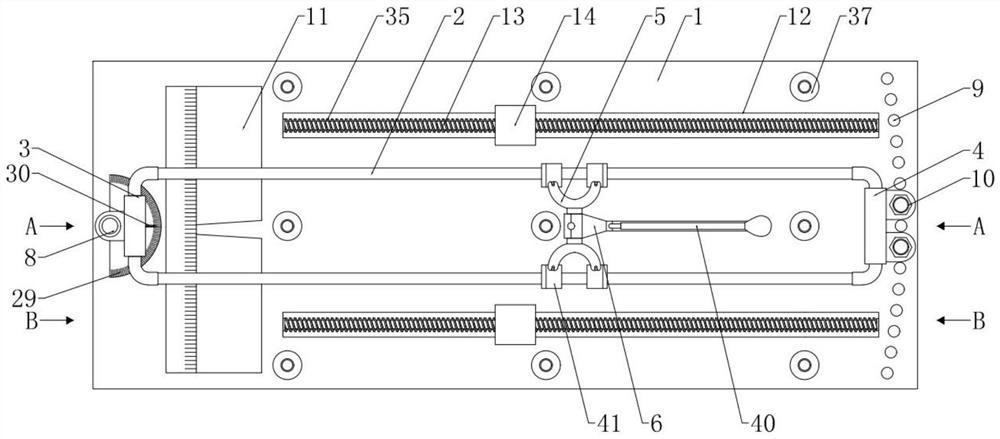

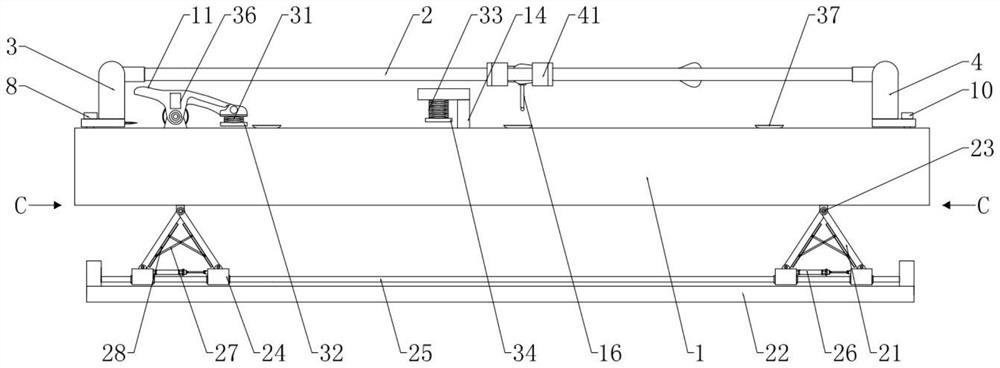

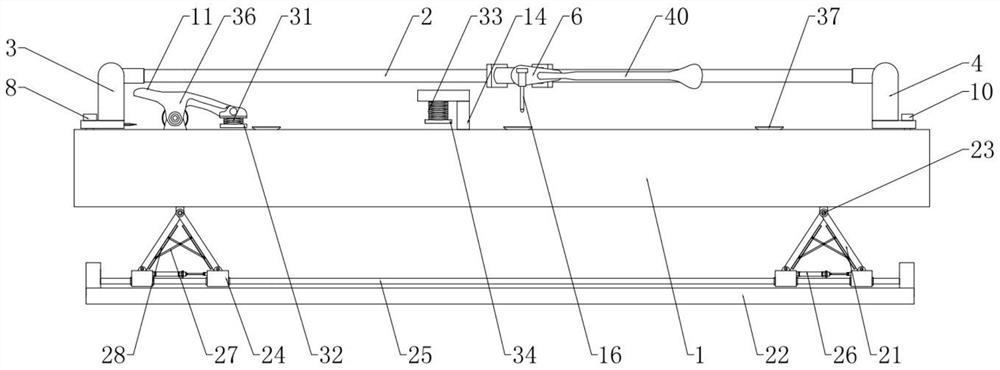

[0042] Embodiment: When the plate to be cut needs to be cut, first, the clamping part 14 is moved to the side of the rectangular groove 12 away from the clamping body 11, and one side edge of the plate to be cut is inserted into the clamping part 14 Open end, and the edge of the other side of the plate to be cut can be clamped and positioned by the clamp body 11, so as to realize the simultaneous positioning of the opposite sides of the plate to be cut, which not only improves the stability of positioning, but also improves the stability during the cutting process. accuracy; when it is necessary to cut the plate to be cut, the bottom of the cutting knife is in contact with the surface of the plate to be cut, and the cutting knife is moved linearly along the guide rod 2 by pulling the pressing handle 40, and finally the plate to be cut is effectively cut by the cutting knife Cutting, wherein the cutting knife has a telescopic function, and the length of the cutting knife can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com